10 6月 20 Ppi Cff

20 ppi Cff for efficient deep slag removal technology

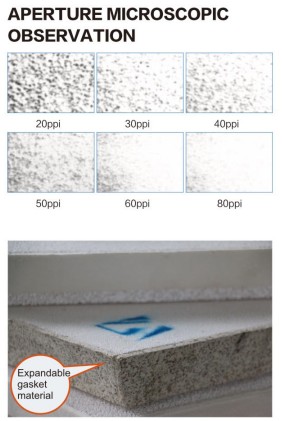

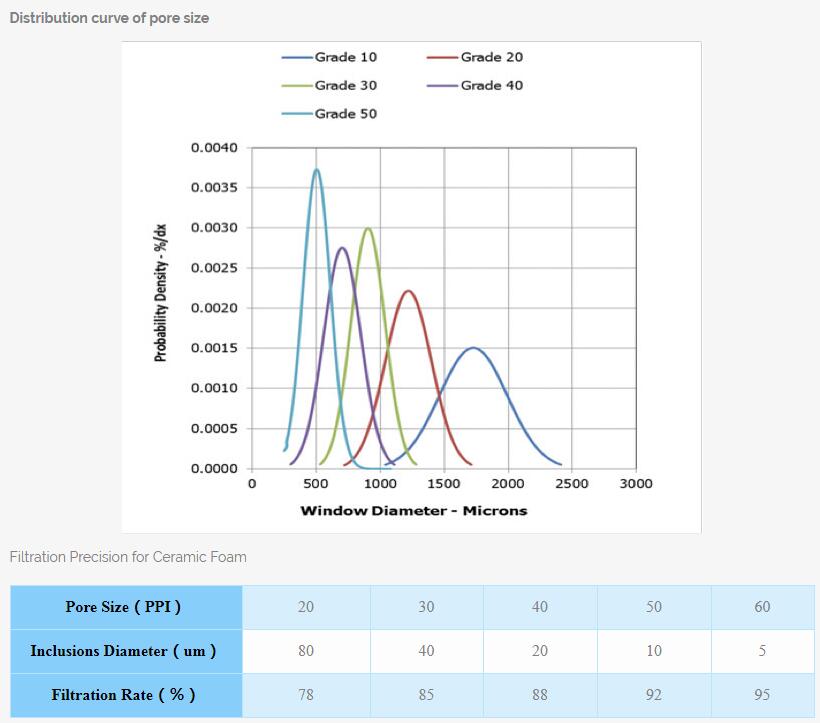

Research and development of low-cost, easy-to-operate ultra-fine pore size, high-strength ceramic foam filter plates that do not drop ceramic particles (such as Adtech Cff), and researched the patented technology of two-stage filtration of deep filter residue.

20 Ppi Cff is the best choice for high-quality aluminum, and it is a good measure to solve the problem of pinholes, burrs and black spots.

Two-stage filtering feature

Put 20 Ppi Cff and 40 ppi Cff up and down in the same filter box, and design the two-stage spacing according to the flow rate. According to product requirements, single or double can be flexibly used.

Two-stage filtering effect

When aluminum passes through the first-stage distribution-integration process, it is a very good alloying process. At the same time, according to the theory of heterogeneous polymerization, the original 40 ppi Cff cannot capture the particles. The particles grow up and are not decomposed and are captured by the second stage 20 Ppi Cff.

Therefore, two-stage can achieve deep purification.

Two or more filters

It is the superposition of multiple filtering effects of single filter plate, which is better than the filtering effect of single filter plate.

However, the filtration accuracy is limited. Although aluminum is a distribution-integration process when it passes through, it is conducive to alloying treatment. At the same time, heterophasic polymerization grows into metastable coarse particles, and the fluid diffuses and decomposes into particles. The 60ppi filter plate cannot be captured.

Sorry, the comment form is closed at this time.