10 5月 Boron Nitrogen

Boron Nitrogen Coating

Boron Nitrogen Coating has excellent non-wetting properties with aluminum, even a very thin layer is sufficient to effectively separate the aluminum melt from the matrix material.

Boron Nitrogen Coating Feature

1. Does not react with molten metal, the additive free energy is small, and it will not be replaced with molten metal in situ, which is the key factor for the length of use of the coating.

2. Achieve thick coating and thick coating, no cracking, peeling off, the actual use of a large thickness of 5mm, slightly polished surface, still produces a smooth surface. Impact resistant, frictionless, non-wetting, longer protection and more stable to the base material. The same applies to thick coatings of highly thermally expandable substrates such as metals.

3. Ultra-fine group, larger specific surface area and stronger adhesion.

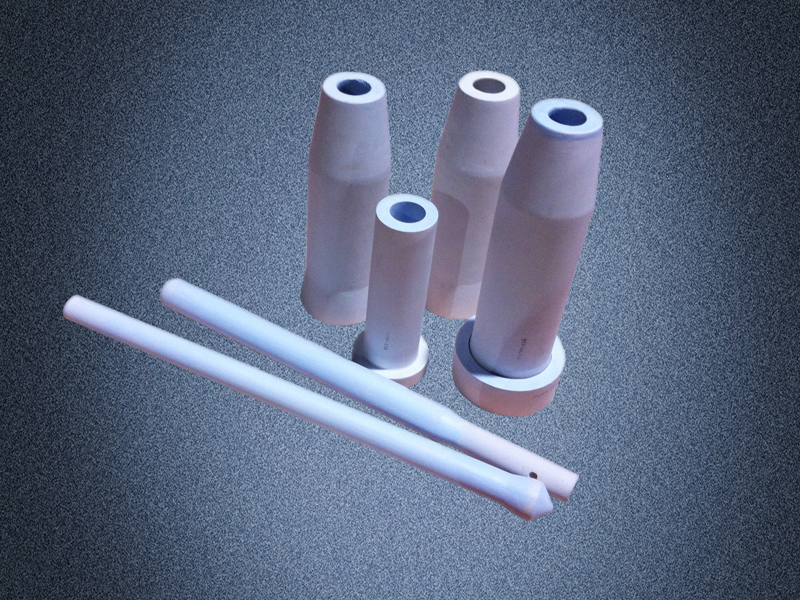

Boron nitride coatings are widely applied to the surface of chutes, shunts, distribution chutes, casting linings, filter boxes, adapter plates, casting nozzles and other materials.

In addition to the gas box, the lining of the melting furnace can be painted.

