12 Jun Aluminium Refining Flux

Aluminium Refining Flux for wheels is used for refining and degassing the melt in the smelting process of automobile wheels.

Use parameters

1. Refining temperature: 700~730℃

2. Refining time: 8~15 minutes

3. Dosage 2~5kg/T aluminum

Instructions

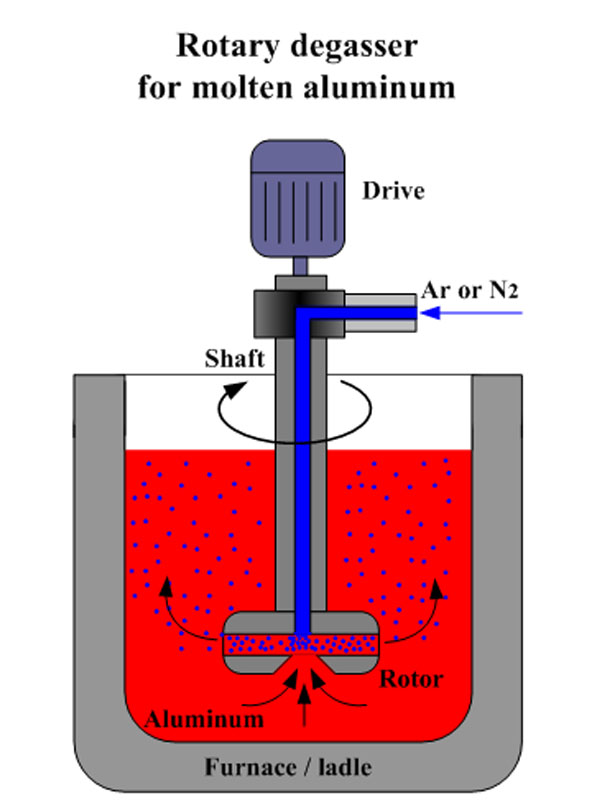

Add the required amount of refining agent to the inside of the refining tank and cover it. Turn on the switch of the refining tank and pass nitrogen gas. When the refining agent is sprayed from the refining iron pipe, it can be inserted into the furnace and moved slowly and evenly throughout the furnace 2 to 3 times, when the powder in the tank is completely sprayed, first draw the refining tube from the aluminum liquid, and then turn off the nitrogen.

Features

This product is a cylindrical body made of sodium-free salts at a certain ratio. This flux reacts in the melt to release a variety of gases. The melt is refined, degassed, and slag removed to improve the strontium phosphorus modification effect .

Aluminium Refining Flux for piston is used for refining and degassing the melt during the smelting process.

Use parameters

1. Refining temperature: 700~730℃

2. Refining time: 8~15 minutes

3. Dosage 2~5kg/T aluminum

Instructions

Add the required amount of refining agent to the inside of the refining tank and cover it. Turn on the switch of the refining tank and pass nitrogen gas. When the refining agent is sprayed from the refining iron pipe, it can be inserted into the furnace and moved slowly and evenly throughout the furnace 2 to 3 times, when the powder in the tank is completely sprayed, first draw the refining tube from the aluminum liquid, and then turn off the nitrogen.

advantage

This product is a cylindrical body made of sodium-free salts at a certain ratio. This flux reacts in the melt to release a variety of gases. The melt is refined, degassed, and slag removed to improve the strontium phosphorus modification effect .

Sorry, the comment form is closed at this time.