02 3月 Alumina Ceramic Porcelain Rod Control Pin

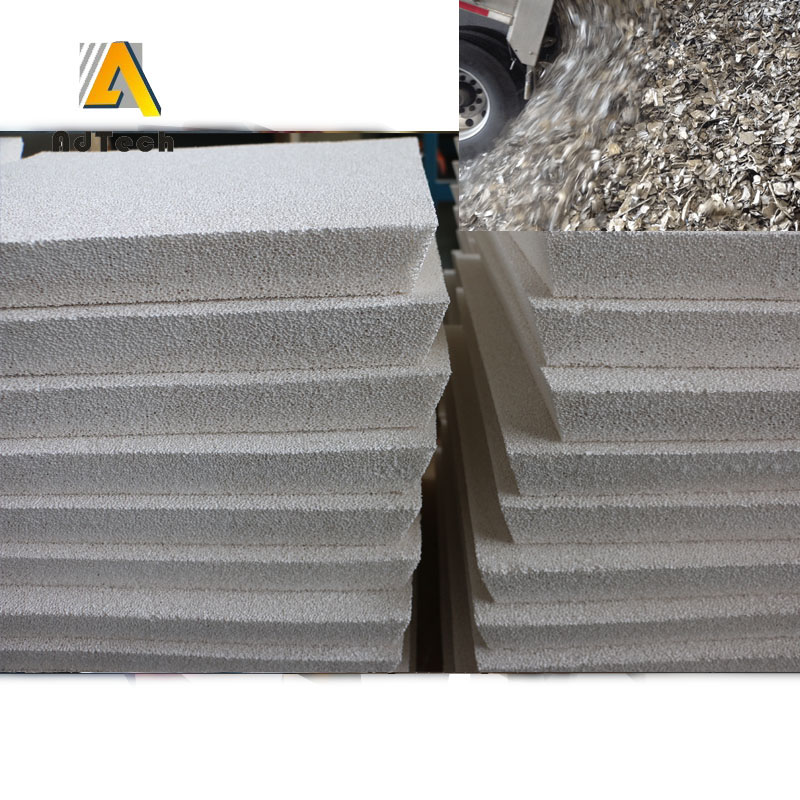

Alumina Ceramic Porcelain Rod Control Pin

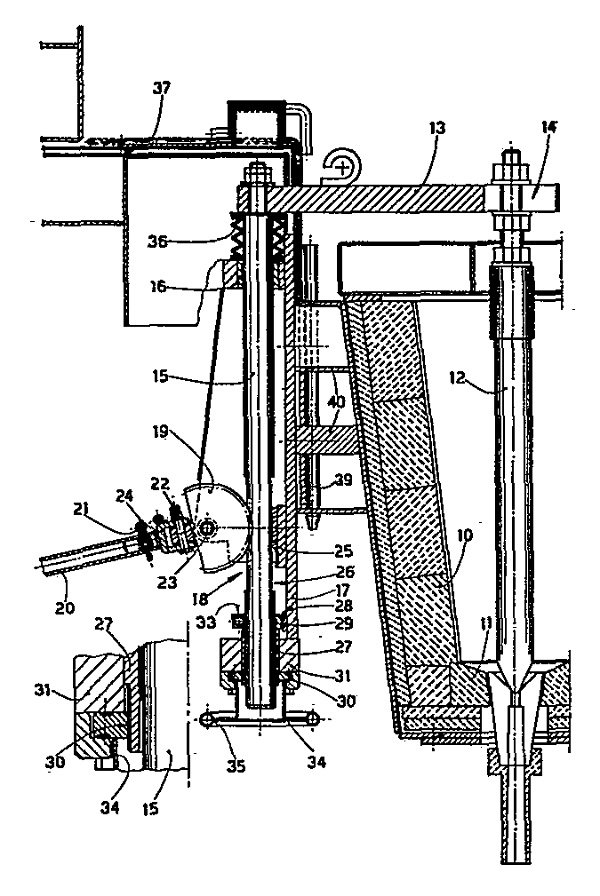

Control pins. are generally made of a refractory material, which is able to withstand the high temperature of the molten metal. The material must also be hard so as to resin wear on the end of the rod, where it presses against the seat in the spout.

One of the most commonly used materials is dense fused silica (DF’S). This material is quite tough and has good thermal shock characteristics, but silica is wetted and attacked by liquid aluminium and control pins made of this material therefore have to be provided with. a non-stick protective coating, for example of boron nitride.

This coating has to be reapplied frequently (for example every one or two pouring operations) and such pins therefore have a high maintenance requirement.

Further, although DFS iS quite tough, it is susceptible to cracking and these cracks tend to propagate through the material during use.

This can eventually cause part of the control pin to break away and block the pouring spout. As a precaution against this, a stainless steel wire is sometimes embedded in the DFS material to ensure that even if the control pin breaks, the broken part can still be withdrawn from the spout.

Another disadvantage with control pins made of DFS is that they tend to have a high heat capacity and have to be pre-heated prior to commencement of the metal pouring operation, to bring them up to or close to the temperature of the molten metal.

This adds considerably to the complexity of the pouring operation and gives rise to the risk S-P550762c.wpd 7 October 2004 of a serious accident when transfernng the hot control pin from the pre-heating oven to the spout.

If the control pin is not pre-heated, the molten metal can solidify upon contact with the control pin thus blocking the spout.

No Comments