18 3月 Boron Nitride

Boron Nitride is an inert inorganic high-temperature lubricating material. It does not stick and does not wet the molten metal. It can completely protect the surface of refractory or ceramic utensils in direct contact with molten aluminum alloy and slag, which greatly prolongs the service life of such utensils.

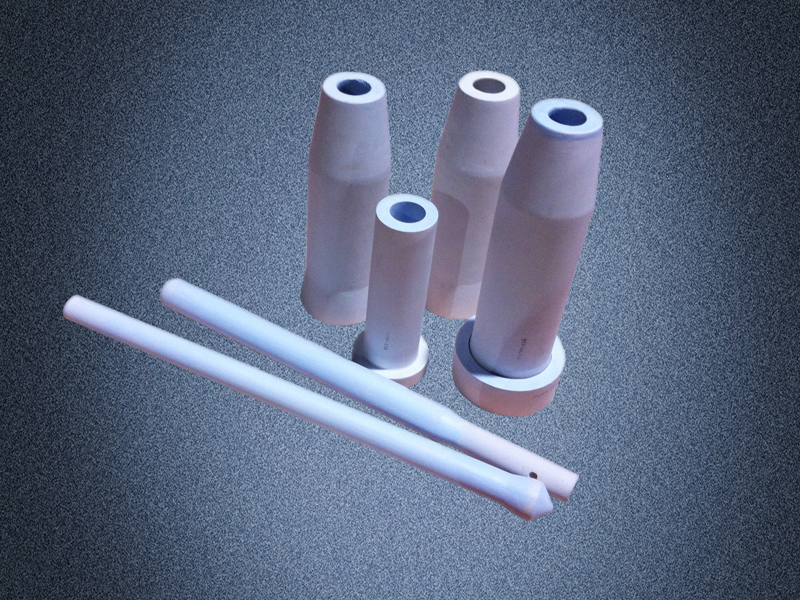

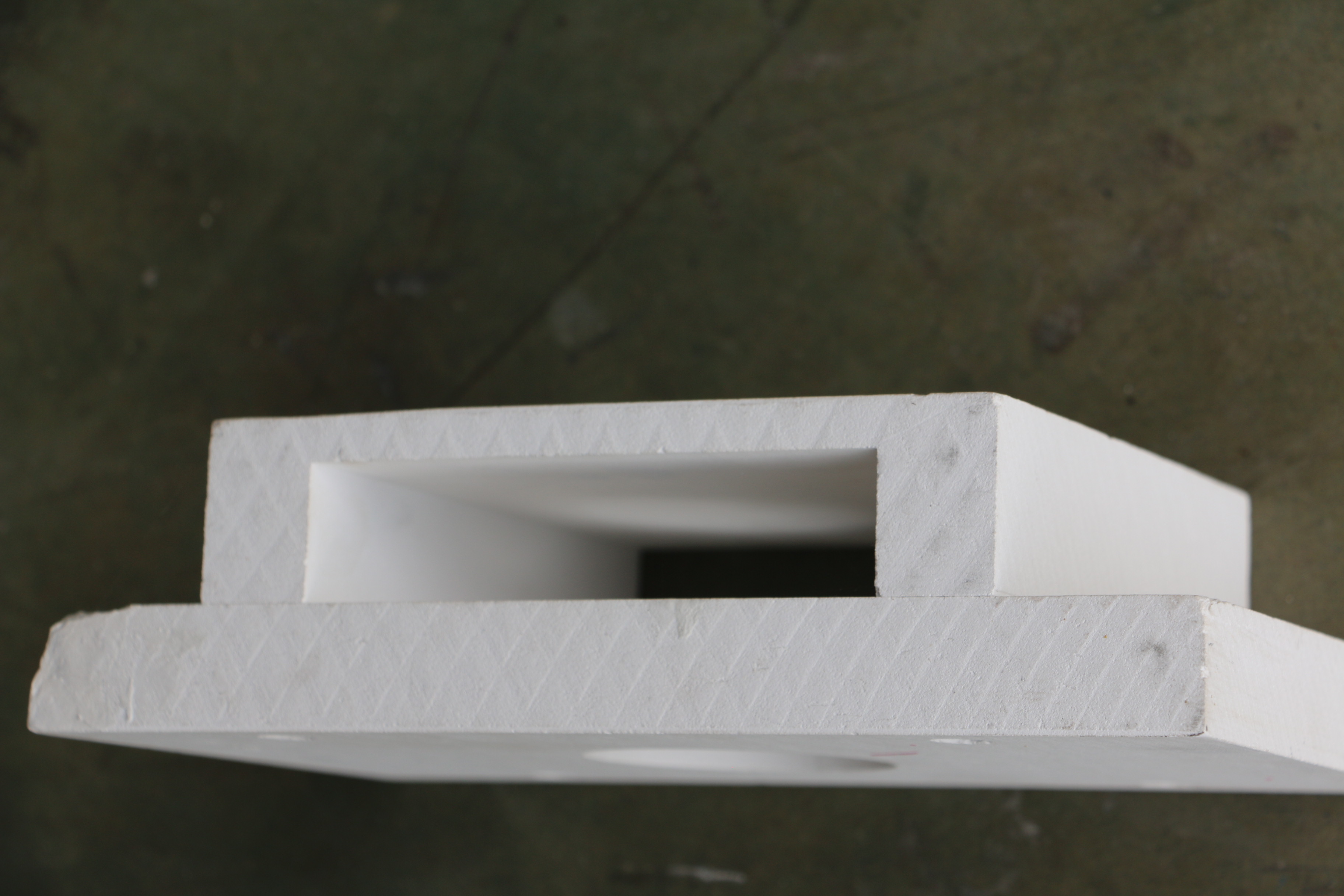

Boron Nitride is widely painted on Molten Aluminum Launder, hop-top casting for aluminium alloy, Castertip, CFF filter box, Degassing Units, Cff machine and other materials, to protect the mold against corrosion and extend the life of refractory materials.

At the same time, in the production process, preventing fine impurities from penetrating into the metal liquid, causing secondary pollution, and greatly improving product quality.

In high temperature environments, Boron Nitride has excellent lubricity and oxidation resistance. With boron nitride’s unique physical and chemical properties, it still protects its unique lubricity, non-sticking and anti-metal properties even at extremely high temperatures. Corrosive oxidation.

In addition to the protection of various refractory materials, it also has excellent protection against chemical corrosion and anti-adhesion.

How to use Boron Nitride

1. Clean the surface of the material to be protected, and then spray boron nitride after rinsing

2. After the new flow tank is diluted by 1: 4, the brush tank / furnace wall is about 23 microns thick; after the old flow tank is diluted by 1: 6, the brush tank / furnace wall is about 20 microns thick.

3. Use a sponge (brush, spray gun) to apply the diluted boron nitride coating on the surface of the material, or adjust the dilution factor as required.

4. After coating, dry at about 300 ℃, use after the coating is dry.

5. For inaccessible local coatings (such as the inner wall of a thin tube), the coated parts can be immersed in the diluted boron nitride coating, and the excess coating will flow out naturally after being taken out and used after drying.

6. The coating should be uniform, the surface must not be agglomerated, and it should not be applied too thickly

Sorry, the comment form is closed at this time.