12 Jun Aluminum Refine Agent

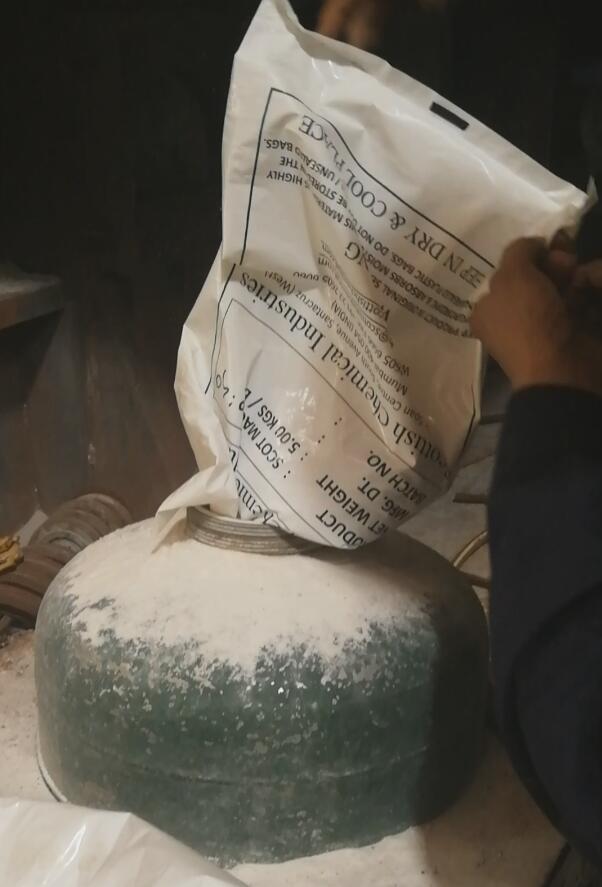

Aluminum Refine Agent is a white powder or granular solvent. It is mainly composed of a variety of inorganic salt treatments according to a certain proportion, because it is mainly used to remove hydrogen and floating oxidized slag inside the aluminum liquid.

Introduction to the role and usage of Aluminum Refine Agent

Because some components in the Refine Agent are easily decomposed at high temperature, the generated gas is easy to tomb with hydrogen, and the adsorption capacity of the slag is strong, which can quickly allow hydrogen to escape from the melt, and also has the effect of cleaning the slag.

Refine Agent is especially suitable for pure aluminum smelting, suitable for the last step of refining, because the removal effect is good, and it is unanimously praised and recognized by our customers.

To use the refining agent, you only need to sprinkle it on the liquid surface, quickly press it into the aluminum liquid, after fully stirring and standing, then slag.

In the process of use, it is necessary to use a spray machine, and it is better to use an inert gas to spray the refining agent into the aluminum liquid. The general dosage is about 0.3% of the weight of the aluminum liquid, depending on the purity of the aluminum liquid.

The refining agent produced by our company can be deformed according to user’s requirements, and it needs to be stored in a dry place. If it is inadvertently damp, it will be used again after drying.

Because the refining agent is processed by a special process, it needs to be isolated from the air when it is used, and it must be evenly sprayed into the aluminum liquid, so that it can play a corresponding role.

The refining agent combines refining and solvent refining, has a good degassing effect, requires less amount when added, and the overall operation is convenient and simple, thereby reducing the labor intensity of work. The refining agent produced by our company has high purity, which has been unanimously respected and recognized by our customers.

During smelting, the order and method of loading the furnace materials not only affect the smelting time, metal burning loss, and heat energy consumption, but also affect the quality of the metal melt and the service life of the furnace.

What is the role of the coating agent, slagging agent, slag cleaning agent, Aluminum Refine Agent, etc. used in the aluminum alloy melting process?

The charging sequence of the aluminum alloy melting process should be reasonable. The correct charge depends on the nature and condition of the charge material added, and it should also take into account the fastest melting rate, the least burning loss, and accurate chemical composition control.

When loading, first install small pieces or thin pieces of scrap, aluminum ingots and large pieces in the middle, and finally the intermediate alloy. The intermediate alloy with easy melting point is installed in the middle and lower layers. The charged materials should be evenly distributed in the molten pool to prevent overweight.

When the temperature of the aluminum alloy reaches about 660-720 degrees, the refining agent is added, and the tool is pressed to the bottom until no bubbling occurs. It is mainly used to remove hydrogen from the aluminum liquid. The refining agent: zinc chloride.

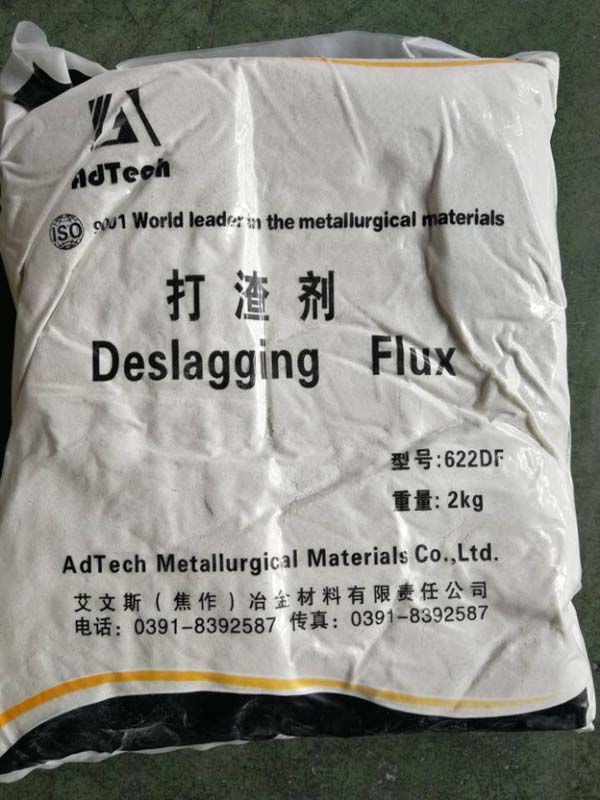

After refining, CLPbD slagging agent is added, and the slag is removed after fully stirred with a tool, which is mainly used to remove impurities in the aluminum liquid. CLPbD slagging agent is mainly used for lead alloy smelting.

After cleaning the slag, spread the covering agent such as expanded perlite and expanded graphite on the surface to prevent the hydrogen in the air from entering the aluminum liquid and keeping it warm.

Specific functions of covering agent, slagging agent, slag cleaning agent, refining agent, etc.

The slag-removing agent and the slag-removing agent should be the same thing. When the temperature of the aluminum alloy reaches about 720 degrees, the refining agent is added. Press the tool to the bottom and move slowly until it does not bubble. It is mainly used to remove hydrogen from the aluminum liquid. After refining, add slagging agent, stir thoroughly with tools and remove the slag. It is mainly used to remove impurities in the aluminum liquid. After cleaning the slag, spread a covering agent on the surface to prevent hydrogen in the air from entering the aluminum liquid.

Sorry, the comment form is closed at this time.