12 7月 Carborundum Ceramic Foam Filter

Carborundum Ceramic Foam Filter

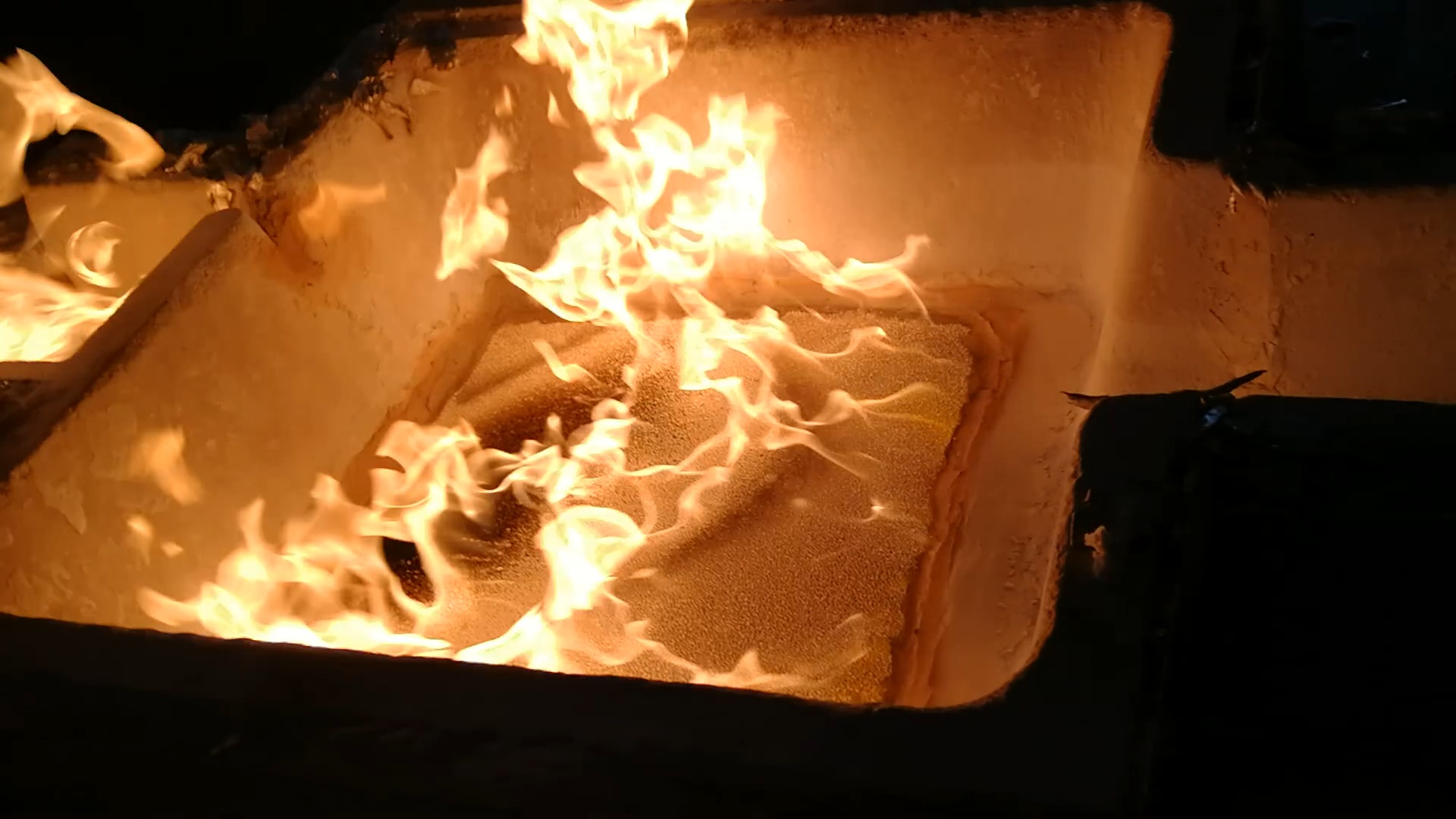

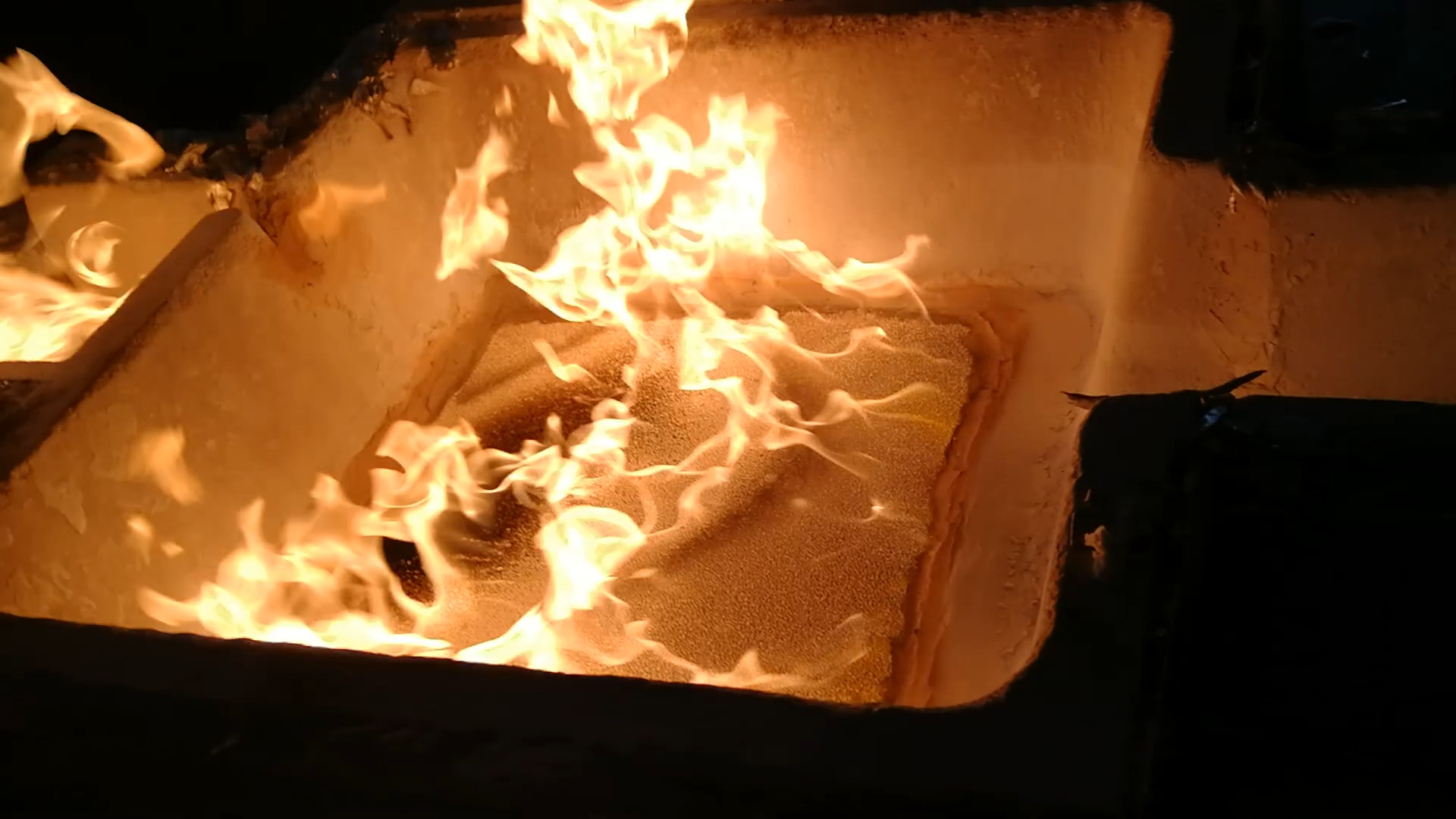

Carborundum Ceramic Foam Filter can effectively remove large inclusions in aluminum liquid and adsorb micron-sized fine inclusion particles to improve surface quality, improve product performance, improve microstructure and improve yield. It is widely used in the production fields of aluminum profiles, aluminum foils, and aluminum alloys. pls contact sales@adtechamm.com to buy it.

