12 6月 Aluminium Multi-Function Refining Flux

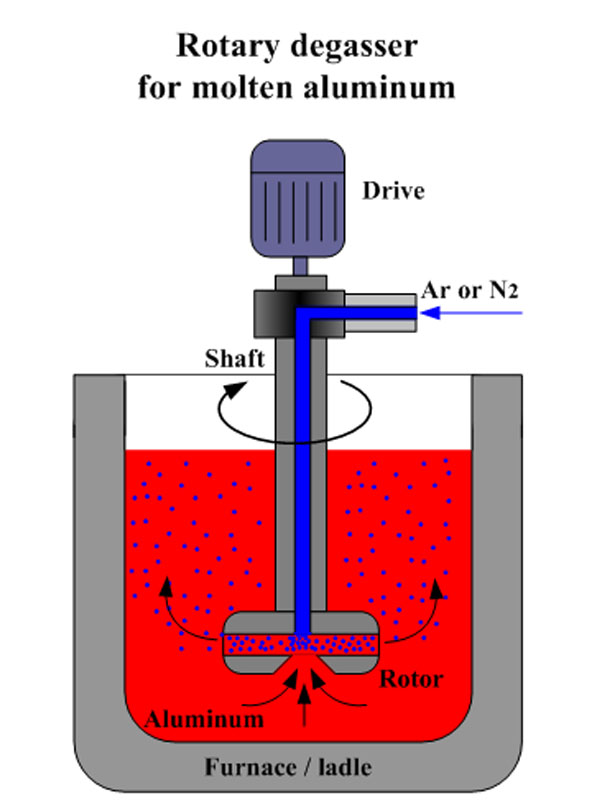

Aluminium Multi-Function Refining Flux uses high-purity inert gas (nitrogen or argon) as a carrier to spray this product evenly into the aluminum melt pool.

It can be automatically spread on the surface of the aluminum liquid to form a continuous covering layer.

During use, it can continue to play the functions of heat insulation, gas isolation, refining, degassing and slag removal.

It can absorb and dissolve the inclusions in the melt, and can remove the gas from the melt. It will not cause flux to contain slag, and no harmful gas will be produced.

Range of use

It is used for various deformation and casting aluminum alloys with high purity requirements.

Features

1. It has the dual functions of removing impurities and degassing, improving the internal quality and mechanical properties of the product.

2. It can avoid the formation of new oxides and oxide films during the process.

3. When refining, purifying and degassing, the flux generates less heat, which reduces the burning loss of aluminum and alloy components.

4. The slag aluminum has good separability and spreadability, and also has a certain effect of slag cleaning, covering and modification.

5. Powder, the slag is loose and dry after treatment, easy to remove, and the slag contains less aluminum.

6. The liquid aluminum has good quality, which can improve the gloss of the product surface;

7. It does not contain toxic and pungent substances such as hexachloroethane, and it is a non-toxic, non-hazardous and environmentally friendly product.

Instructions

Put a certain amount of Aluminium Multi-Function Refining Flux into the storage tank of the injection device, cover it with nitrogen first, then open the switch under the refining tank, and insert the seamless steel pipe into the aluminum when the refining seamless steel pipe is sprayed with flux For horizontal movement in the liquid, the end of the steel pipe should be inserted at a depth of about 20 cm from the bottom of the furnace (do not touch the furnace wall and the bottom of the furnace to prevent pipe blockage), move forward, backward, left and right, and spray the quantitative flux evenly and continue to spray evenly. Blow for a week, then draw the steel pipe from the aluminum liquid, and then turn off the nitrogen.

Process parameters

1. Processing temperature: 660~720 degrees Celsius.

2. Recommended dosage: 0.2~0.5% (can be selected according to quality requirements)

Precautions

1. Adjust the powder sprayer valve to control the speed of powder feeding. The principle is that powder is sprayed during the refining time.

2. Control the height of the aluminum liquid tumbling by controlling the nitrogen, the principle is that the tumbling height is better under the premise of not blocking the tube, it is better to control it below 15cm.

Sorry, the comment form is closed at this time.