31 Mar Casting Refractory Porous Ceramic Foam Filter

Casting Refractory Porous Ceramic Foam Filter In order to meet the continuously improving quality of aluminum castings, the use of ceramic foam filter CFF has become more and more important. Filters are also widely used in ordinary sand casting such as tide casting and permanent mold casting such as automobile aluminum parts casting.

The refractory ceramic foam filter uses the filtration process based on the following considerations. On the one hand, filtration makes the flow of molten aluminum orderly and relatively calm; on the other hand, it effectively removes the solid slag in the molten metal and rapidly improves the quality of the casting.

Casting Refractory Porous Ceramic Foam Filter can effectively remove solid inclusions in molten metal, so aluminum alloy can be smoothly forged, aluminum foil and extrusion process to obtain perfect aluminum products.

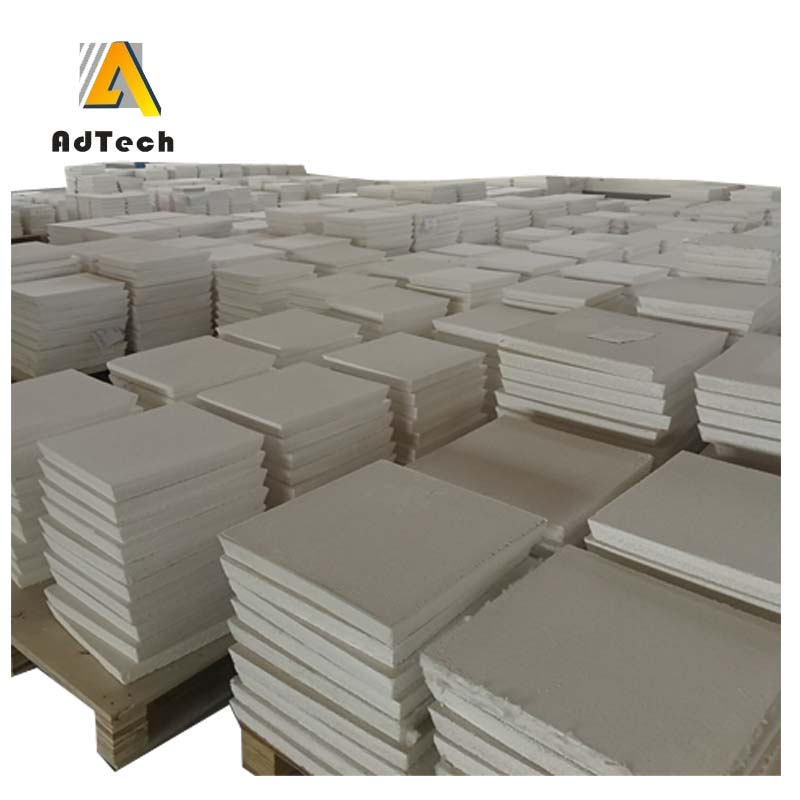

The product has a coarse hole of 20 ppi and a very fine hole of 60 ppi, so there will always be a product standard that suits your requirements. Both ordinary and special sizes required by customers can meet the requirements.

Porosity of Casting Refractory Porous Ceramic Foam Filter

Porosity is the percentage of the total volume of the cavity in the filter plate product relative to the total volume of the filter plate product.

The porosity determines the filtration capacity per unit volume of the foam ceramic filter plate.

The greater the porosity, the greater the filtration flow rate of the filter plate, and the stronger the filtration capacity.

There are currently two main methods for determining porosity.

One method is to calculate the volume of the holes on the filter plate according to Archimedes’s law, that is, use an overflow pipe to pour water into a glass beaker until the water flows out of the overflow pipe.

When the water no longer flows out, the water will be tested.

Gently put all the samples into the water, then the water flows out of the overflow pipe, and measure the amount of water in this part.

Subtract the volume of overflowing water from the physical volume of the filter plate, which is the total volume of the holes on the filter plate.

Another method is to determine the true density and bulk density of the sample to be tested, and then calculate the porosity of the sample according to the following formula.

Both methods have their advantages and disadvantages.

The operation method is simple and convenient, and the detection speed is fast, but its fatal disadvantage is the water absorption characteristics of the filter plate material itself, so the amount of water discharged is less than the actual amount of water. This causes the measured data to be too small.

Although the test process of the second method is more complicated, the influence of the water absorption rate of the filter plate material is excluded during the test, and the data obtained is relatively accurate.

In this standard, the porosity index is determined to be greater than 84%.

No Comments