20 11月 Casting Degassing Methods

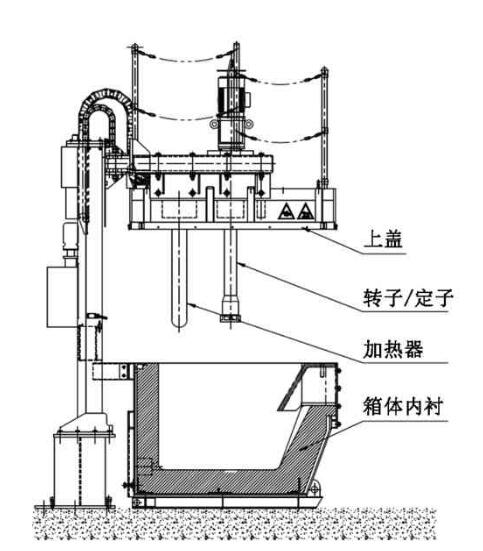

Casting Degassing Methods Aluminum liquid degassing is divided into two types: one is chemical drug degassing, which uses refining flux, and the other uses a degassing machine to degas.

The use of inert gas method and refining agent for degassing has a significant effect and greatly reduces labor and errors caused by manual degassing.

The aluminum liquid degasser has stable performance, simple control, high initial efficiency, and better effect when used with refining agent.

In the deaerator equipment, our company has carried out friendly cooperation with many military enterprises and auto parts production industries.

Nowadays, the die casting industry and the casting industry have higher and higher requirements for product quality.

The main factor affecting the quality of aluminum products is the amount of hydrogen in the molten aluminum.

Therefore, subsequently, the use of liquid aluminum degassing machines is increasing. Casting Degassing Methods is also getting better and better.

Casting Degassing Methods

Aluminum water slag remover, refining degassing machine, hydrogen removing machine, aluminum liquid purifier, aluminum water removing hydrogen machine, aluminum alloy refining degassing machine, hydrogen removing machine, aluminum liquid degassing machine, aluminum water degassing machine, Slag machine, fixed aluminum water deaerator, mobile aluminum water deaerator, hoisting aluminum water deaerator, powder spray type aluminum water deaerator, mobile powder type degassing and slagging integrated machine, aluminum liquid purification Degassing machine, aluminum melting degassing machine, crucible furnace degassing machine, pool furnace degassing machine, smelting furnace degassing machine, launching furnace degassing machine, matching sub-package aluminum liquid aluminum water degassing machine, degassing mixer, melting furnace Aluminum purification equipment, copper liquid slag remover, etc.

Sorry, the comment form is closed at this time.