al2o3 Ceramic Foam Filter

al2o3 Ceramic Foam Filter

AdTech al2o3 Ceramic Foam Filter is mainly used in aluminum and aluminum alloy for melt filtration.

It has high-efficiency filtration of slag, oxide scale, and non-metallic inclusions. and gate groove lining in aluminum solution to solve the sensitivity of aluminum and aluminum alloy to internal defects problems.

The unique production process and testing methods make the al2o3 Ceramic Foam Filter with a high opening ratio, uniform pore structure, and high surface strength. It can provide 7 inches to 26 inches and the highest mesh filter plate of 70ppi. AdTech is certified with ISO 9001 and ISO 14001 systems.

A special al2o3 Ceramic Foam Filter is a filter plate having two different pore sizes.

The expertise developed by Evans guarantees a perfect transition between two different apertures without the problem of closing or blocking the hole.

The composite combination range is large, and 30/50 PPI and 40/60 PPI are most often used. Other composite compositions can be manufactured as needed.

ADTECH keeps focusing on the manufacture of metallurgical materials

ADTECH is one pioneer following the International Enterprise, which keeps focusing on the manufacture of metallurgical material.

1. Ceramic Foam Filter

2. Degassing Unit

3. Filter Box

4. Hot-top casting series

5. Roll casting nozzle

6. Flux series

7. Other Metallurgical Material

AdTech has successfully developed high-flow filter plates to replace deep-bed filtration with filter plates, reducing costs and increasing productivity, solving the flexibility of casting various alloys, and making cleaning quick and easy.

The difference between the high-flow filter plate and the ordinary filter plate is that the high-flow filter plate has an opening ratio of 90%, and the ordinary filter plate has only 40%.

The same specification filter plate of the same specification, high-flow filter plate is three times the filtering capacity of the ordinary filter plate.

When using the high-flow filter, there is no need to replace the large-size filter plate and filter box, and still use the original size filter box, and only change the mesh number of the filter plate to obtain high-quality aluminum water.

The molten aluminum foam filter, also known as the foam ceramic filter plate, is composed of three types:

alumina ceramic foam filter, silicon carbide ceramic filter plate, and zirconia ceramic filter plate.

