24 10月 Aluminum plant filter

Aluminum plant filter

Aluminum Factory Filters,Aluminum Industrial Filters,Foam Ceramic Filters,Microporous Ceramic Filters

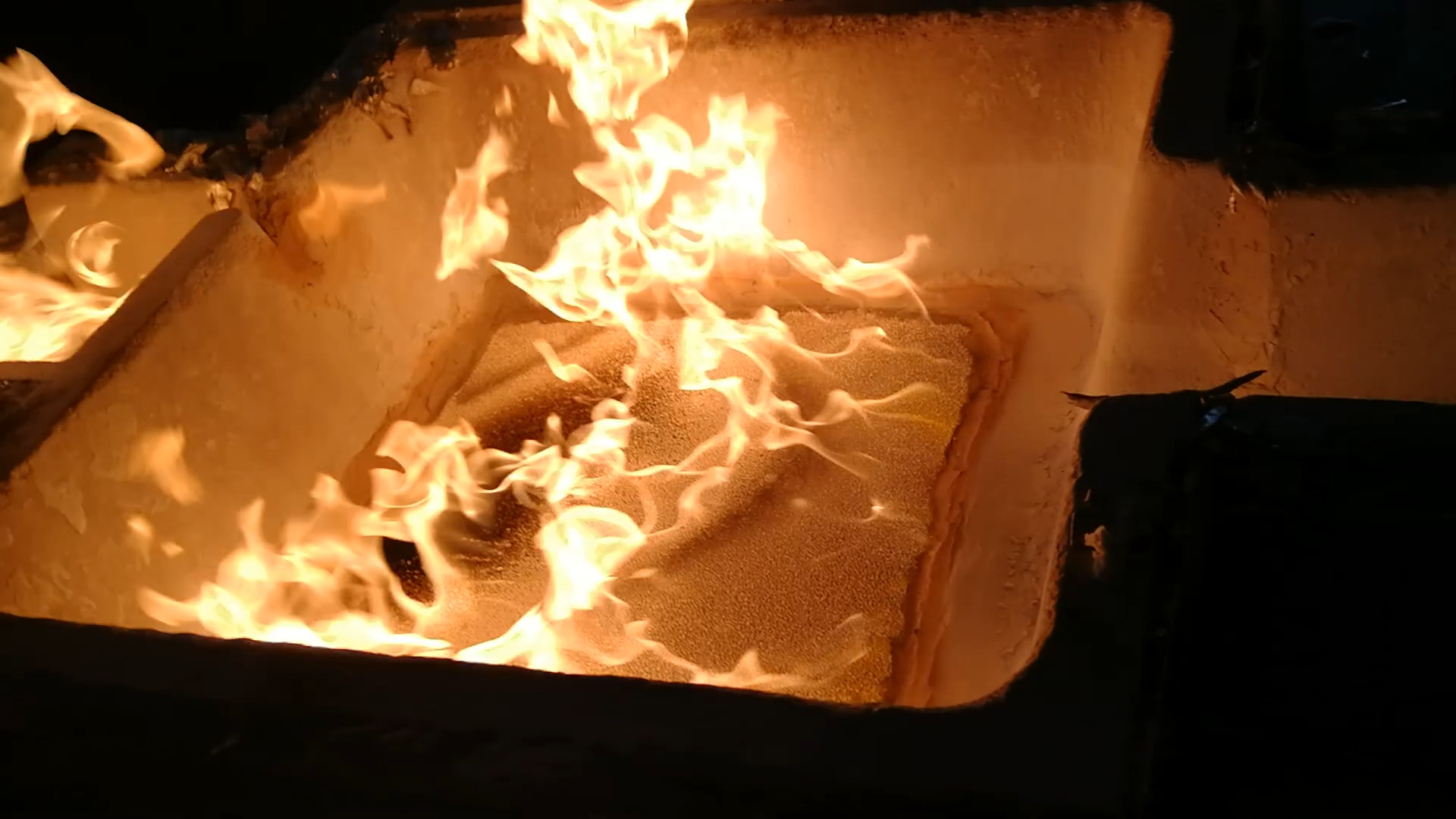

Aluminum plant filter is made of non-stick aluminum material.

