18 6月 ALuminium Castertip

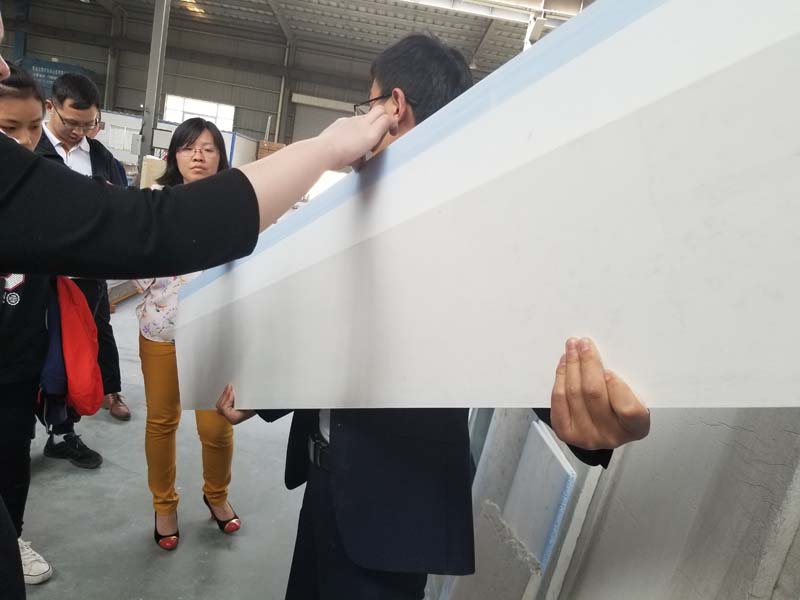

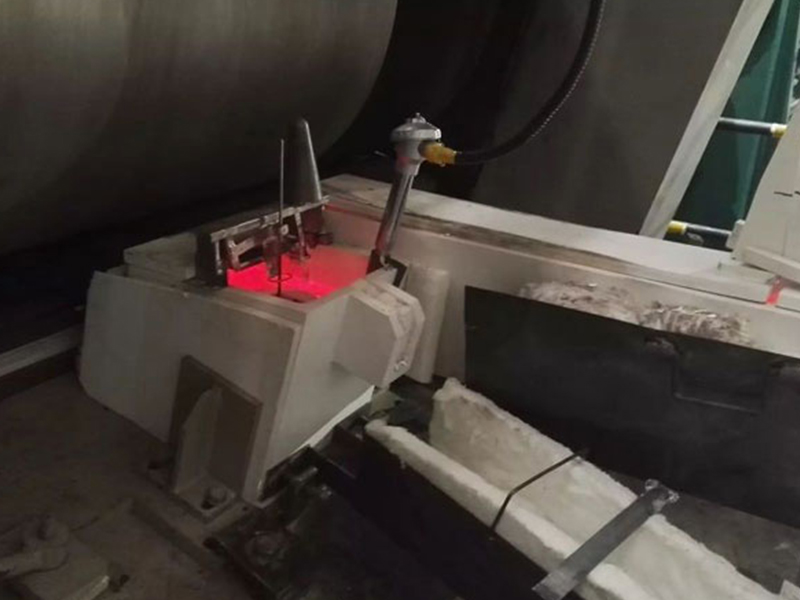

ALuminium Castertip is a key component on the aluminum strip continuous casting and rolling mill, and its quality directly affects the quality of the strip and the production yield.

ALuminium Castertip special process can effectively prevent the molten aluminum from eroding the casting nozzle and avoid carbonization.

