16 5月 Aluminum Casting Ceramic Filter

Aluminum Casting Ceramic Filter

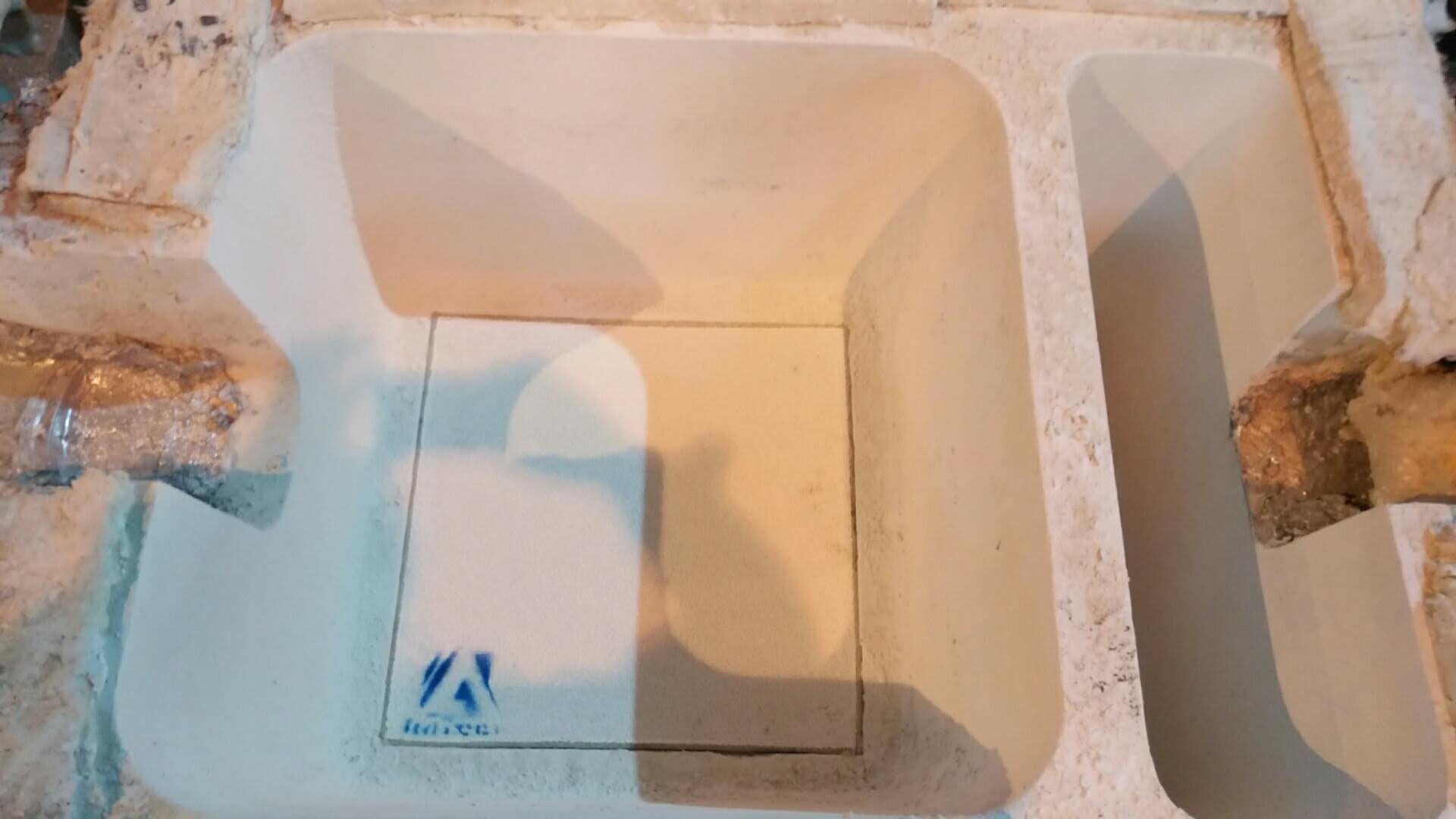

Aluminum Casting Ceramic Filter use good portiforium foam and high purity ceramic as raw material, can removes non-metal solid mixture from molten aluminium and aluminium alloy fusant effectively in your aluminium casting industry.

Our ceramic foam filter use good portiforium foam and high purity ceramic as raw material, can removes non-metal solid mixture from molten aluminium and aluminium alloy fusant effectively in your aluminium casting industry.

Aluminum Casting Ceramic Filter Advantages

even aperture, high porosity, proper sinter, high strength of anti-flexing and anti-compression, effective filtering.

Aluminum Casting Ceramic Filter Function

It is widely applied to the aluminium fusant filter equipment of continuous casting, half-continuous casting, gravity casting, and low pressure casting.

Alumina ceramic foam filters are different from aperture specifications from 20 to 50ppi, with different sizes and shapes.

Chemial composition: Al2O3 is more than 85%, SiO2 is less than 15%.

Types of ceramic foam filter are conditioned in particular by requirements for their application. Filters for filtration of nonferrous metal alloys (casting temperature up to 1000 °C), filters for filtering cast iron with flaky and spheroidal graphite and filters intended for steel filtration are therefore used in practice. Depending on the cast material, Al2O3, SiC, ZrO2 or graphite based filters are applied.

There are several methods used to make Ceramic Filter For Casting.

The polymeric-sponge method, which will be described in more detail here, produces open-cell structures by impregnating a polymeric sponge with a ceramic slurry, which is then burned out to leave a porous ceramic.

The direct foaming method can produce both open-cell and closed-cell structures, with the foam structure more common.

In this method, a chemical mixture containing the desired ceramic component and organic materials is treated to evolve a gas.

Bubbles are then produced in the material, causing it to foam.

The resulting porous ceramic material is then dried and fired. For the honeycomb or cellular structure, a plastic-forming method called extrusion is used, where a mixture of ceramic powder plus additives is forced through a shaped die (like play dough). The cellular structure can also be produced using a pressing method.

Sorry, the comment form is closed at this time.