Characterization of Carborundum Ceramic Foam Filter

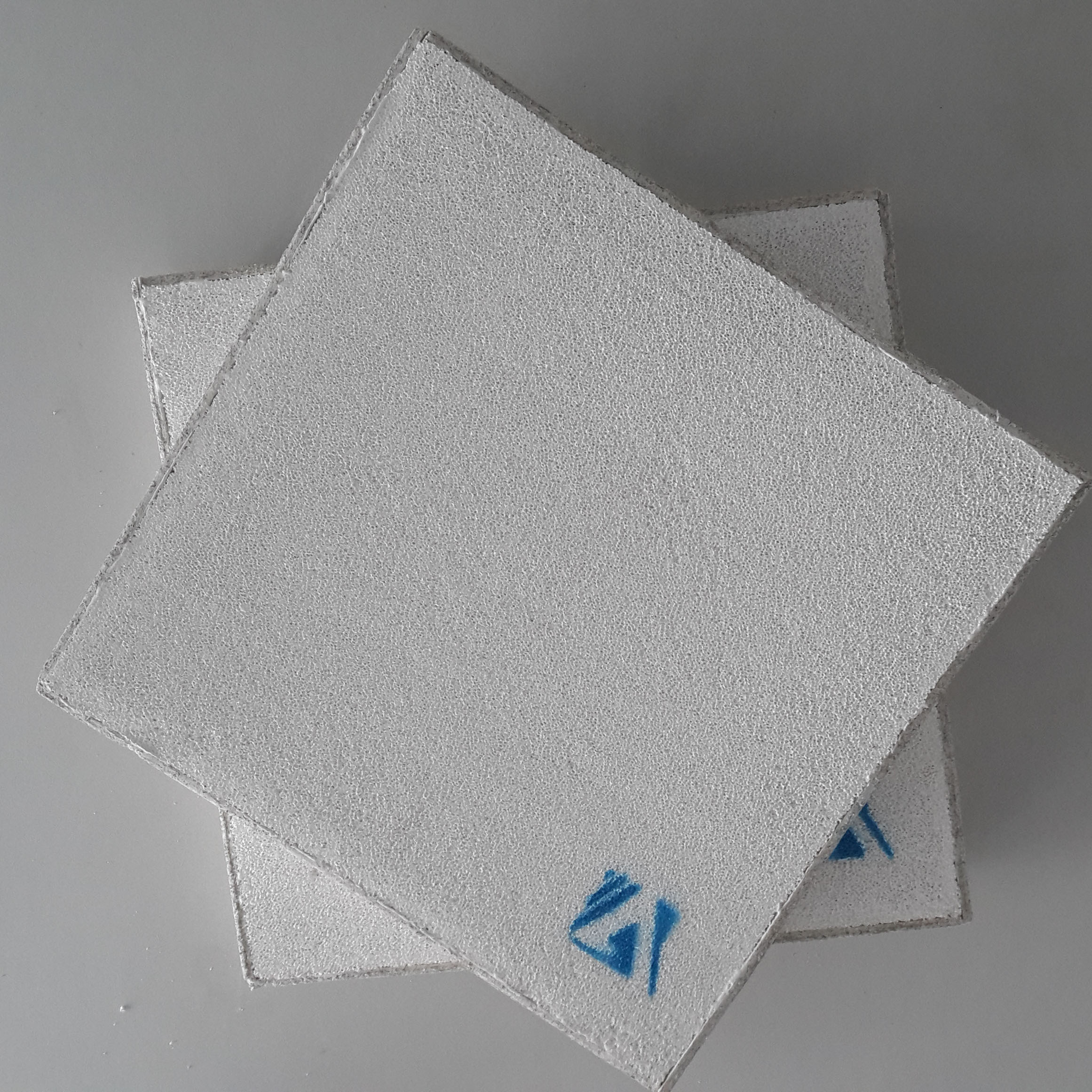

Carborundum Ceramic Foam Filter Structural characterization of specific reactions in pore size, pore distribution, pore shape and porosity;

The pore structure of the membrane is closely related to its filtration transfer performance. The pore size and pore size distribution are the most important parameters of the membrane structure, which directly affect the transfer characteristics of the fluid in the membrane and determine the separation and filtration performance of the membrane surface.

