15 Jun Aluminum Molten Aluminum Refining

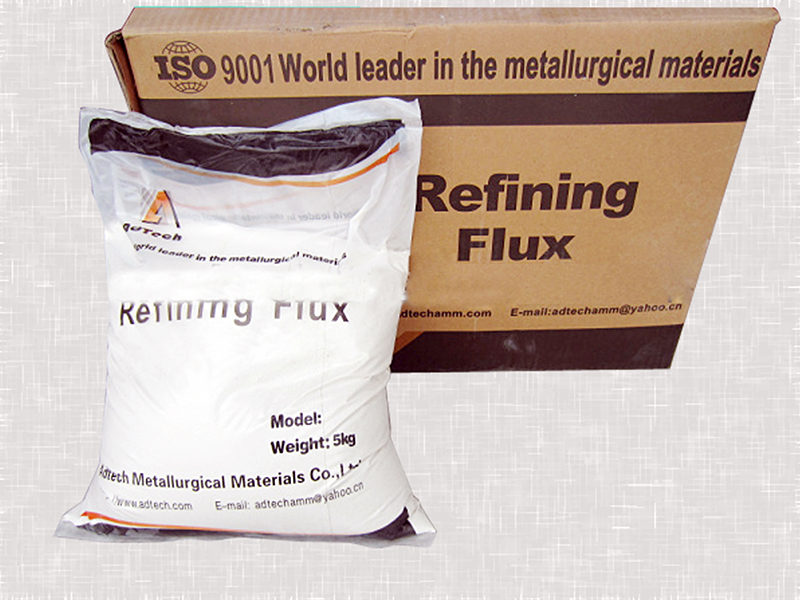

Aluminum Molten Aluminum Refining can play the role of degassing and removing impurities, so that the aluminum alloy solution is more pure and improve its mechanical properties.

There are many precautions for adding refining agent. The following describes the specific use method.

Adding appropriate amount of Aluminum Molten Aluminum Refining when smelting aluminum products can effectively remove hydrogen and floating oxidized slag contained in the aluminum liquid.

Mainly because the refining agent is easily decomposed at high temperature, especially the gas produced is prone to chemical reaction, and the strong adsorption capacity of the slag inclusion can allow hydrogen to escape from the melt, so it can play a clear slag removal effect.

It is a good choice for enterprises with high requirements for smelting pure aluminum, and it has been unanimously praised and recognized by customers and friends.

The method of using the refining agent is relatively simple, you can learn more about its use before using it.

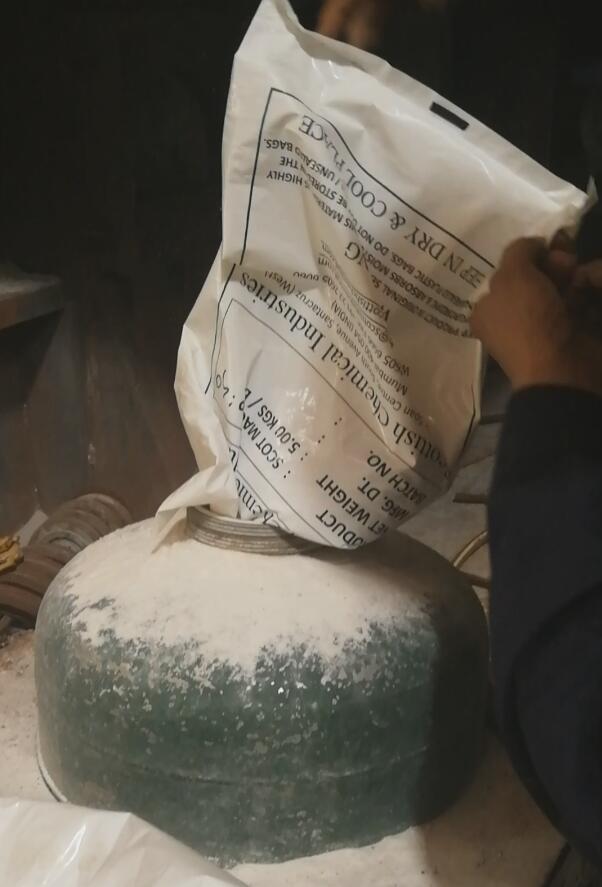

Especially sprinkle it evenly on the liquid surface, quickly press it into the aluminum liquid, stir it thoroughly and let it sit, then slag.

In addition, in the process of using, you can use the sprayer, and it will be better to use inert gas to inject it. The amount is about 0.3% of the weight of the aluminum liquid. If the purity of the aluminum liquid is relatively high, see more Refining agent.

Aluminum Molten Aluminum Refining’s spraying method has more contact area with aluminum liquid. The powdery refining agent is sprayed into the solution through the powder spraying machine.

Nitrogen and argon are generally used as the carrier for spraying, and a large number of dispersed bubbles will be formed in the aluminum alloy solution. During the bubble floating process, the aluminum melt will be fully contacted to remove the gas and inclusions in the aluminum liquid in time.

Adding the refining agent should be added according to the weight of the aluminum liquid, because too much or too little will affect the properties of the aluminum alloy, so it must be calculated before adding.

During the operation of the Granulated Flux, the operator should freely control the refining flow through the barometer and powder feeder, so as to control the rolling degree of the aluminum liquid, which can reduce secondary pollution.

The amount of refining agent added is 0.10-0.20%, and the customer should choose according to the actual situation during use.

After the refining agent is added, it must be fully agitated to give full play to the role of the refining agent. The specific slag and pouring should be determined according to the situation. Generally, the pouring is carried out in advance, but the residue cannot be poured.

The above is the introduction of the use method of refining agent. The refining agent contains a variety of metal elements, which plays an important role in the smelting of aluminum alloys. After addition, it can also change the properties of aluminum alloys and make it more widely used, so refining Agent is essential in aluminum alloy smelting.

Sorry, the comment form is closed at this time.