18 Oct Aluminum Liquid Degassing System

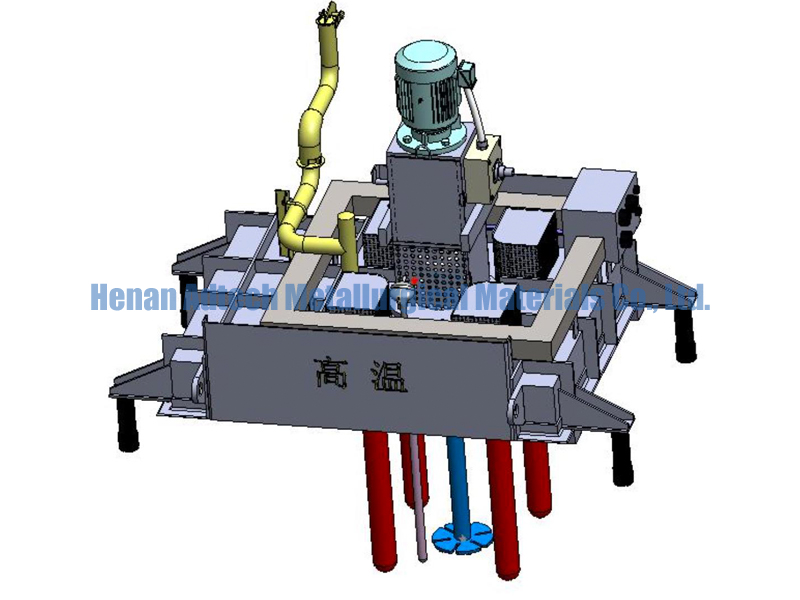

Aluminum Liquid Degassing System

AdTech is a professional manufacturer of aluminum processing equipment. Its main products are an aluminum alloy melting and holding furnace, aluminum liquid flow tank, refining agent, refining dusting machine; degassing unit, filter box; various aluminum liquid ladles, transfer packages; ladle preheater, baking pack; aluminum liquid temperature measuring thermocouple protection tube.

The aluminum liquid degassing system is also called degassing machine, degassing equipment, rotary refining machine, dehydrogenation machine, decontamination equipment, dehydrogenation machine, slag removal machine, aluminum liquid cleaning equipment, fixed deaerator, aluminum Alloy rotary air refining machine, aluminum alloy refining and degassing equipment, dual gas aluminum liquid refining degassing machine, online laundering degassing device, aluminum alloy refining dusting machine, aluminum liquid refining machine, online pot lid deaerator, box type degassing device and trough type degassing device and so on.

Aluminum liquid degassing system features:

1. Divided into movable and fixed modes, which apply to different operating environments.

2. The degassing rate is high, shortening the smelting time and reducing the production cost.

3. It is suitable for purifying the aluminum liquid in the furnace, ladle, and static box.

Principle of aluminum liquid degassing unit:

The solubility of hydrogen in aluminum liquid is very high. It will reduce the physical properties and mechanical processing properties of castings and cast high-quality castings. The hydrogen content in the aluminum liquid must be controlled at a low level. The rotor of the degassing refining equipment can effectively disperse the inert gas into fine bubbles, and evenly spread and float in the aluminum liquid. The partial pressure of hydrogen in the aluminum liquid is higher than that in the bubble, and the hydrogen gas will diffuse into the inert gas and float up to the liquid surface with the bubble, thereby effectively reducing the hydrogen content in the aluminum liquid, and the floating bubbles will be fine inclusions in the aluminum liquid. Brought to the surface of the aluminum liquid, captured by the covering agent, and removed

The aluminum liquid degassing system rotates the rotor through a rotating graphite rod and the rotor injects a quantity of inert gas into the aluminum liquid. The rotor breaks up the inert gas into fine bubbles and evenly disperses it in the molten metal. The useless hydrogen and non-metallic inclusions are trapped by the bubbles of the inert gas and float to the liquid surface. The aluminum liquid purification effect is good, and the hydrogen content of the 100g aluminum alloy liquid can reach 0.1mL (pinhole degree grade 1) or less, and dehydrogenation. The rate is high, the alloying elements are less burnt, and the composition and temperature of the aluminum alloy are uniform.

No Comments