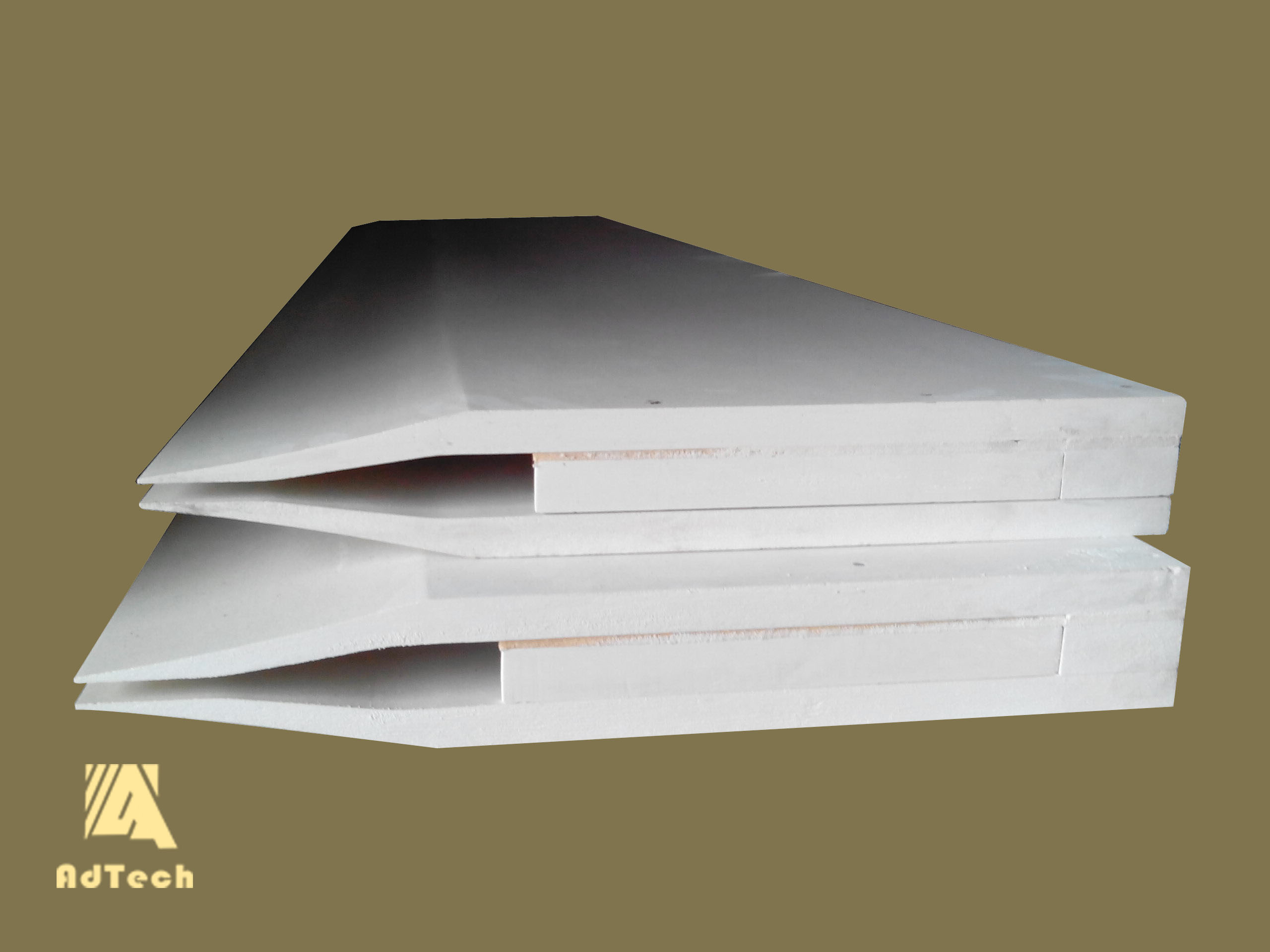

The fracture structure is a fine and uniform layered fiber structure to prevent the existence of flake tissue.

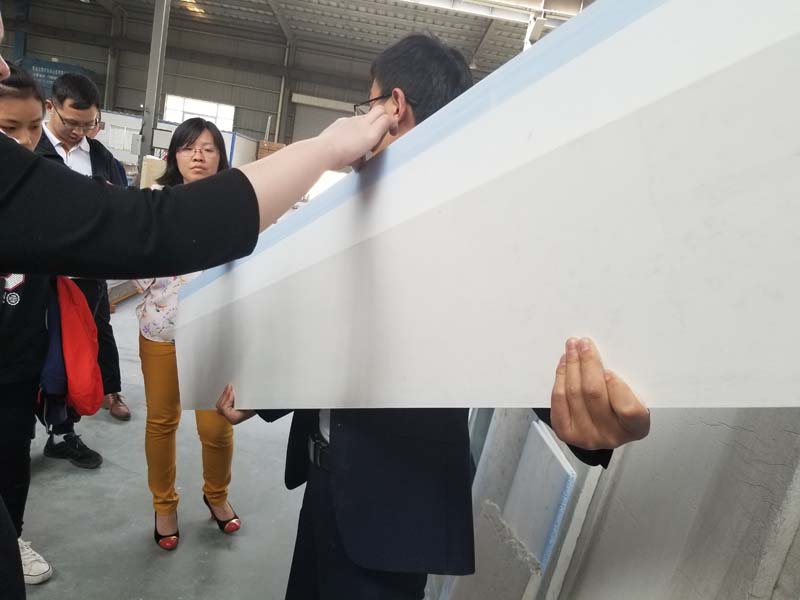

The coating on the working surface is even and smooth to prevent the occurrence of cracks and falling off of the coating, which provides a guarantee for high-quality cast plates.

The surface is specially treated with aluminum titanate coating, and its special process can effectively prevent the aluminum liquid from eroding the casting nozzle and avoid carbonization.

The fracture structure is a fine and uniform layered fiber structure to prevent the existence of flake tissue.

The coating on the working surface is even and smooth to prevent the occurrence of cracks and falling off of the coating, which provides a guarantee for high-quality cast plates.

According to customer requirements, we can produce various types of casting nozzles and supply methods.

