24 7月 Top five aluminium extrusion companies in the world

Top five aluminium extrusion companies in the world

Top five aluminium extrusion companies in the world

Aluminium extrusion is one of the most popular forms of aluminium products. Extruded aluminium products are being used worldwide every day in innovative application areas. The possibilities for using aluminium profiles have no bounds. They are used for their strength, flexibility, durability and sustainability in several end-user sectors such as construction, transportation,

electrical, machinery and consumer durables. They are 100% recyclable and the processing is easy and emits little hazardous gasses.

ADTECH is one pioneer followed by the International Enterprise, which keeps focusing on the manufacture of metallurgical.

material.

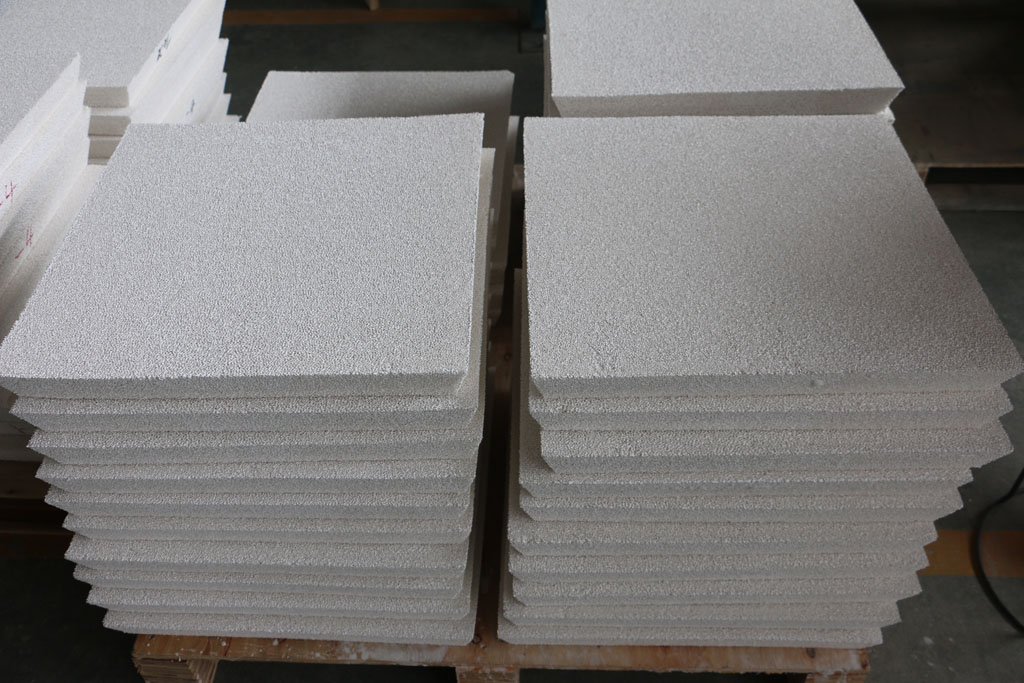

1. Ceramic Foam Filter

2. Degassing Unit

3. Filter Box

4. Hot-top casting series

5. Roll casting nozzle

6. Flux series

7. Other Metallurgical Material

Aluminium extrusion is replacing steel in the transport and construction sector mostly for its lightweight and corrosion resistance quality along with infinite recyclability. The building and construction segment is the biggest market for aluminium extrusion.

About 65% of the aluminium content in construction is estimated to be recycled annually. Its usage in building and construction is expected to increase in doors, windows, panels, windows frames, ladders, and bridges in the near term.

Here is a list of the top five leading aluminium extrusion manufacturers in the world. The list is based on sales volumes and industry coverage and is dynamic depending on changing market conditions.

Sapa Extrusion

Currently, Sapa is the world leader in aluminium solutions – a new company that has merged the aluminium extrusion businesses of Sapa and Hydro. Together, the companies account for the largest share of the aluminium extrusion market. Sapa produces extruded aluminium profiles, semi-finished components, system solutions and finished products according to customer’s requirements. Sapa’s extruded aluminium profiles are used as components in virtually all available end-use applications including buildings, cars, industries, machines etc. With the help of their global reach and local presence in extrusion, building systems and precision tubing, Sapa has been able to achieve a net sales turnover of NOK 55 billion in 2015. The company has 23,000 employees in more than 40 countries and headquarters in Oslo.

