Purification mechanism of foam ceramic filter

Purification mechanism of foam ceramic filter

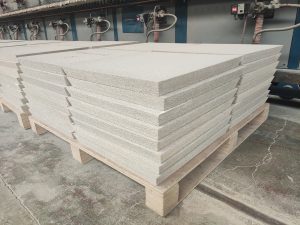

The foam ceramic filter can effectively intercept the inclusions in the liquid metal, and improve the casting quality and yield. Studying the purification mechanism of foam ceramic filters can provide a theoretical basis for the improvement and application of the filter.

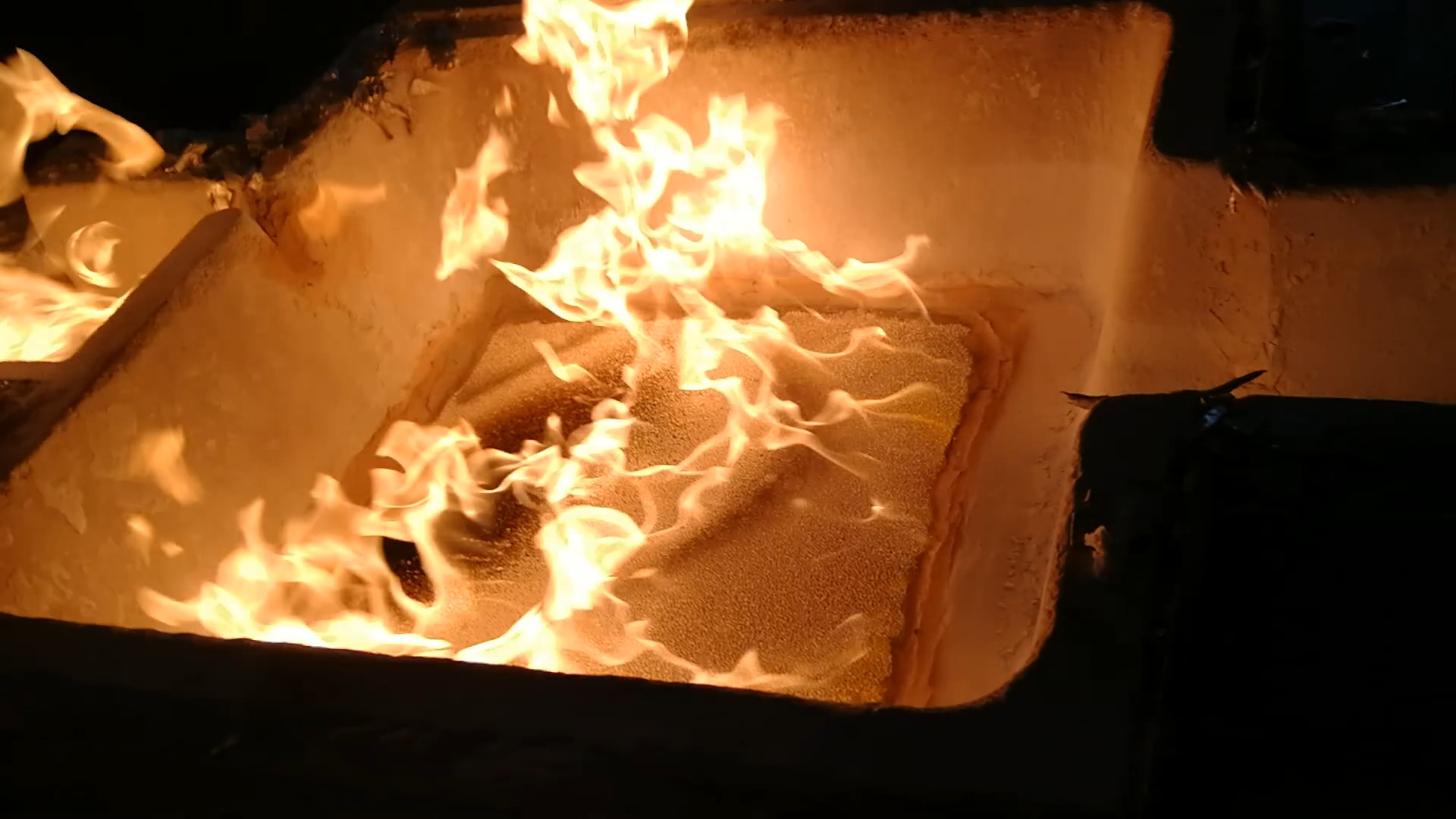

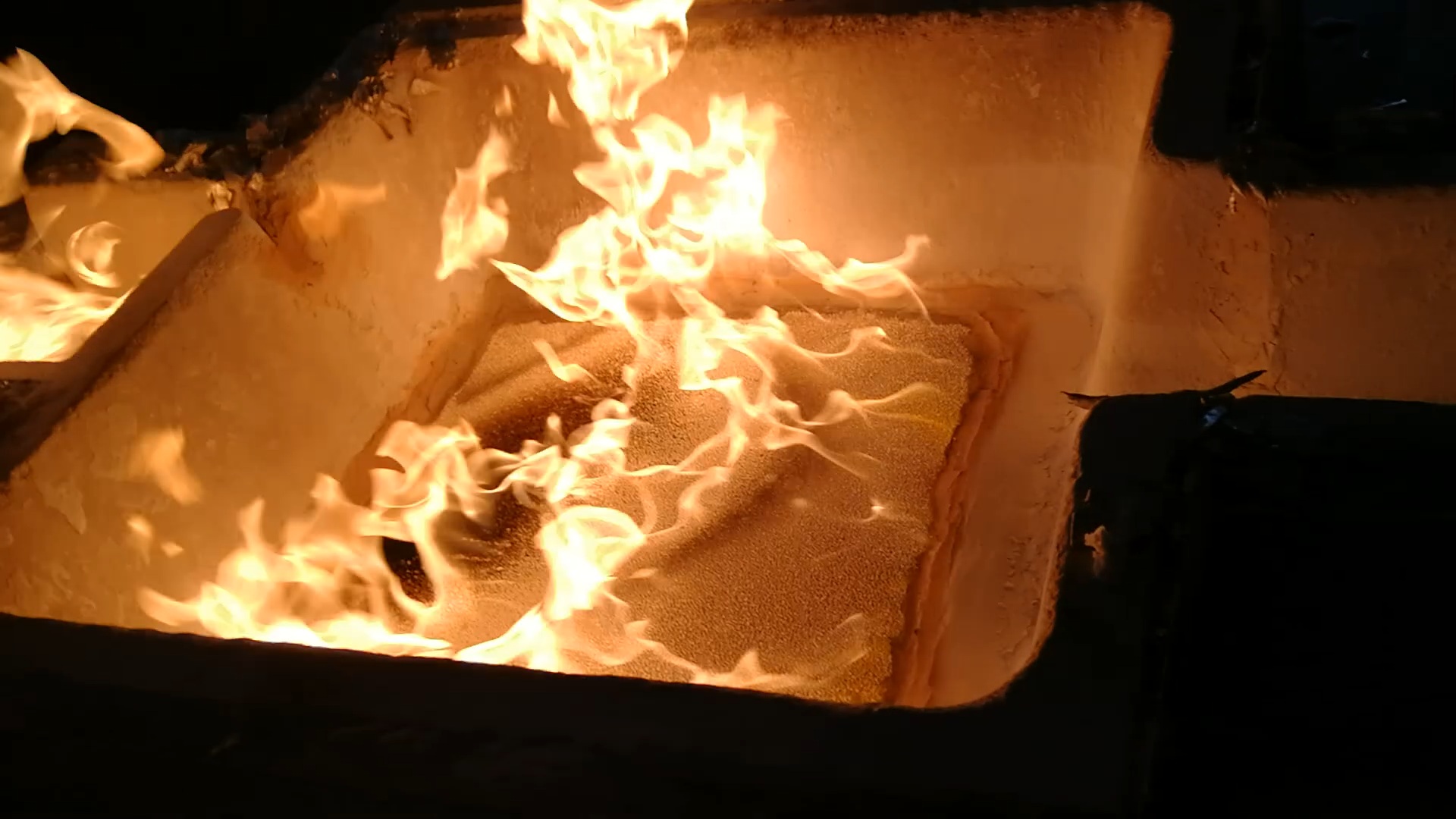

After the floating separation mechanism places the alumina ceramic foam filter, in the gating system, the metal flow resistance increases and the liquid metal is full in the gating system, so as to play the slag-blocking function of the gating system. At the same time, the liquid flow injected from the sprue is throttled through a filter, and the metal liquid briefly stays in the sprue. The low-density slag floats and separates, resulting in the same effect as the bottom pouring system. When the molten metal continues pouring through the foam ceramic filter, on the one hand, the slag with low density floats up, on the other hand, the vortex is effectively reduced or eliminated.

The “filter cake” mechanism foam ceramic filter is a zigzag channel that can efficiently mechanically block slag. Many inclusions larger than the filter holes are trapped at the filter inlet. As the number of captured inclusions increases, a “filter cake” composed of large inclusions is formed on the surface of the filter inlet end. The “filter cake” makes the fluid flow finer, so that inclusions smaller than the size of the filter mesh are also partially captured on the “filter cake”.

Purification mechanism of foam ceramic filter

The adsorption mechanism filter is placed in the transverse or inner runner of the mold cavity, and the filtration operation belongs to deep filtration. When the first stream of liquid reaches the surface of the filter inlet end, the adsorption between the liquid flow and the foam grid will occur, and at the same time, the “impact” phenomenon of the liquid flow will occur. The filter itself also has the function of blocking the flow. Under certain pressure, some impurity points are easy to be lubricated and absorb due to the close “coherent correspondence” relationship between inclusions and solid foam ceramic grids. This adsorption is mainly based on the physical adsorption of multiple molecular layers without selection, with inclusions adhering layer by layer on the filter mesh until they become blocked.