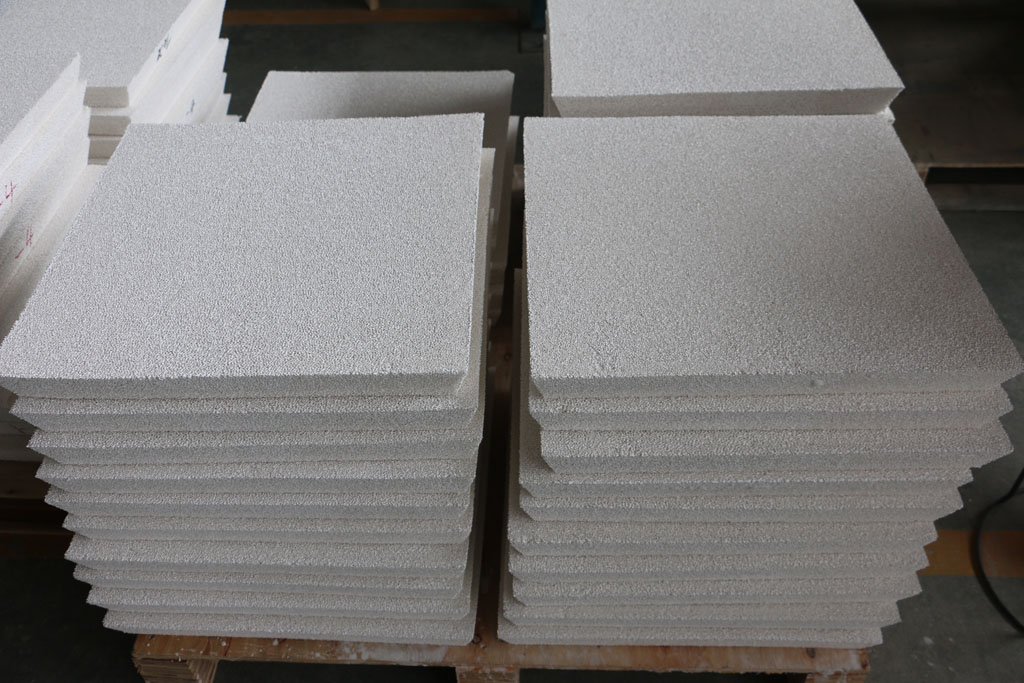

14 1月 Ceramic Foam Filter Al2O3

Ceramic Foam Filter Characteristics of Al2O3 Ceramic Foam Filter Al2O3 is designed for mould-casting metal. Thanks to the mechanism of creation of the “filter cake” on the inlet filter side and thanks to depth filtration inside the ceramic matrix, these ceramic foam filters are an effective...