08 6月 Aluminium Alloys Filtration

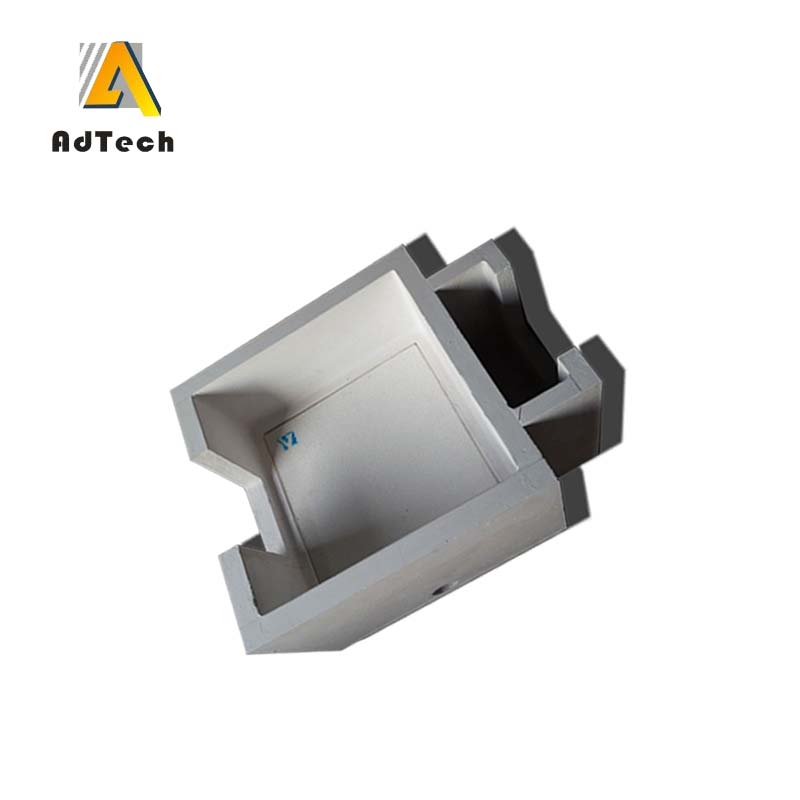

Aluminium Alloys Filtration is used for the filtration of molten aluminum and non ferrous alloy.

Alumina Foundry Foam Filters mainly for filtration of aluminum and alloys in foundries and cast houses .With the excellent resistance to attack and corrosion from molten aluminum, the filter can effectively remove inclusions, reduce trapped gas.

Aluminum alloys are divided into deformed aluminum alloys and cast aluminum alloys according to their uses.

Deformed aluminum alloys include daily-used aluminum alloy doors and windows, and space shuttle body materials, which can be heat-treated and not heat-treated according to different usage requirements.

The other type is cast aluminum alloys, which mainly include aluminum-silicon alloys, aluminum-copper alloys, aluminum-magnesium alloys, aluminum-zinc alloys, and aluminum rare earth alloys.

In the actual production process, cast aluminum alloys are classified according to the content of various chemical elements.

The smelting process needs to add or reduce the amount of raw materials according to the actual chemical composition. The finished aluminum ingots supplied by some manufacturers already contain various alloy elements required by the product. The smelting process basically does not need to add other chemical elements, and does not need to be directly mixed. Smelting into aluminum liquid, there is no order of addition, this type of aluminum alloy is suitable for products with a single structure.

The pure aluminum ingot is used as the raw material, and the chemical composition is adjusted according to the actual production needs. The advantage is that aluminum alloy liquids of different brands can be smelted, which can meet the needs of different products, and the product types are diverse.

Before smelting the aluminum alloy, the ingredients are blended according to the requirements. According to the alloy grade, the ingredients need to consider the burning loss of the smelting process of various elements in new materials, recycled materials, and intermediate alloys.

The more economical and commonly used smelting method in aluminum alloy smelting is gas furnace melting, which requires fast melting, short time, and less air intake.

The order of feeding not only affects the melting efficiency and alloy consumption, but also directly affects the quality of the molten aluminum.

