18 7月 Aluminum Casting Filtration

Aluminum Casting Filtration

Aluminum Casting Filtration is very important for the quality control of aluminum ingots.

Remove primary and secondary liquid/solid non-metallic inclusions in the metal melt, simplify the casting system, prevent inclusion defects, improve the mechanical properties of the casting, reduce the machining allowance of the casting, improve the surface finish of the casting, and extend the life of the machining tool. .

The main inclusions of the castings are: slag containing calcium carbonate and iron, manganese, aluminum oxide, unmelted inoculant particles, sulfide, magnesium silicate, residual solvent, sand, and the like.

Aluminum Casting Filtration Purification Mechanism

Regarding the research on the mechanism of aluminium filtration and purification, there are mainly the following viewpoints, deep bed filtration mechanism, floating separation mechanism, adsorption mechanism and rectification mechanism.

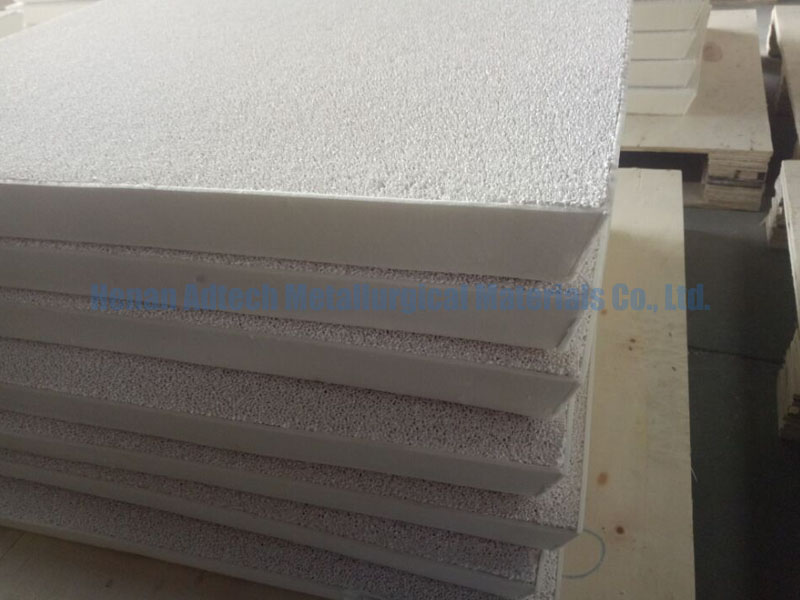

Deep Bed Aluminum Casting Filtration Mechanism

Inside the foam ceramic filter, the path through which the melt flows is meandering, and in a small local area

To the phenomenon of cross-flow reentry, this mainly serves two purposes.

1. Can greatly increase the probability of inclusion particles in contact with the filter;

2. The flow rate and flow direction of the melt are changed faster, so that the fine inclusions in the melt are trapped and left behind at a certain point to be arrested.

Adsorption mechanism

The filter is placed in the runner or the sprue of the cavity, and when the first liquid flow reaches the surface of the inlet end of the aluminium casting filter during pouring, the adsorption of the liquid flow and the foam grid occurs.

This adsorption is mainly based on the physical adsorption of the unselected multi-molecular layer, and the inclusions are adsorbed layer by layer in the filter grid until blockage.

Aluminum Casting Filtration Rectification mechanism

The huge purification effect obtained by filter filtration and purification of metal during the pouring process enlightens us to study its purification mechanism from the flow pattern of molten metal.

In the pouring process, most of the metal liquid is filled into the cavity in a turbulent state, especially in the initial stage of pouring, the molten metal enters the cavity from a certain height.

Due to the meandering and bending of the flow path of the ceramic foam filter, the rectifying ability of the liquid metal from turbulent to laminar flow is strong.

The rectification of the filter causes the molten metal, which originally had a very strong turbulent flow, to become laminar when passing through the filter.

After it has passed through the filter, it is necessary to go through a longer transition zone before returning to the original turbulent state.

In this transition zone, the liquid flow can no longer develop into turbulent flow or small turbulence, avoiding the secondary oxidation of the metal and the scouring of the mold, thereby preventing the formation of slag blocking of secondary oxide inclusions. effect.

Sorry, the comment form is closed at this time.