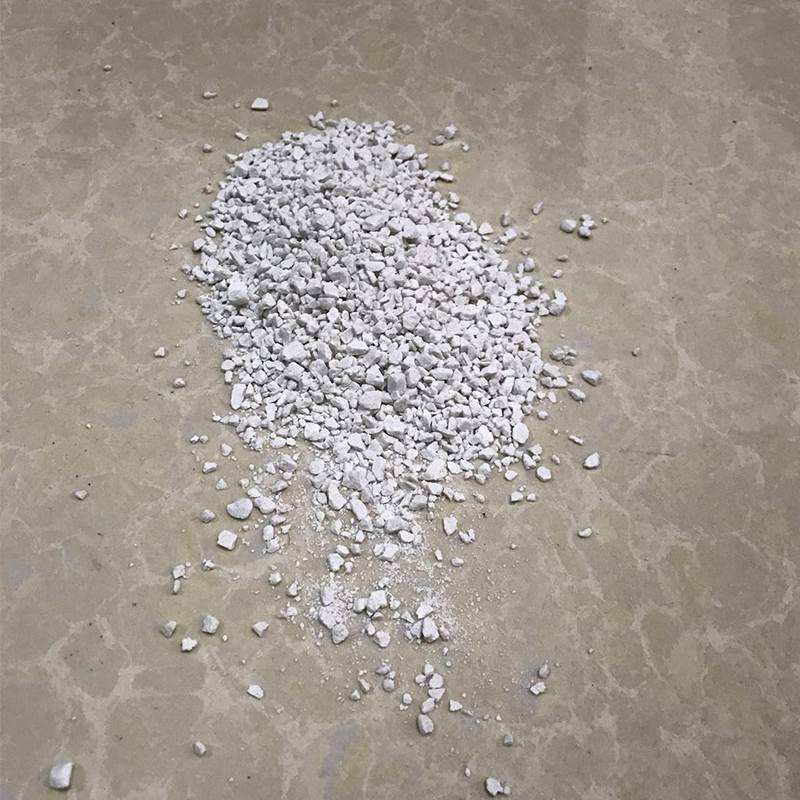

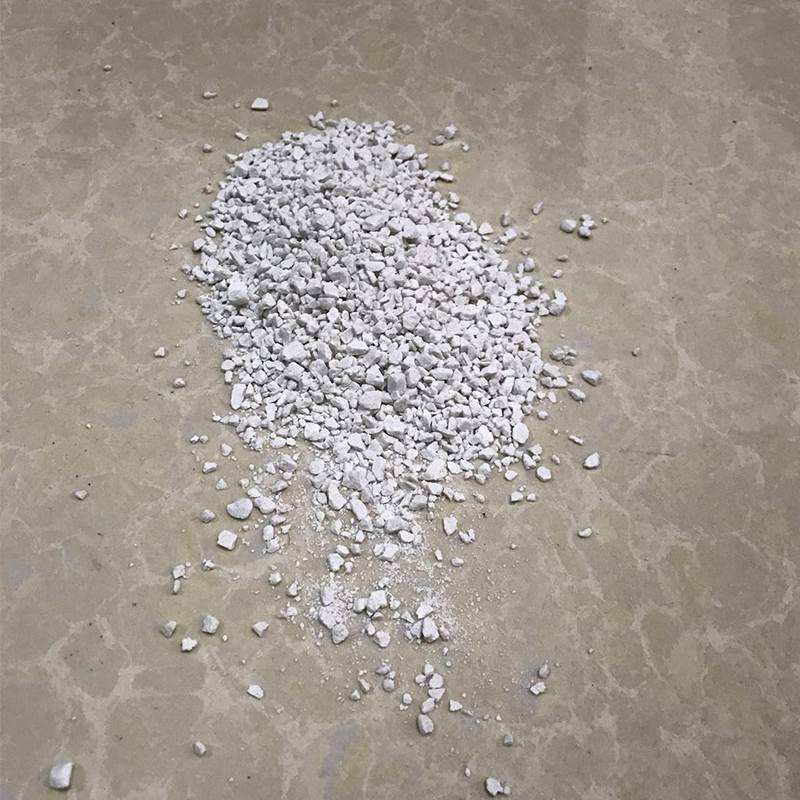

17 6月 Alu Granulated Flux

Alu Granulated Flux is used for slag removal of aluminum and aluminum alloys. Its main components are sodium chloride, potassium chloride and magnesium chloride. Chloride components account for more than 80%.

With optical density, it can be well dispersed on the surface of aluminum melt, but the flux containing chlorine salt only has limited ability to absorb and dissolve slag. This refining agent is smoke-free and non-toxic, reducing pollution in the aluminum casting workshop. Reduce the damage to workers’ bodies.

When the content of slag and gas in the melt of aluminum and aluminum alloy is too high, it will greatly increase the possibility of metallurgical defects such as pores and inclusions in the slab.

In turn, it will reduce the strength and plasticity of the material and affect the surface quality of the product.

When the sodium content in the aluminum alloy is too high, it is easy to form a liquid adsorption layer on the surface or grain boundaries of the dendrite during hot working, resulting in brittle fracture of the high-magnesium aluminum alloy.

Therefore, in the melting process of aluminum and aluminum alloys, slag, gas and alkali metals in the melt should be removed as much as possible. AdTech provides aluminum refining agent to remove slag.

Adding a small amount of fluoride salt to Alu Granulated Flux can improve the absorption and dissolution of flux to the slag, promote the separation of slag and aluminum liquid, and improve the refining effect.

A sodium-free refined preparation whose components are potassium fluoroaluminate, calcium fluoride, potassium carbonate, potassium sulfate, barium sulfate, potassium chloride and anhydrous aluminum chloride.

However, the density of barium sulfate is large (4.50g/cm3), and it is not easy to float out during use. Barium sulfate and calcium fluoride are also easy to bring impurity elements into the aluminum alloy melt.

In addition, most of the chloride salt components contained in Alu Granulated Flux easily absorb moisture in the air, and some chloride salts (such as magnesium chloride) usually exist in the form of crystalline hydrates.

If this part of water cannot be completely removed, when the flux enters the aluminum alloy melt, it will increase the hydrogen content in the aluminum alloy melt.

At present, most aluminum alloy fluxes are produced by simple mechanical mixing of various components. This method cannot completely remove moisture from the flux.

For aluminum alloy melts with strict control of gas content and alkali metal content, in addition to using nitrogen or argon as the refining gas, usually more active chlorine and hexachloroethane are also required for melt treatment.

Although chlorine and hexachloroethane have a good refining effect, they are hazardous to workers’ health, equipment and environment, and may be life-threatening in severe cases.

Adding Alu Granulated Flux to an aluminum smelter can improve the quality of castings. They are mixed for specific processes and applications. Flux helps protect surfaces, treat scum, clean furnace walls, clean metals, hydrogenate and refine crystals.

Sorry, the comment form is closed at this time.