26 3月 Casting Knowledge – Effect of Ceramic Fiber Castertip on Roll Casting

Casting Knowledge – Effect of Ceramic Fiber Castertip on Roll Casting

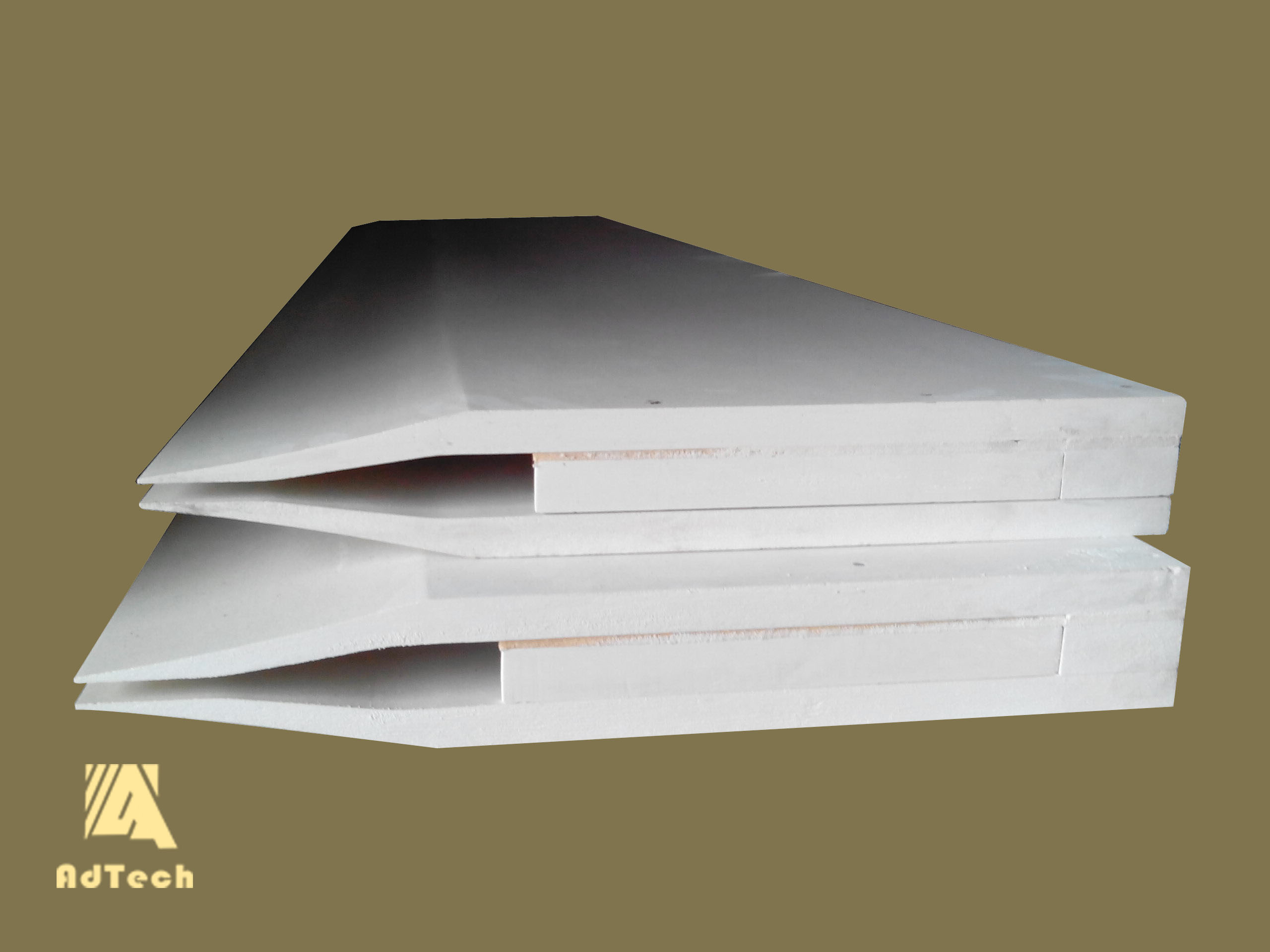

There are other names in the actual application of the Irene casting nozzle plate, such as Ceramic Fiber Castertip,Castertip,Tip Cavity,Nozzle Cavity,Casting Spile,Aluminum Silicate Ceramic Caster Tip,Casting Tips And Nozzle,Concise Aluminum Titanate Riser Tube,Casting Spout,Aluminum Silicate Launder,Ceramic Fiber Castertip,Aluminum Titanate Riser Tube,At All Costs Aluminum Silicate Caster Tip,Alumina Ceramic Parts,Alumina Ceramic Plate.

1. Effect of Ceramic Fiber Castertip on Roll Casting -Cast nozzle plate blocked

When a blockage occurs in the cavity of the casting nozzle plate, the metal is restricted from flowing out of the entire width of the opening of the nozzle plate, so that a slender void defect appears on the surface of the casting strip blank. The pores may be tiny holes that can be observed with the naked eye. Sometimes voids are in the interior of the strip and clear oxide stripes are visible on the surface of the strip.

