27 9月 Aluminum degassing effects of different inert gases

For aluminum degassing, during the high-temperature smelting process of aluminum and its alloys in the smelting furnace, the influence of pure metal ingots, intermediate alloys, scraps, high-temperature furnace gas, refractory materials, and tools on the purity of aluminum melts causes the ingots to produce pores and slag inclusions and other metallurgical processes defect. Therefore, in the production process, refining with flux and inert gas is used to reduce the generation of metallurgical defects. However, the refining treatment in the furnace has the following problems:

Advantages & disadvantages of different insert gases for aluminum degassing effects

(1) The refining flow of pure inert gas is large, the bubbles are large, the melt is tumbling seriously, and it is easy to oxidize and form slag, and the aluminum degassing effect is good, but the slag removal effect is poor; and the cost of large flow argon is high, and MgN and AlN are easily generated with nitrogen. , the degree of purification is poor.

(2) The toxicity and activity of chlorine purification are high, the reaction is too intense, the harm is many, and the purification effect is even worse.

(3) Mixed gas refining using nitrogen and chlorine gas or argon and chlorine gas mixture for refining, the purification effect is not obvious, it is harmful to human health, and it seriously corroded the surrounding equipment.

(4) Although pure refining flux purification can better remove oxidized slag inclusions, and can also remove some gases, it is not thorough and will also bring flux slag inclusions.

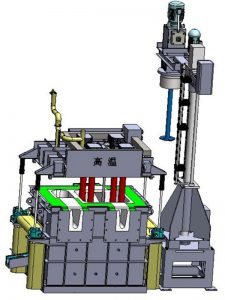

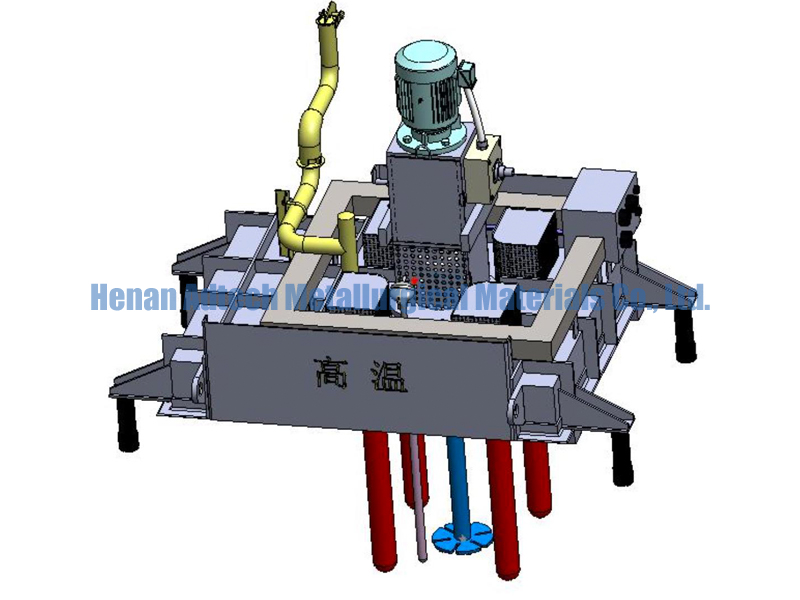

(5) The aluminum degassing effect of the online degassing unit is very good, but the effect of removing impurities is very small, and the cost of equipment and operation is expensive.

In summary, the most economical, practical, and effective in-furnace powder spray refining with flux purification effect and gas purification effect is the most effective refining method for aluminum alloy melts. However, the hydrogen content of the aluminum melt in the smelting furnace is between 0.24 mL/100 g and 3.0 mL/100 g, so the ingot cannot meet the usual quality requirements and must be further purified; thus the furnace was developed. External online degassing and filtration purification technology, this paper focuses on the progress of online degassing process technology.

No Comments