China Zhongwang Holdings Limited

China Zhongwang Holdings Limited, together with its subsidiaries, is the second-largest industrial aluminium extrusion product developer and manufacturer in the world and the largest in Asia. The Group’s main focus has been the light-weight development in the transportation, machinery and equipment and electric power engineering sectors through the provision of quality processed

aluminium products. As per the annual report of the company, revenue from the Group’s aluminium extrusion business amounted to approximately RMB15,392,441,000 for 2015. The total sales volume of the Group’s aluminium extrusion business was 750,049 tons for the period.

After more than 20 years of dedicated development, the Group currently has over 90 internationally advanced aluminium extrusion production lines (including 21 production lines of large-scale aluminium extrusion presses of 75MN or above) with an aggregate annual production capacity of close to 2 million tonnes. In addition, the Group has installed two ultra-large 225MN extrusion

presses, which are the largest and most advanced presses in the world.

China Zhongwang announced the acquisition of Aleris Corp. U.S. for $2.3 billion in September 2016. The deal gives the owner of Asia’s largest producer of extruded aluminium smooth access to American and European technology, as well as the market which is dominated by high-profile buyers Boeing Co. and automakers such as Audi.

Arconic

Arconic, the value-added business of the original Alcoa has led the way in innovative extrusion technology. Building design solutions like Kawneer, Reynobond or Reynolux are all based on Arconic’s aluminium application and make windows and doors, curtain wall systems, railings, shutters and conservatories from Arconic extruded products.

Arconic holds the number one position in the North American building and construction architectural framing market and a strong position in Europe. They are also the market leader in aluminium curtain walls and front entry systems. Alcoa also manufactures extrusions for their Latin American customers for use in trains, buildings and a diverse range of industrial applications.

Constellium

Constellium is a leading manufacturer of advanced and highly specialized aluminium extrusion products, solutions and services.

The company offers a complete range of customized aluminium extrusions, tubes and bars in soft and hard alloys, and large structural extrusions, complemented by ready-to-use profile-based solutions for selected applications. Constellium not only supplies the products but also supports its customers with downstream technology and service activities, including machining and surface treatment, R&D and technical support.

The company caters to automotive, transport, industrial, energy and building markets. Constellium’s extrusions are produced at 8 production facilities located in the Czech Republic, France, Germany, Slovakia and Switzerland.

Hindalco-Novelis

Hindalco is a leading aluminium extrusion manufacturer in India. The company manufactures a wide range of alloy billets, including hard and special alloys for extrusion. Hindalco has two plants for aluminium extrusions at Renukoot and Alupuram in India with well-established manufacturing processes and QA systems. The in-house casting unit at the plant comprises seven extrusion presses and state-of-the-art technology for conducting testing of various parameters such as hardness, tensile strength, conductivity, ultrasonic and caustic etching.

The extrusions are manufactured from high-quality billets, made from virgin in-house metal. They find application in various industries such as architecture, electrical, industrial, transport, defence and consumer durables.

For more than 100 years, aluminium building materials have been essential for building everything from the most dazzling public edifices to the most practical residential buildings. Novelis, a Hindalco subsidiary provides a variety of specialized aluminium extruded products designed to meet the exacting requirements of the building and construction industry including Aluminium Building Facades, Aluminium Gutter and Roof Windows, Sunbreakers, Compound Tubes etc.

Novelis is one of the world’s leading producers of aluminium bottles and cartridges. To manufacture these products, Novelis uses a process called impact extrusion and employs forward, backward and combined extrusion processes.

Other prominent vendors in the extrusion market include Gulf Extrusions Co. (LLC), TALCO, Zahit, Balexco, Qatar Aluminium Extrusion Company and Bonnell Aluminum.

Established in 1976, Gulf Extrusions Co is the flagship company of a dynamic multi-industry conglomerate – Al Ghurair Group with over 37 years of experience in Aluminium Extrusion. The company was founded to meet the increasing demand for Aluminium Extrusions in domestic, regional and international markets for architectural, industrial and automotive sectors.

Bonnell Aluminum has been one of North America’s leading manufacturers of custom aluminium extrusions since 1955. Bonnell Aluminium manufactures custom aluminium extrusions in a variety of alloys and sizes up to 16 inches wide. We also offer a variety of finishes and coatings, including paint, and anodize. Our services include thermally broken and fabricated extrusions.

The aluminium extrusion market is highly fragmented as it is operated by many small and medium-size suppliers along with a handful of large manufacturers. We have tried to list the leading five aluminium extrusion companies in the world. It is to be noted that with the increasing number of new suppliers entering the market, the market share for these top manufacturers is dropping. Several companies are merging for better sales realization and the market dynamics keep changing. The growth potential for aluminium extrusion is huge and more and more companies are venturing into the segment to leverage upon the opportunities.

No Comments