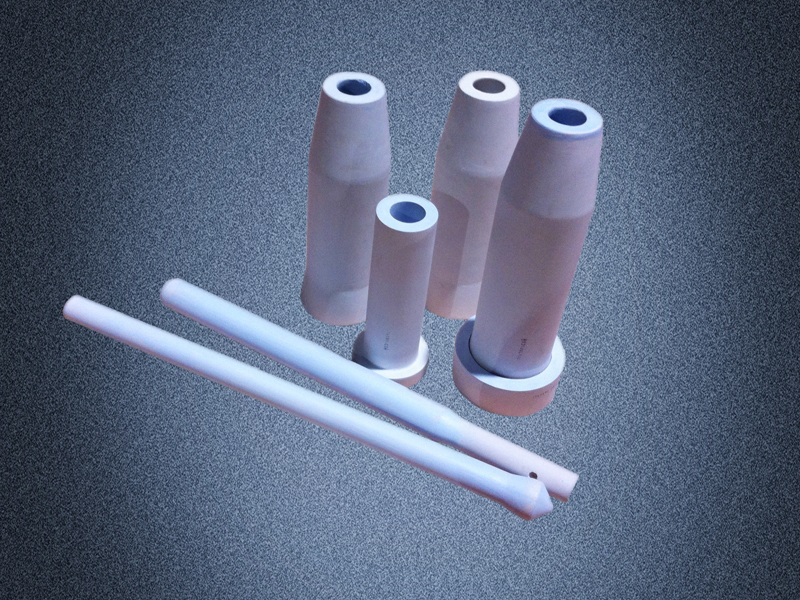

11 1月 Trimet Aluminium Cff Filter

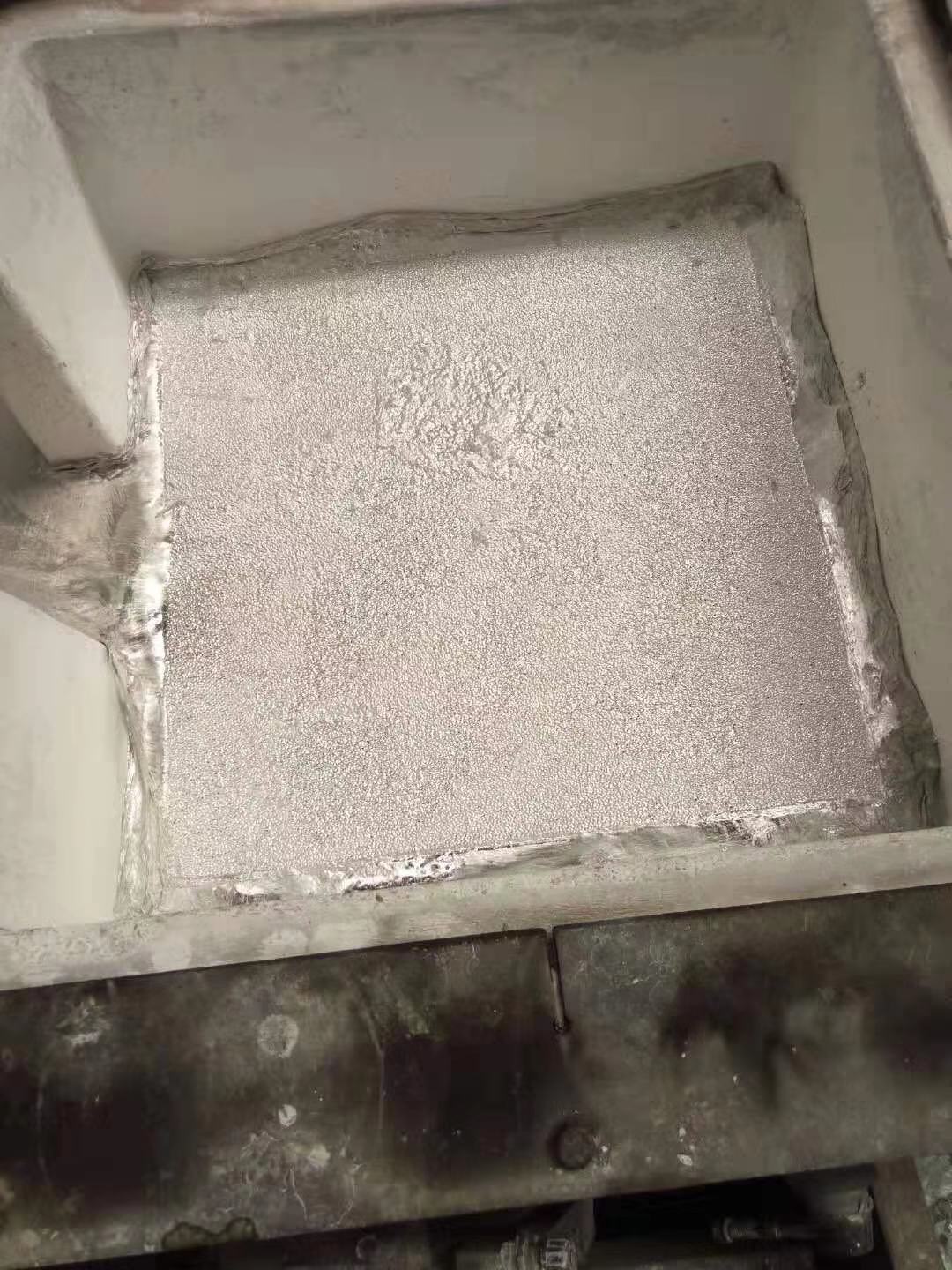

Trimet Aluminium Cff Filter can remove oxides on the aluminum surface, thereby improving casting quality. Today, more and more aluminum plate and aluminum foil manufacturers are using these filters. Adtech is one of the largest ceramic foam filter product suppliers in India and the global industrial...