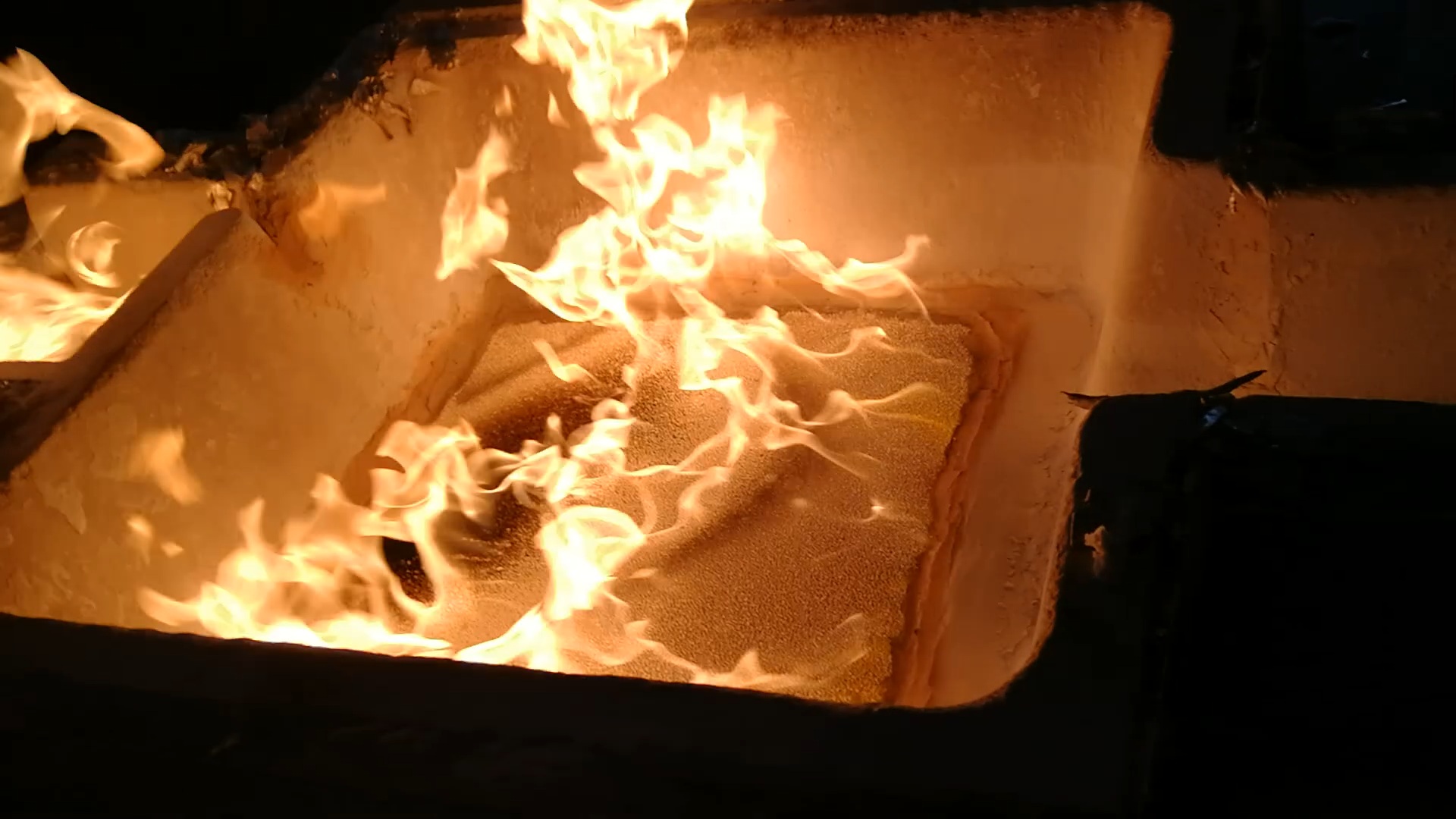

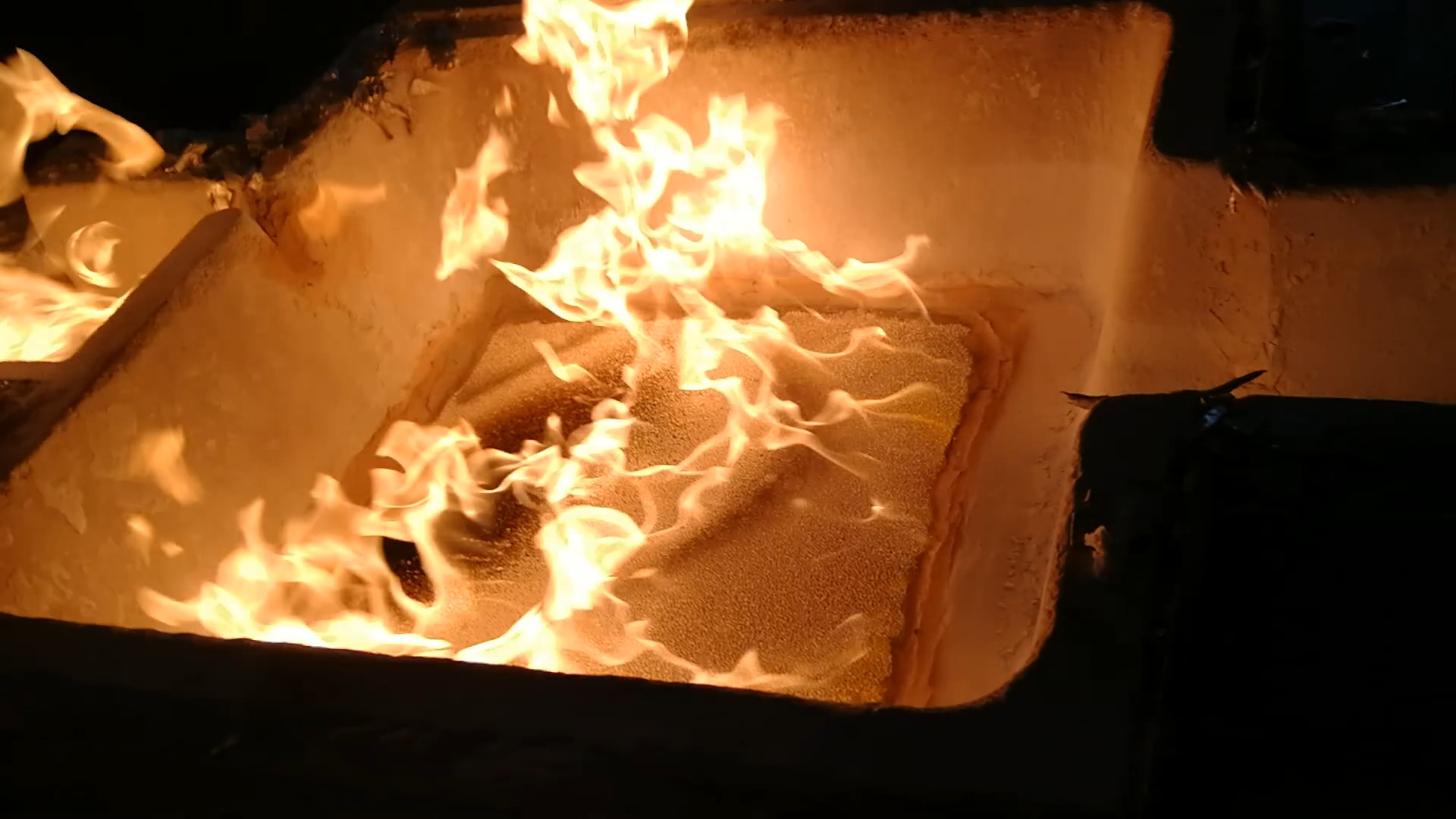

The folding process is a three-dimensional network structure and an organic foam sponge connected to the pores, which is invaded into a special ceramic slurry with thixotropic properties.

A special roll extrusion process is adopted to uniformly apply the ceramic slurry to the skeleton of the carrier, and then dried and solidified and then fired at a high temperature.

Thermal shock resistance refers to the resistance of alumina filter plates to damage caused by rapid temperature changes.

During the use of the alumina filter plate, we require the user to start the filtration before gradually heating the filter plate to the temperature of the filtered aluminum melt before use.

Since some users can’t follow this rule very well when using it, after the filter plate is placed, the melt is filtered without preheating, which requires the filter plate to have certain thermal shock resistance.

The better the thermal shock resistance, the more durable the filter plate and the better the quality.