18 6月 ALuminium Nozzle Cavity

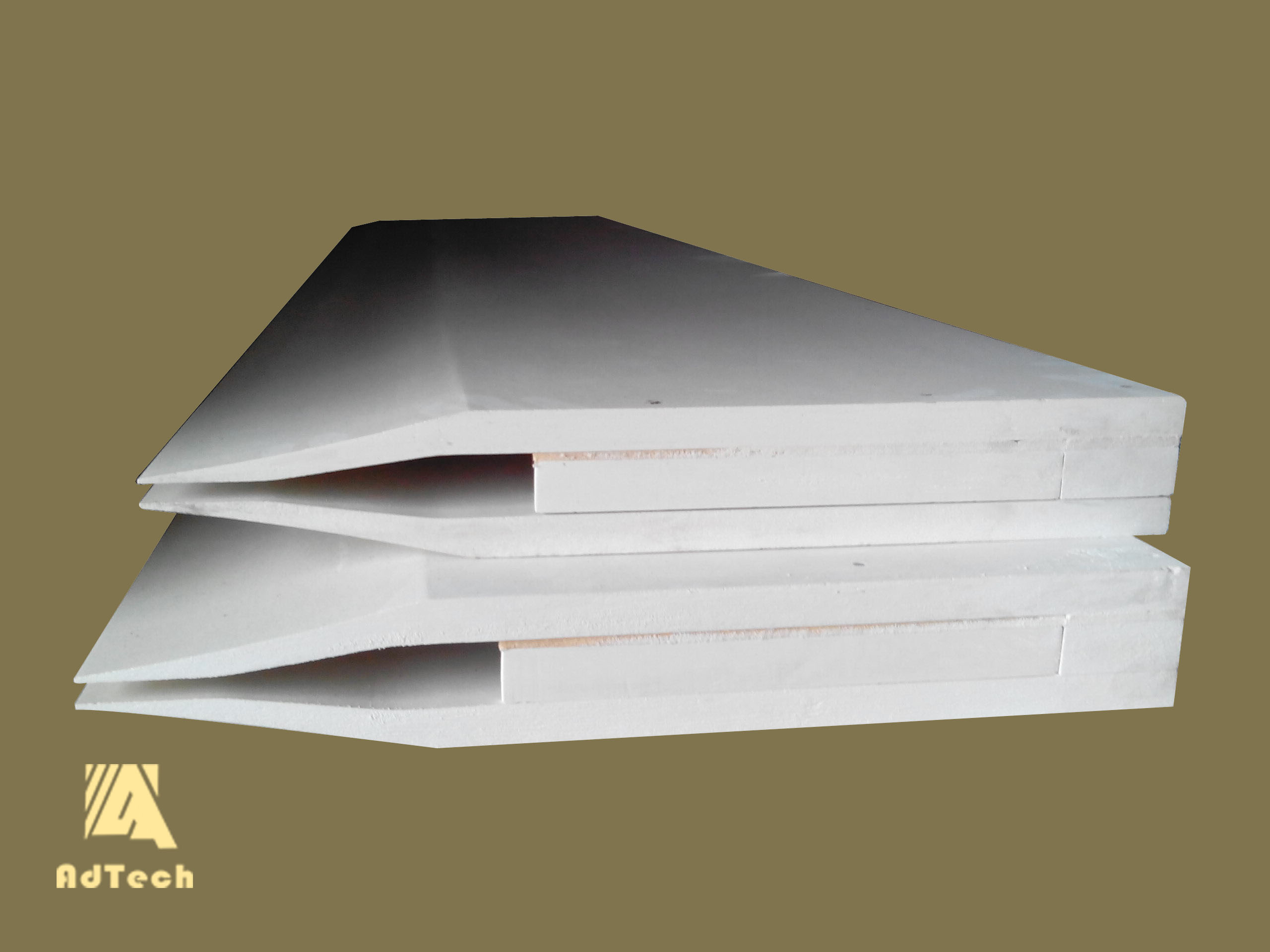

ALuminium Nozzle Cavity is made of ceramic fiber and other materials. It has the advantages of good elasticity, no deformation, and long use time.

Its special process can effectively prevent the aluminum liquid from eroding the casting nozzle and avoid carbonization.

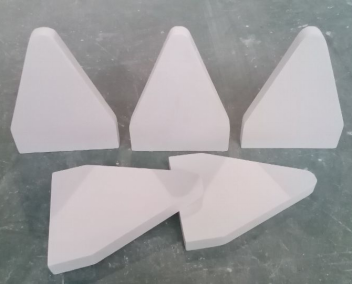

The fracture structure is a fine and uniform layered fiber structure to prevent the existence of flake tissue.

The coating on the working surface is even and smooth to prevent the occurrence of cracks and falling off of the coating, which provides a guarantee for high-quality cast plates.

ALuminium Nozzle Cavity is made of ceramic fiber and other materials. It has the advantages of good elasticity, no deformation, and long use time.

Its special process can effectively prevent the aluminum liquid from eroding the casting nozzle and avoid carbonization.

The fracture structure is a fine and uniform layered fiber structure to prevent the existence of flake tissue.

The coating on the working surface is even and smooth to prevent the occurrence of granular cracks and coating shedding, which provides a guarantee for high-quality cast plates.

The high-aluminum casting nozzle materials produced by AdTech are all calcined at high temperature, do not contain organic matter, and have a shrinkage rate of 800°C of zero.

The high-aluminum casting nozzle material is a soft casting nozzle made of ceramic fiber without slag balls, which is used for the production of aluminum plates and aluminum foils.

The hard casting nozzle made of ceramic fiber without slag ball and imported filler has the characteristics of high strength, smooth surface and wear resistance, and is suitable for casting and rolling of high-speed aluminum sheet.

All use high-quality materials (without sodium silicate), with good non-stick aluminum, low thermal conductivity, good high-temperature stability, uniform density, smooth surface and precise dimensions, and the product quality reaches the international advanced level.

The surface of ALuminium Nozzle Cavity is specially treated with aluminum titanate coating, and its special process can effectively prevent the aluminum liquid from eroding the casting nozzle and avoid carbonization.

The fracture structure is a fine and uniform layered fiber structure to prevent the existence of flake tissue.

The coating on the working surface is even and smooth to prevent the occurrence of cracks and falling off of the coating, which provides a guarantee for high-quality cast plates.

According to customer requirements, we can produce various types of casting nozzles and supply methods.

Sorry, the comment form is closed at this time.