It has the characteristics of non-stick aluminum. The product is white or milky white. It is suitable for the production of high quality and high requirements aluminum and aluminum alloy purification process through physical adsorption and Chemical action, which can effectively remove various oxidation inclusions generated during aluminum smelting process, thereby reducing casting defects, improving casting quality, and providing high-quality materials for further deep processing.

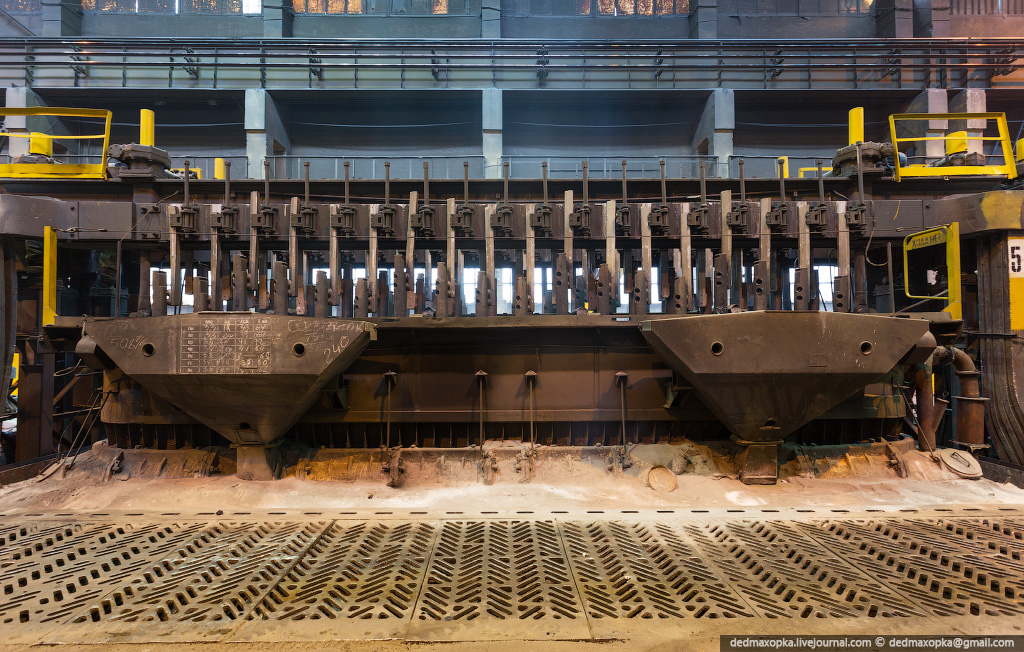

Aluminum plant filter should be preheated before use.

The filter plate is completely sealed in the aluminum water filter box to ensure that all the aluminum water passes through the filter plate, and the total amount of filtration must not exceed the specified limit. If the amount of slag in the aluminum water is too high, multiple pieces of filtration or reduction should be adopted. The amount is adjusted.

The results of performance characterization show that the foam with modifier added has a through-hole ratio of over 90% and a compressive strength of up to 2MPa. Considering the shape stability factor of the material, about 8% is added to the basic component. Bentonite can optimize the modification effect of the aluminum plant filter.

Aluminum plant filter is made of high-quality high-purity zirconia, which is made of unique formula and advanced environmental protection technology. The three-dimensional network structure is uniform, with high strength, stable texture, no slag, high temperature resistance and strong thermal shock resistance.

Excellent performance, suitable for purification and filtration of high temperature aluminum and aluminum alloy solution, can filter non-metallic slag and slag as small as micron, make the surface of casting more smooth, reduce machining loss, filter can make aluminum liquid more evenly Filled with the cavity, the molten metal has a higher turbulence tendency during casting, and is finally converted into a very stable laminar flow through the turbulent flow of the three-dimensional pore structure, and the laminar flow has better filling of the cavity, thereby reducing the metal solution pair. Impact corrosion of the casting cavity, and significantly reduce the scrap rate, reduce production costs, and increase labor productivity.

No Comments