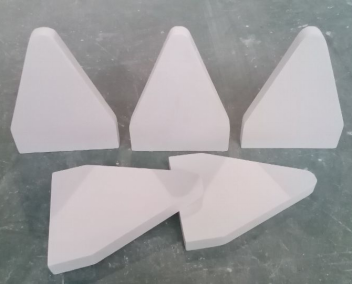

The casting nozzle diverting part is a high-strength fiber casting nozzle produced with specific refractory additives. This product has tough texture, high compressive strength, excellent high temperature resistance and excellent support.

It can be used as an excellent refractory for industrial fire kiln temperature range fire insulation.

The nozzle diversion component is made of ceramic fiber cotton as raw material and vacuum formed. Its strength is higher than that of fiber blanket and vacuum forming felt. It is suitable for application fields that have rigid strength requirements for products.

In addition, according to the application requirements, there is a higher bulk density of vacuum formed ceramic fiber board products, the heat insulation performance, wear resistance and strength of the board have been further improved.

A small amount of organic binder is included in the formulation of the nozzle diverting part to enhance its cold strength, and the organic matter can be burned down when it is first burned at about 200°C to 300°C.

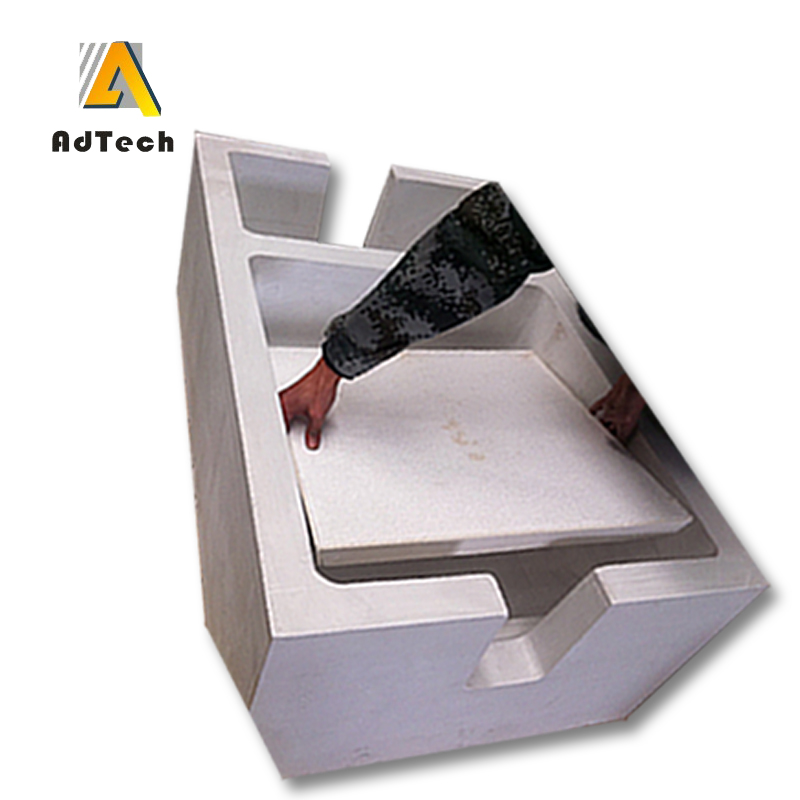

ALuminium Castertip includes a nozzle upper fan, a nozzle lower fan, a left side plate, a right side plate, a bottom plate and a shunt component, which together form a flat box-shaped nozzle structure.

The shunt component includes a plurality of wedge-shaped shunt blocks, the tip of the wedge-shaped shunt block faces the front end of the nozzle structure, and the plurality of wedge-shaped shunt blocks are arranged at intervals along the width direction of the nozzle. Including the left cross plate I, the right cross plate I and the middle plate I, a gap is set between the right end of the left cross plate I and the left end of the middle plate I as the melt channel I, and the right end of the right cross plate I to the right side plate is In the closed section, a gap is provided between the right end of the right horizontal plate I and the right end of the intermediate plate I as the melt channel II.

The utility model has a novel structure. By setting a multi-stage shunt structure, it can effectively ensure that the melt flows evenly in the nozzle cavity, ensure that the flow rate and temperature of the molten metal at the front edge of the nozzle are uniform, and avoid excessive temperature difference in different areas at the front of the nozzle. In this way, the crystal structure of the slab is uniform and consistent, and high-quality products are produced.

In the production of Castertip diverting parts, the casting nozzle of the casting and rolling mill is an important component. The aluminum alloy is input into the channel of the roll gap from the front box of the casting and rolling mill, and the design of the structure of the casting nozzle (commonly known as casting nozzle) of the aluminum alloy casting and rolling mill It directly affects the uniformity of the lateral quality distribution of the cast plate, so that local defects such as local hot strips, cold lines and holes in the cast strip are likely to occur during the production process, which affects the deep processing performance of the feedstock and even directly causes the scrap of the product.

The structure of the casting nozzle of the casting and rolling mill should meet: the aluminum alloy melt passes the front box with a reasonable streamline (laminar flow), no dead zone (no turbulence); the melt is evenly distributed over the entire length of the roll gap; the melt flows into the roll gap The temperature must be uniform.

Sorry, the comment form is closed at this time.