22 8月 Southeast Asian aluminum market

Southeast Asian aluminum market

China Zhongwang completed the aluminum product manufacturer Alunna in Germany. Ge Wenda, chief financial officer of Zhongwang, pointed out that there are still projects under negotiation and will not be announced until the completion. It is also pointed out that Alunna is engaged in the production of seamless aluminum tubes used in aircraft, with an annual output of about 10,000 tons. In the future, the company will be at the financial level. Supported Alunna to assist the German company in expanding its plant and providing assistance in identifying new customers.

As for whether it will enter the commercial aircraft industry in the Mainland, become one of the suppliers of C919? Xu Jing, senior manager of corporate communications and investor relations, pointed out that the company is one of the members of the upstream and downstream cooperation mechanism of aluminum civil aircraft in the Mainland. Ge Wenda added that it is one of the general directions that the C919 will localize components. In addition to being paying attention to the aircraft component market, the company also intends to enter the yacht market and expects to break through in this area in the next 12 months.

Zhongwang itself is one of the component suppliers of the mainland high-speed rail “Revival”. Ge Wenda expects to start shipping the first two orders for the Renaissance this year, and the additional 500 train orders are believed to be shipped next year.

In the first half of this year, the mainland market accounted for 94% of Zhongwang’s revenue contribution, while the overseas market accounted for 6%. Ge Wenda pointed out that in recent years, the United States has a less friendly attitude towards aluminum products produced in the Mainland, so the company is expanding its markets in Europe and Southeast Asia.

When talking about the product portfolio, Ge Wenda pointed out that in the first half of this year, the company officially mass-produced aluminum formwork. The sales volume of the related products was 110,000 tons in the first half of the year. The unit price of the products reached RMB 32,000 per ton, and the gross profit margin reached 44%. With the increase in productivity and the lack of long holidays, the plant will be shut down in the second half of the year. In addition, Xu Jing pointed out that the company will be committed to maintaining a high dividend payout ratio, and the dividend payout ratio has been more than 35% since its listing.

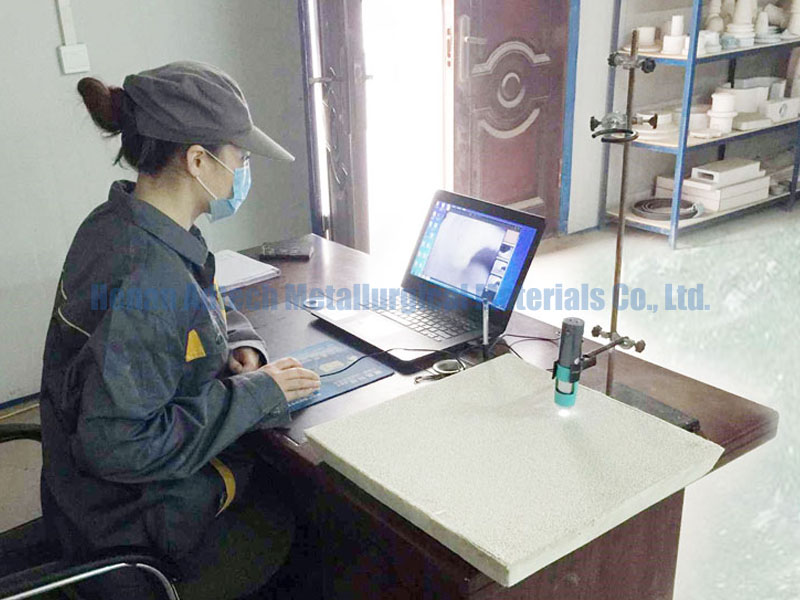

AdTech was established in 2012. At the end of 2013, the Chinese factory was put into production. AdTech is a pioneer in the pursuit of brand. It is focused on R&D and manufacturing of “on-line degassing filter equipment, Zirconia Molten Metal Filter,High Strength Ceramic Filter,Zirconia Ceramic Filte, hot top casting parts, cast nozzle plates, repair agents. After 5 years of wise and peer-to-peer, we have passed ISO 9001 quality system certification, ISO 14001 environmental assessment certification and SGS certification. The existing team has 168 people, including middle and senior titles. The company has 15 people. The company has developed dozens of series of products, and has covered all the products such as equipment, high temperature and filter materials required by the aluminum alloy foundry industry.

Sorry, the comment form is closed at this time.