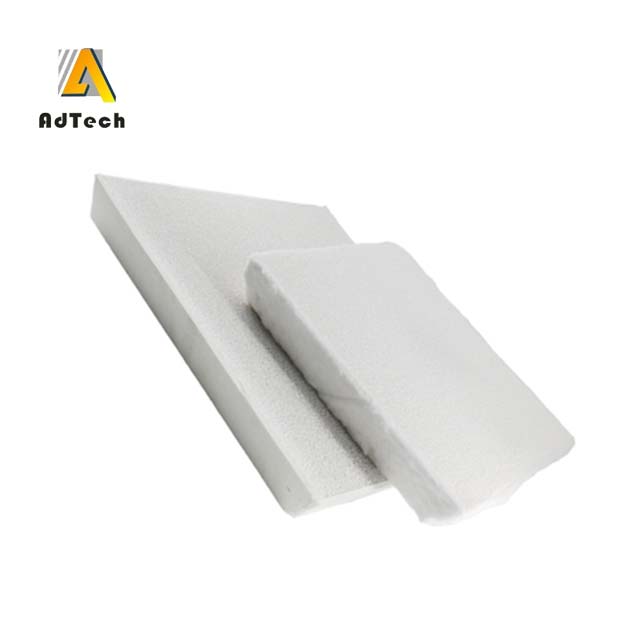

29 10月 Alumina Carbide Ceramic Foam Filter

Alumina Carbide Ceramic Foam Filter

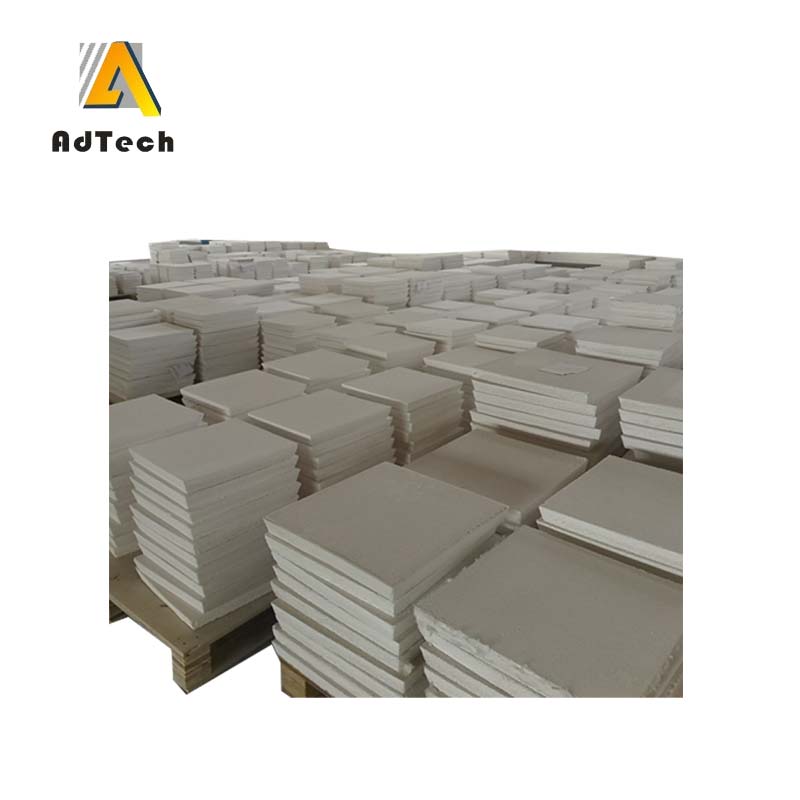

Melting at 700-750 °C, using a multi-stage degassing purification system to degas the melt, using 30ppi foam ceramic filter plate to filter the melt.

The aluminum alloy ingot is obtained by melt casting, and the stress relief treatment is carried out at 300-500 ° C for ≥ 1 hour.

The sawn aluminum alloy sheet is controlled to a temperature of 350-500 ° C for a period of ≥ 0.5 hours for solution treatment, and the tensile deformation is controlled to be 1% to 4%, and the temperature of the aluminum alloy sheet is controlled at 50 to 300 ° C for 2 to 40 hours. The aging treatment was carried out in an hour to obtain an aluminum alloy plate.

Compared with the aluminum alloy plate prepared by conventional hot rolling method, the aluminum alloy plate has fewer preparation steps, shorter production cycle, lower cost, better plate quality, high strength, meets the needs of the market, and has good economic benefits. Social benefits.

Sorry, the comment form is closed at this time.