25 10月 Cast nozzle plate diverting part

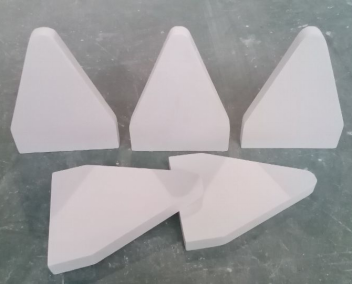

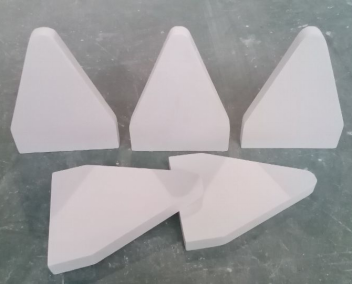

Cast nozzle plate diverting part

Cast nozzle plate diverting part gasket is also called the nozzle plate shunt component.

AdTech Cast nozzle plate diverting part gaskets are matched with the nozzle plate assembly for crystal forming and size control of the aluminum plate with foil blank in the casting and rolling production line.

It is formed by high-purity fiber material vacuum suction filtration and processed by precision equipment.

AdTech nozzle plate diverting parts are matched with the nozzle plate assembly, which is mainly used to adjust the split flow uniformity of the internal flow, so that the internal metal liquid retention temperature error is reduced, and the inside of the cast-rolled coil is effectively protected during the casting and rolling production process. The tissue layer is stable and works better with boron nitride coatings.

Advantages of the nozzle plate shunt parts

1. It adopts high-purity fiber material to absorb and filter, and is processed by precision equipment, with precise dimensional control and suitable density and stiffness.

2. The key parts are strengthened by nano-coating, sealing surface, no delamination and non-stick performance, and enhanced anti-aluminum liquid erosion performance.

3. The internal structure is designed with a rational symmetric flow path to meet the fluid mechanics requirements of aluminum liquid.

No Comments