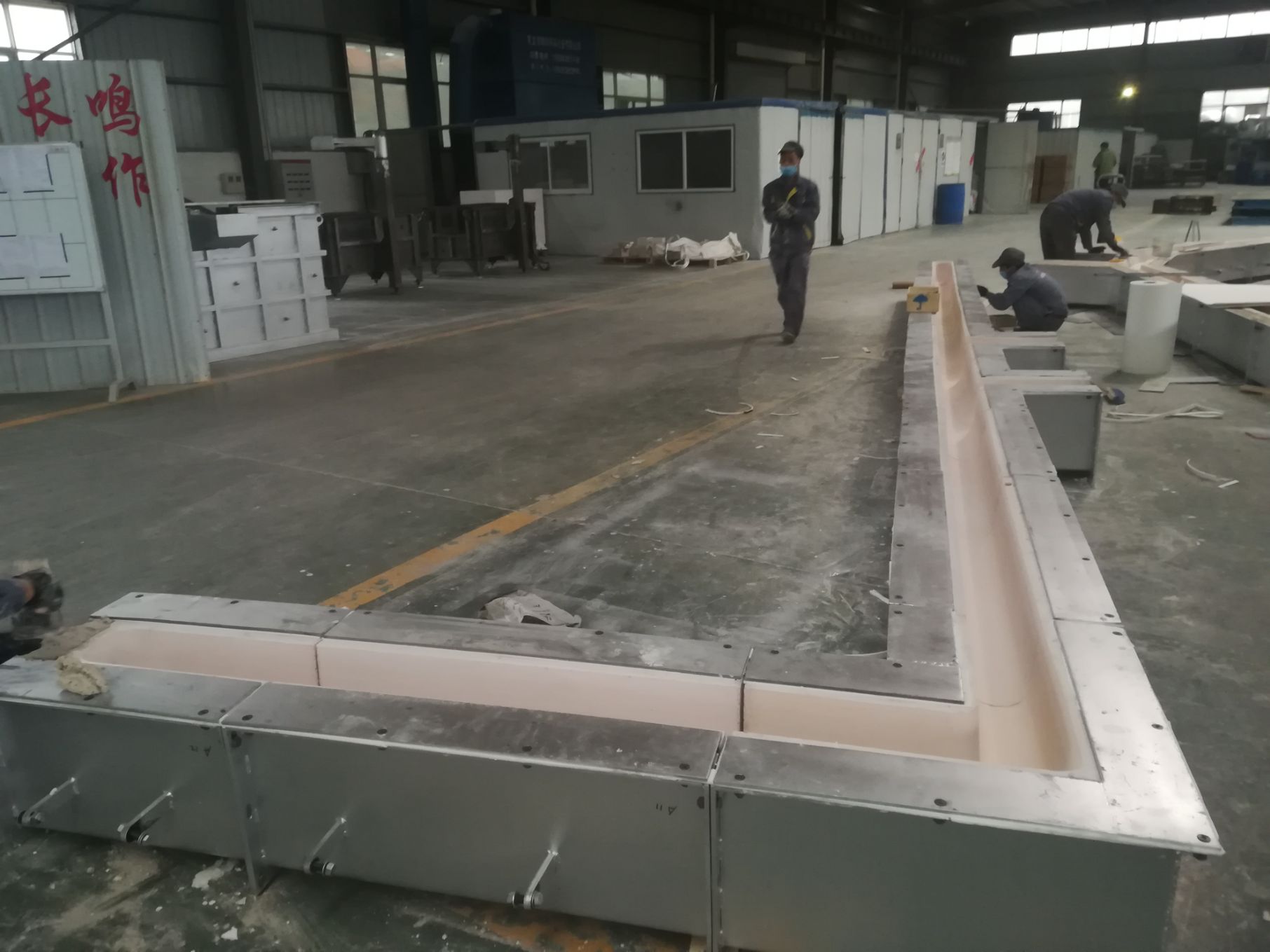

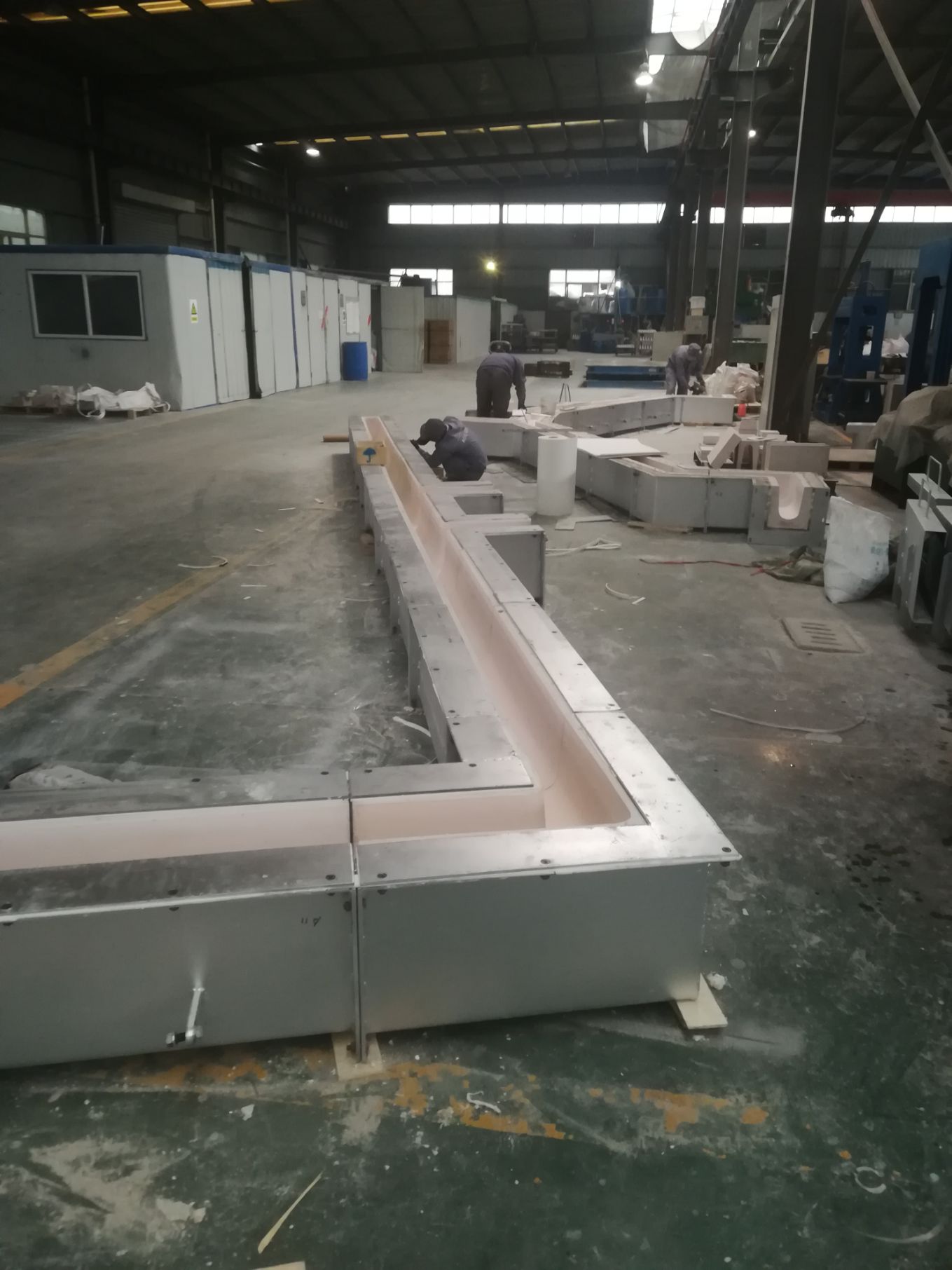

14 12月 AdTech Aluminium Launder

AdTech Aluminium Launder AdTech Aluminium Launder is also called silicate fiber trough, which is mainly used for the distribution and transmission of aluminum liquid with high heat preservation requirements, such as the active flow trough on casting and rolling, and the distribution trough on the same...