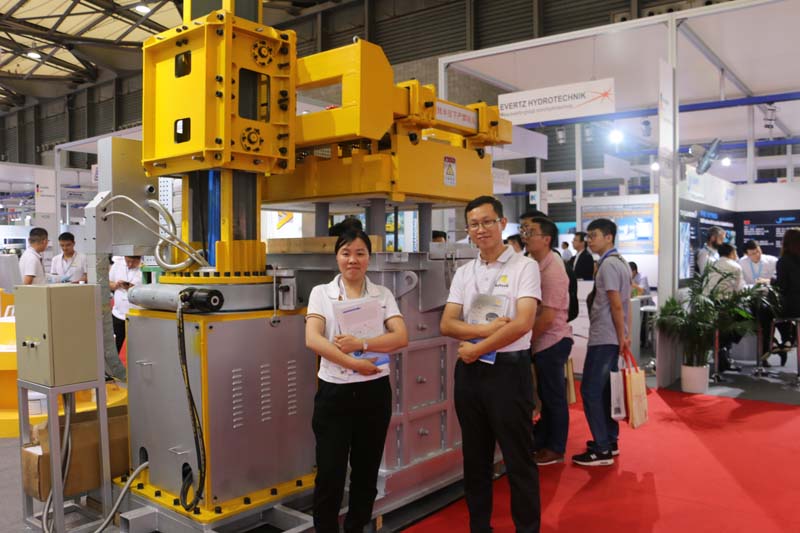

14 10月 Aluminium Degassing Equipment

Aluminium Degassing Equipment brings a major breakthrough in automated, efficient, and cost-effective degassing. The principle of these machines requires the rotor to be able to generate very small inert gas bubbles, which are evenly and uniformly distributed throughout the molten metal pool.

Aluminum foundries have long recognized the need for effective flux gas treatment to remove hydrogen and inclusions. Therefore, the recent development is to meet this requirement and achieve the best degassing efficiency.

Aluminium Degassing Equipment removes these undesirable components by bubbling gas, usually nitrogen, through molten metal.

The gas is usually introduced through a degassing rotor, which reduces the size of the bubbles and disperses the nitrogen gas throughout the molten metal bath.

As the generated bubbles rise through the molten metal mass, they absorb the hydrogen dissolved in the metal and remove it from the melt.

In addition, the non-metallic solid particles are swept to the surface by the flotation effect of bubbles, and then can be removed by skimming the metal.

Aluminium Degassing Equipment uses silicon nitride as the degassing rotor. The degassing rotor adopts a two-part assembly form with independent shaft and rotor head.

As the geometry of the rotor head decreases, the efficiency of hydrogen removal will decrease over time.

Eventually, the efficiency of the rotor head is reduced, the shaft becomes thinner to the point of fracture, and the rotor assembly must be replaced.

Considering this failure mechanism, compared with existing foundries, the efficiency of the rotating degassing process should be improved by improving the material and rotor head design to extend the life of the rotor and maintain its performance.

Aluminium Degassing Equipment is the best choice for molten aluminum purification and degassing in the aluminum alloy industry.

According to Rusal process engineers, molten aluminum is extremely reactive, so when it comes in contact with humid air or wet tools, the water will decompose and release hydrogen in the melt. Adtech China is negotiating the relevant project progress of the Online Degassing Unit and Ceramic foam filter unit through sales@adtechamm.com with Rusal Aluminium.

Excessive dissolved gas will have a detrimental effect on the mechanical properties of the final aluminum casting. Anyone who makes castings knows that dissolved gases have an important effect on the distribution and number of pores and shrinkage. The level of dissolved hydrogen must be controlled to minimize waste. In order to control the gas in aluminum, the metal caster must accomplish two things:

1. Prevent and reduce hydrogen from entering the melt.

2. Measure and remove hydrogen before pouring.

Sorry, the comment form is closed at this time.