21 3月 Aluminium Degassing

Aluminium Degassing

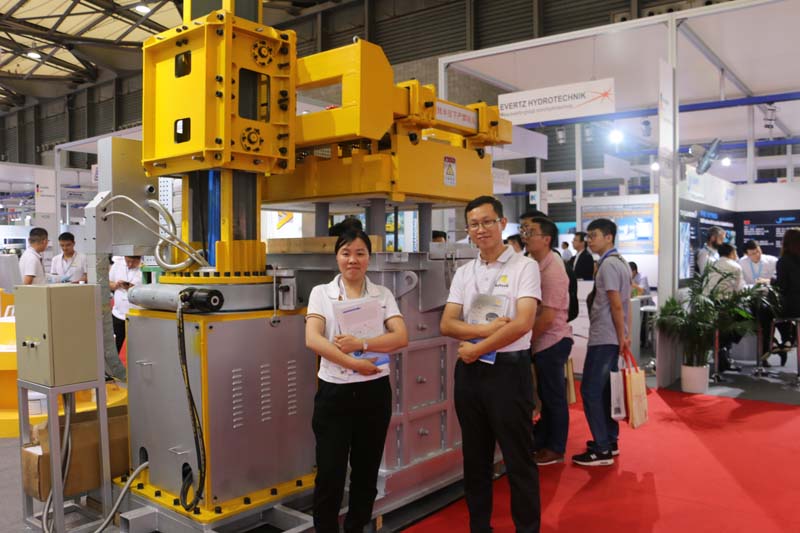

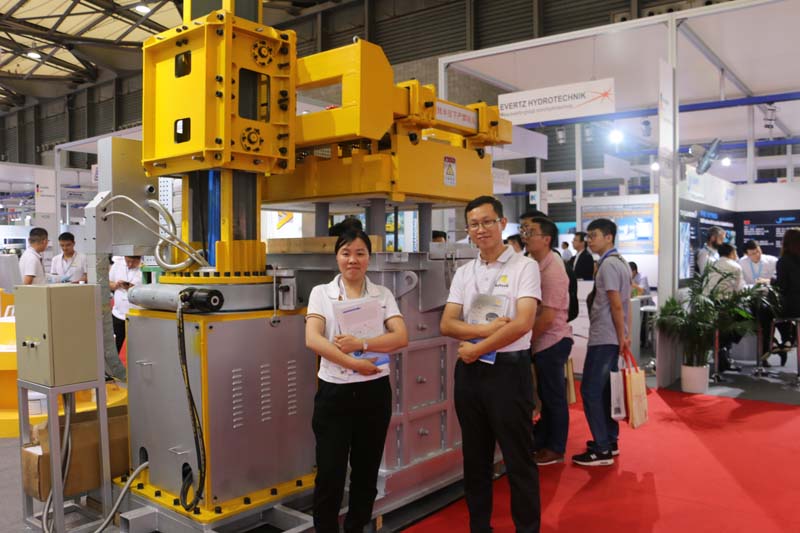

AdTech Online Aluminium Degassing Machine is installed between the furnace and the casting machine to remove hydrogen and other residues from the molten Aluminium Degassing and its alloys that affect its quality and mechanical properties.

In Aluminium Degassing control, metal casting must complete two things

1. Prevent and minimize the introduction of hydrogen in the melt.

2. Pre-casting hydrogen. The Aluminium Degassing will focus on measurement and removal, usually introduced into the melt by a rotary degasser.

When the purge gas bubbles are introduced into the melt, they collect hydrogen as they float on the surface.

The best case is that these hydrogen-saturated bubbles leave the melt and reduce the hydrogen content.

In this case, from a thermodynamic point of view, the process efficiency is 100%, but as the gas content in the melt decreases, the equilibrium pressure of hydrogen in the bubble also decreases, so the purge gas required to remove residual hydrogen The amount must increase.

Aluminium Degassing Performance:

1. The aluminum water online degasser mainly processes the molten aluminum liquid containing a certain amount of hydrogen and other residues (alkali metal, slag inclusion), and is removed after being treated by the degassing equipment.

2. The principle of treatment is gas flotation.

The aluminum degassing machine has the characteristics of saving energy and lowering the ambient temperature, heating and rapid temperature control in real time, long service life, simple maintenance, large adjustable power range, practical and reliable.

The aluminum alloy flawless holding furnace is designed in the form of flawless structure. The molten pool is made of imported high-quality pouring and grouting. It is non-stick aluminum and does not hang slag. It is directly heated by electric energy, clean and environmentally friendly. It is faster than indirect transmission heating and saves electricity. The heating furnace cover is pneumatically opened and closed.

Clean slag maintenance, temperature control, temperature accuracy, aluminum liquid thermocouple protection using silicon nitride material, no iron, long life, safe and reliable, with overheat protection, overload protection and over-temperature protection, fully protect equipment and operation Safety.

The principle of the device is that the rotor rotating in the work breaks the inert gas (argon or nitrogen) blown into the aluminum water into a large amount of dispersed bubbles and disperses it in the aluminum liquid; the bubble is in the melt by the gas partial pressure difference And surface adsorption

The principle is to absorb the hydrogen in the melt, adsorb the oxidized slag, and take it out of the surface of the melt as the bubble rises, so that the melt can be purified; because the bubbles are finely dispersed, uniformly mix with the rotating melt, and then rotate with a spiral Slow shape

When it comes up, it does not form a continuous airflow when it comes into contact with the melt, which significantly improves the purification effect. Both argon and nitrogen can be used as a degassing solution for aluminum. The purity of the inert gas must be above 99.95%.

No Comments