The quality of Carborundum Ceramic Foam Filter in the smelting of aluminum melts is important, which greatly affects the subsequent processing properties and the quality of the final product.

Therefore, all countries in the world attach great importance to the purification of aluminum melt.

There are many reasons for aluminum pollution.

On the one hand, during the smelting process, aluminum is exposed to the furnace atmosphere in a molten or semi-molten state, which is prone to oxidation and easily reacts with water vapor.

Hydrogen is easy to form various forms of non-metallic slag, as well as coarse intermetallic particles and the like.

On the other hand, part of the waste material in the composition charge carries some non-aluminum impurities during the circulation. Since the waste comes from the process waste and waste of the various processes of the factory and the waste outside the factory, the route is different, the composition is complex, and the quality is also poor.

These impurities tend to cause bubbles and inclusions in the slab, which seriously affect the purity of the metal melt, thereby further affecting the processing properties, mechanical properties, corrosion resistance and appearance quality of the product.

Carborundum Ceramic Foam Filter can effectively remove all kinds of fineness in the aluminum water to the micron-sized inclusions, so that the aluminum water becomes a smooth laminar flow, which is favorable for filling.

It has a unique corundum structure, good mechanical strength and chemical stability, superior aluminum washability; tightly controlled hole size and through-hole ratio for stable filtration.

Carborundum Ceramic Foam Filter is surrounded by a sealed ceramic fiber gasket, which helps the filter plate to seal in the filter box, ensuring no metal loss.

This product is mainly used in the purification process of aluminum and aluminum alloy production.

How to use Carborundum Ceramic Foam Filter

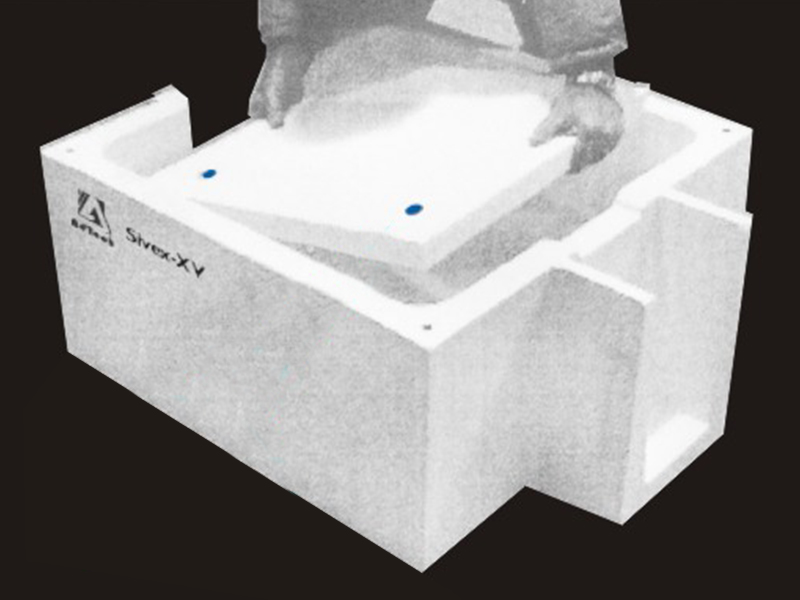

1. Clean the filter box.

2. Gently put the filter plate into the filter box and press the sealing gasket around the filter plate by hand to prevent the aluminum liquid from flowing.

3. Evenly preheat the filter box and filter plate to bring it close to the temperature of the aluminum liquid. Preheat to remove moisture and facilitate initial transient filtration. Preheating can be carried out using electrical or gas heating. Under normal circumstances, it takes about 15-30 minutes.

4. Pay attention to the change of the aluminum hydraulic head during casting. The normal starting head is 100-150 mm. When the aluminum liquid begins to pass, the pressure head will drop below 75-100 mm, and then the pressure head will slowly increase.

5. During the normal filtration process, avoid knocking and vibrating the filter plate. At the same time, the launder should be filled with aluminum water to avoid too much disturbance of the aluminum water.

6. After the filtration is finished, remove the filter plate in time and clean the filter box.

Sorry, the comment form is closed at this time.