The method of correction is to increase the metal temperature. It is also possible to stop the roll rotation for a short time to allow the metal to solidify around the stopper and pull it out when it is restarted. In some cases, blockage of the nozzle plate requires replacement of the nozzle plate. Good refining practices are an effective way to prevent clogging of the cast nozzle plate.

2. Effect of Ceramic Fiber Castertip on Roll Casting -Casting plate assembly

Solidification of the metal may occur inside the mouth cavity, or it may occur at the opening of the nozzle plate. The metal solidifies in the mouth cavity as a reduction in the width of the strip or holes in the strip. The reason for this defect may be the leakage of metal from the nozzle plate or the low temperature of the metal in the nozzle plate. Correction methods include:

If the leak is serious, replace the cast plate

· Improve the temperature of the liquid in the front box

Increase casting speed

3. Effect of Ceramic Fiber Castertip on Roll Casting -Fine ripple

This defect is manifested by some lateral, visible light and dark stripes on the surface of the cast strip. The symptoms of this defect are:

·The strip has horizontal dark stripes

· Rough edges

The main motor current value decreases

The cause of this defect is:

The liquid level of the metal is too high. The metal pressure in the nozzle plate causes the metal plate to vibrate, causing fine ripples on the plate surface.

Casting speed is low

Metal temperature is too high

Correction method: reduce the height of the front tank liquid level, reduce the temperature of the aluminum liquid in the front tank, and increase the casting speed to minimize the defects.

4. Effect of Ceramic Fiber Castertip on Roll Casting -Hole

Due to insufficient supply of aluminum liquid, the blank is formed into holes.

The correction method is to increase the height of the metal level in the front tank and reduce the speed of casting.

5. Effect of Ceramic Fiber Castertip on Roll Casting -Tropical

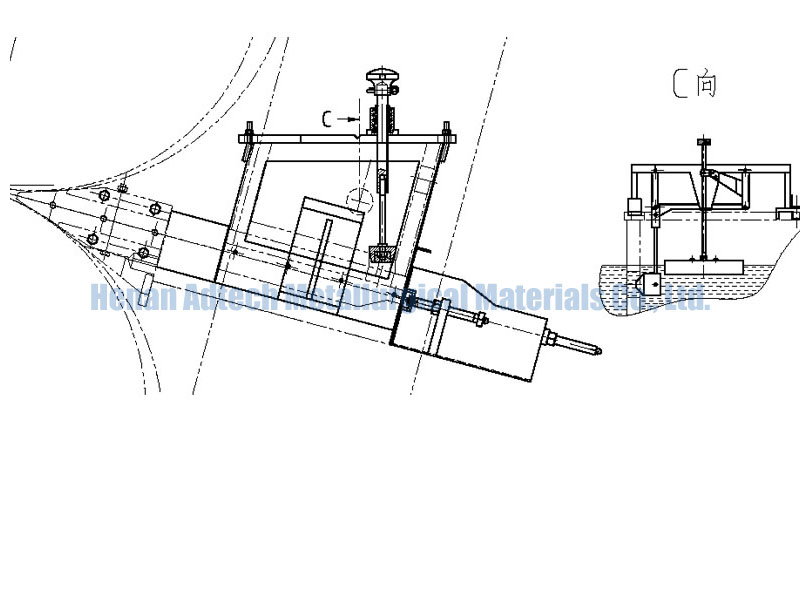

Because the metal temperature is too high relative to the casting speed or the temperature distribution in the nozzle plate is uneven, the metal in the semi-solid state is pressed back into the nozzle plate in the casting zone, leaving irregular holes in the surface after casting. . The correction method is to reduce the metal temperature, reduce the casting speed and reasonable nozzle plate design. A reasonable distribution of the manifold inside the feed nozzle allows the molten metal to be evenly distributed along the width of the nozzle plate, flowing at a uniform rate, and the temperature does not vary by more than ±2°C.

6. Effect of Ceramic Fiber Castertip on Roll Casting -Coarse grains

After the cast strip was pickled, the grain size was measured. The reason for the coarse grains is that the grain refiner feed is insufficient or the casting speed is too low. The correction method is to increase the casting speed and increase the feeding amount of titanium wire. The amount of Ti contained in the aluminum liquid should be 0.006-0.008%.

7. Effect of Ceramic Fiber Castertip on Roll Casting -Columnar grains

The definition of columnar grains is that the coarse dendrite grains produced during casting are oriented in parallel on the strip. This is because the cooling gradient of the strip exceeds the cooling gradient on the sleeve.

The factors causing the columnar grain and the correction method are:

Turbulent metal flow in the nozzle plate. Increase casting speed.

The nozzle plate is in contact with the roll. Will be cast after the plate.

Blocked cavity in the cast nozzle plate.

No Comments