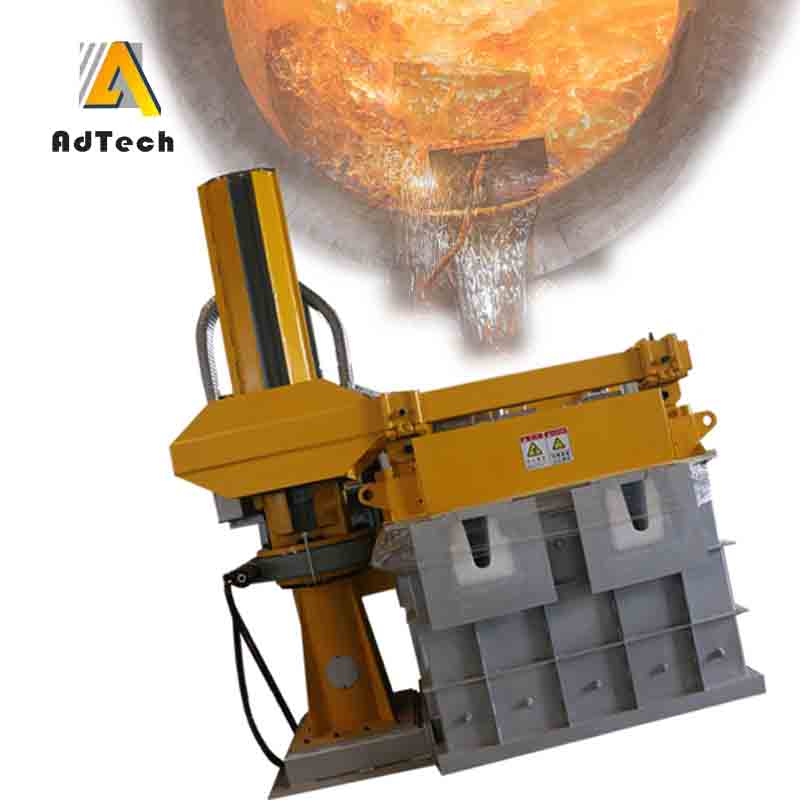

20 Nov Aluminum Slag Remover

Aluminum Slag Remover uses a rotor to blow inert gas (argon or nitrogen) into molten aluminium to break them into a large number of dispersed bubbles and disperse them in the aluminum liquid.

Bubbles in the melt rely on the gas partial pressure difference and the principle of surface adsorption to absorb hydrogen in the melt, adsorb oxidized slag, and be taken out of the melt surface as the bubbles rise, so that the melt can be purified.

Because the bubbles are small and dispersed, they are evenly mixed with the rotating molten liquid, and then rotate and slowly rise in a spiral shape.

When in contact with the melt, the air flow generated by continuous linear rise will not be formed, thereby significantly improving the purification effect. Both argon and nitrogen can be used to degas the molten aluminum. The purity of the inert gas must be above 99.95%. It is suitable for purifying and purifying molten aluminum in crucible furnaces, pool furnaces, reflex furnaces, ladles and static boxes. The aluminum degasser is required to work on the cover plate, and the graphite rotor should be extended into the center of the crucible mouth to work.

If you need please contact sales@adtechamm.com

Work efficiency of Aluminum Slag Remover

The rotating rotor breaks the nitrogen (or argon) in the molten aluminum into a large number of dispersed bubbles and disperses them in the molten metal.

Bubbles in the melt rely on the gas partial pressure difference and the principle of surface adsorption to absorb hydrogen in the melt, adsorb oxidized slag, and be taken out of the melt surface as the bubbles rise, so that the melt can be purified.

Because the bubbles are small and dispersed, they are uniformly mixed with the rotating molten liquid, and then they rotate in a spiral shape to slowly float up. When in contact with the molten liquid, the airflow generated by a continuous linear rise will not form, thereby significantly improving the purification effect.

Both argon and nitrogen can be used as inert gases to degas the molten aluminum. The purity of the inert gas must be above 99.95%.

Sorry, the comment form is closed at this time.