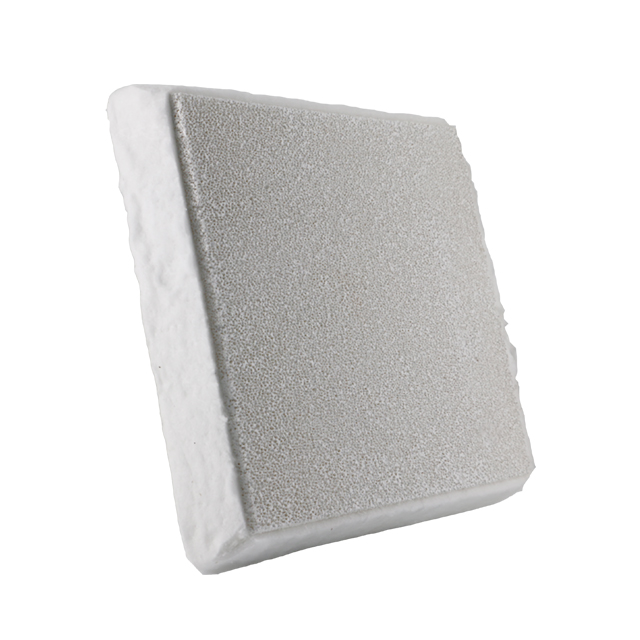

08 10月 Alumina Foam Filter

Alumina Foam Filter

The metal flow passes through a system of branched channels. Small particles that did not linger on the filter surface, as they turned out to be too small, continue to move along with the metal flow inside the network of filter channels.

During filtration, the Alumina Foam Filter channels gradually overgrow, retaining small particles of inclusions. Thanks to this, it is possible to clean the metal from fine particles of impurities contained in the melt. This is of great importance since even the smallest inclusions found in alloy wheels, blanks for making foils or building profiles preclude their further use.

In addition, it was noted that when passing through the ceramic foam filter, the content of gas dissolved in the metal decreases, which also positively affects the further properties of the metal.

Alumina Foam Filter – Designed specifically for filtering aluminum at temperatures up to 1150ºС

zirconia-based ceramic foam filter for filtering steel at temperatures up to 1700ºС

Depending on the mass of the filtered metal and the required filtration rate,

filter porosity at the request of the customer can be from 10 to 60 ppi (pores per inch).

The standard range of filters allows you to install them both horizontally and vertically. The shape of the filters can be either rectangular or round.

The quality of the Alumina Foam Filter is ensured by constant monitoring by a special quality department. Each batch of filters is tested for differential pressure, mass accuracy, and a test protocol can be provided at the request of the customer.

Our representatives will provide you with technical assistance in choosing filters for your operating conditions for maximum effect.

Filters are made on the basis of Al2O3 and are intended for filtering melts at temperatures not exceeding 1150С. Filters have a uniform pore structure and high surface hardness, ensuring the absence of “dusting” of the filter and excellent chemical stability to many chemical elements present, in particular, in alloys of the 8xxx group.

According to their geometric characteristics, Adtech filters can be manufactured both in standard sizes accepted in the metallurgical industry (from 7 to 23 inches, see tables at the end of the catalog), as well as in any other shapes and sizes ordered by the client. The sealing gasket can be thermally expandable from a special foaming material or from ordinary refractory wool.

The porosity of ceramic foam filters, traditionally measured at the number of pores per square inch – PPI, can vary from 10 to 60. Filters have a high level of open surface porosity, controlled for each filter both directly – visually and indirectly – by measuring the pressure drop behind the filter.

In addition to the above filter options, it is possible to supply duplex filters Duplex-Filter, which consist of two layers with different porosity, which allows you to replace a sequential system (two filters located next to each other with different porosity). Despite the slight difference in price compared to a standard filter, a duplex filter provides better filtering quality and a number of other practical advantages.

Sorry, the comment form is closed at this time.