The principle of feeding is: first small and then large, easy to melt first and then hard to melt, firstly burn less, then easy to burn, and finally deteriorate.

First add small pieces of regrind, alloy additives with lower melting point (such as Al-Si alloy), then aluminum ingots and intermediate alloys with large volume and high melting point (such as Al-Mn), Mg and other elements that are easy to burn Join last.

The small pieces of regrind are first put in the bottom of the furnace to protect the furnace body and reduce the impact on the furnace wall when the large pieces of regrind are charged, and because the melting point of the regrind is low and easy to melt, the melting efficiency can be improved for subsequent melting of raw materials with higher melting points. Lower the temperature and add Mg to reduce the burning loss.

Some domestic vehicle supporting enterprises adopt this method when smelting aluminum alloys: first preheat the melting furnace, start feeding after reaching the predetermined temperature, first add small pieces to the bottom of the furnace material, and then add large aluminum ingots. After the burned elements are added, they are directly pressed into the molten aluminum to melt.

Aluminium Alloys Filtration improves the quality of aluminum wheel castings, avoids defects such as slag inclusions, air holes, and improves ductility.

Melting is a process in which a solid heats up and becomes a fluid liquid. After the feeding is completed, melting starts. During the smelting process, it is necessary to ensure that the melting is fast and uniform, and the temperature near the flame is high, reaching more than 1200 ℃. In order to avoid local overheating and excessive temperature, the aluminum alloy oxidation will cause serious inconvenience to the later product refining. Stirring should be carried out, and the unmelted furnace charge should be squeezed into the aluminum liquid, so that almost all of it is immersed in the stirring to avoid local overheating. For the final immersion of Mg and other elements, the flame cannot be directly heated and melted, and because the aluminum liquid is immersed in the raw material, the temperature is reduced, and the Mg and other elements are melted at a relatively low temperature, which reduces the burning loss and improves the combustion efficiency.

The aluminum alloy begins to melt at about 600 ℃, and it will melt when heated to 660 ℃. The melting temperature should not exceed 760 ℃. When the melting temperature exceeds 770 ℃, the aluminum alloy is seriously oxidized, hydrogen absorption and slag inclusion increase during the melting process, and coarse grains appear during the casting and solidification process, which reduces the mechanical properties. In order to reduce the oxidation of the aluminum alloy during the melting process, 0.4% to 0.5% of the covering agent is added during the melting process to protect the aluminum oxide film from being damaged. The type of covering agent is similar to the chemical composition of the slag cleaning agent.

The temperature of the smelting process is controlled at 720 ~ 760 ℃. After the aluminum ingot is melted, raw materials with higher melting points such as Si element and Ti agent are added. Ti forms heterogeneous crystal nuclei in the alloy, which plays a role in refining the structure and pressing it into Melt in aluminum liquid to reduce burning loss. After the aluminum ingot is basically melted, alloy elements such as Mg and Cu, which are easily burned, are added. It cannot be added too early to reduce the burning loss, nor too late, which affects the diffusion and causes segregation. Close the furnace door and continue smelting.

After smelting is complete, there are a lot of scum on the surface of the aluminum alloy, mainly Al2O3 and other oxide inclusions. These fine inclusions are heavier than the aluminum liquid, but after aggregation and agglomeration, the specific gravity is lighter and floats on the surface. Slag removal is required. The dosage of slag removing agent is added according to 0.2%~0.5%, evenly sprinkle on the surface of the aluminum liquid, and perform shallow uniform stirring. Put the slag on the furnace door, close the door and let it stand, on the one hand, the slag cleaning agent has a heating effect, which can melt the aluminum liquid adhering to the scum; on the other hand, it can effectively separate the slag from the aluminum liquid, which is beneficial to the slag Aluminum slag, after standing for a few minutes, smoothly remove the aluminum slag from the furnace door. Aluminum alloy smelting is a very complicated process. Due to the inconsistent burning loss of different elements, after the slag is stripped, the aluminum liquid needs to be sampled for physical and chemical analysis to ensure that each element can only be discharged into the transfer range within the qualified range. Ladle degassing and refining, otherwise it needs to be properly adjusted.

Sorry, the comment form is closed at this time.