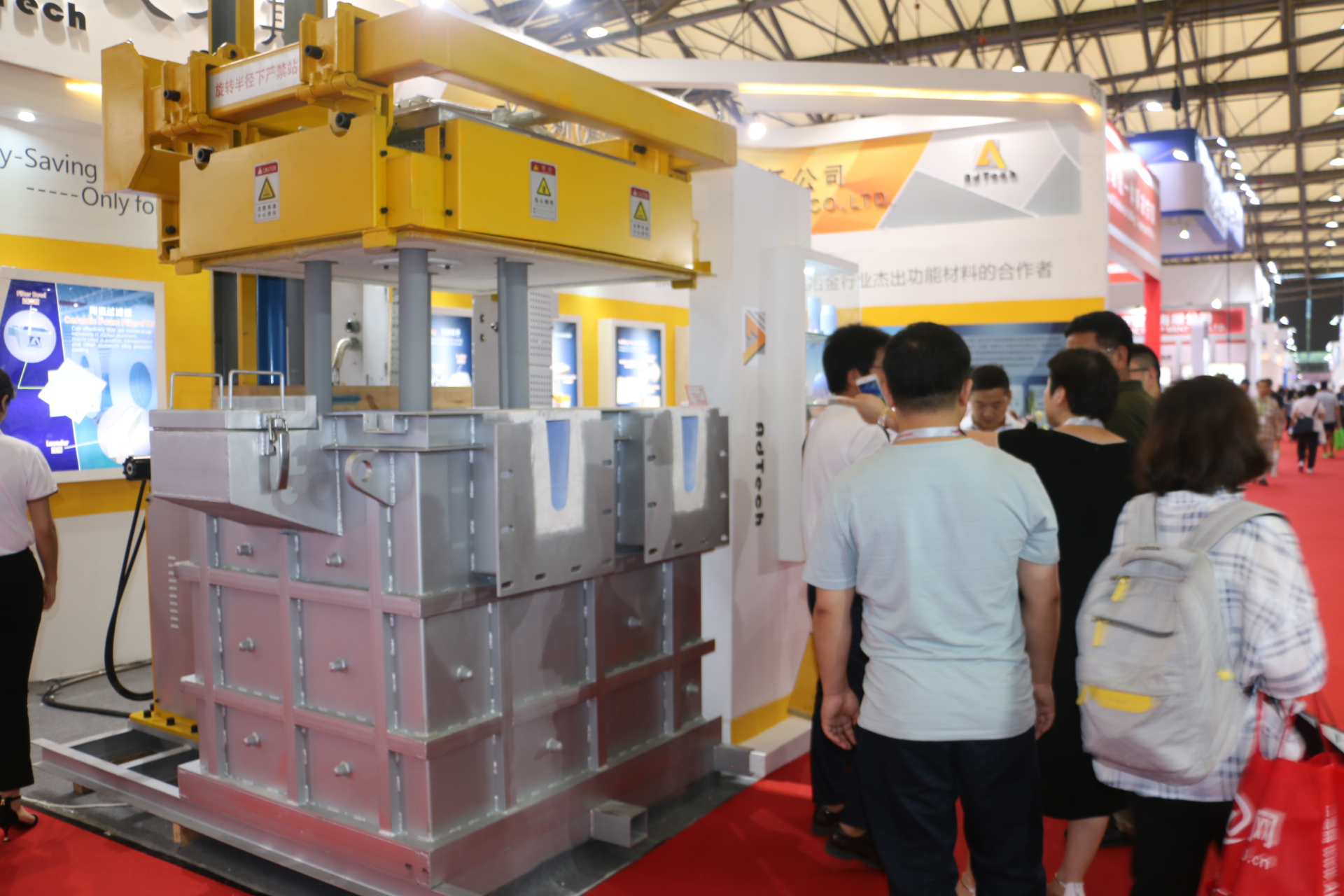

Specially formulated coatings can be used in die casting of mobile phone aluminum.

The use of the pressure chamber in the die casting machine can reduce the nodule in the medium pressure chamber and greatly improve the working efficiency of the die casting machine. The special sky blue makes the secondary spray easier to separate. Colored places can not be sprayed.

Boron nitride coating has the following effects

1. Protect the mold from corrosion and prolong the service life of the refractory.

2. In the production process, prevent fine impurities from penetrating into the molten metal, causing secondary pollution and greatly improving product quality.

3. It has excellent lubricity and oxidation resistance in high temperature environment. Boron nitride has its unique physical and chemical properties, and it protects its unique lubricity, non-stickiness and anti-corrosion oxidation even at extremely high temperatures.

4, to prevent aluminum in the high-alloy mold, extend the working time of the iron mold, and greatly improve productivity.

Boron nitride coating using steps

1. Clean the surface of the material to be protected, rinse and spray with boron nitride paint.

2. Stir the paint evenly, then brush or spray it on the surface of the work lining. The coating should be even, the surface should not be gathered, and it should not be too thick.

3. Dry naturally for more than 12 hours, dry at 300 ° C, dry the coating and use.

4. For inaccessible partial coatings (such as the inner wall of the thin tube), the coated parts can be immersed in the prepared boron nitride coating. After the removal, the excess material will naturally flow out and be used after drying.

5. When spraying the inner cavity of the iron mold, the iron mold should be heated first, and the spraying effect is better.

The paint has been set for several months, does not precipitate, the surface is not drowning, the quality is very stable, and it has completely reached the quality level of imported products.

Sorry, the comment form is closed at this time.