15 11月 Tap Out Cone For Aluminium Casting

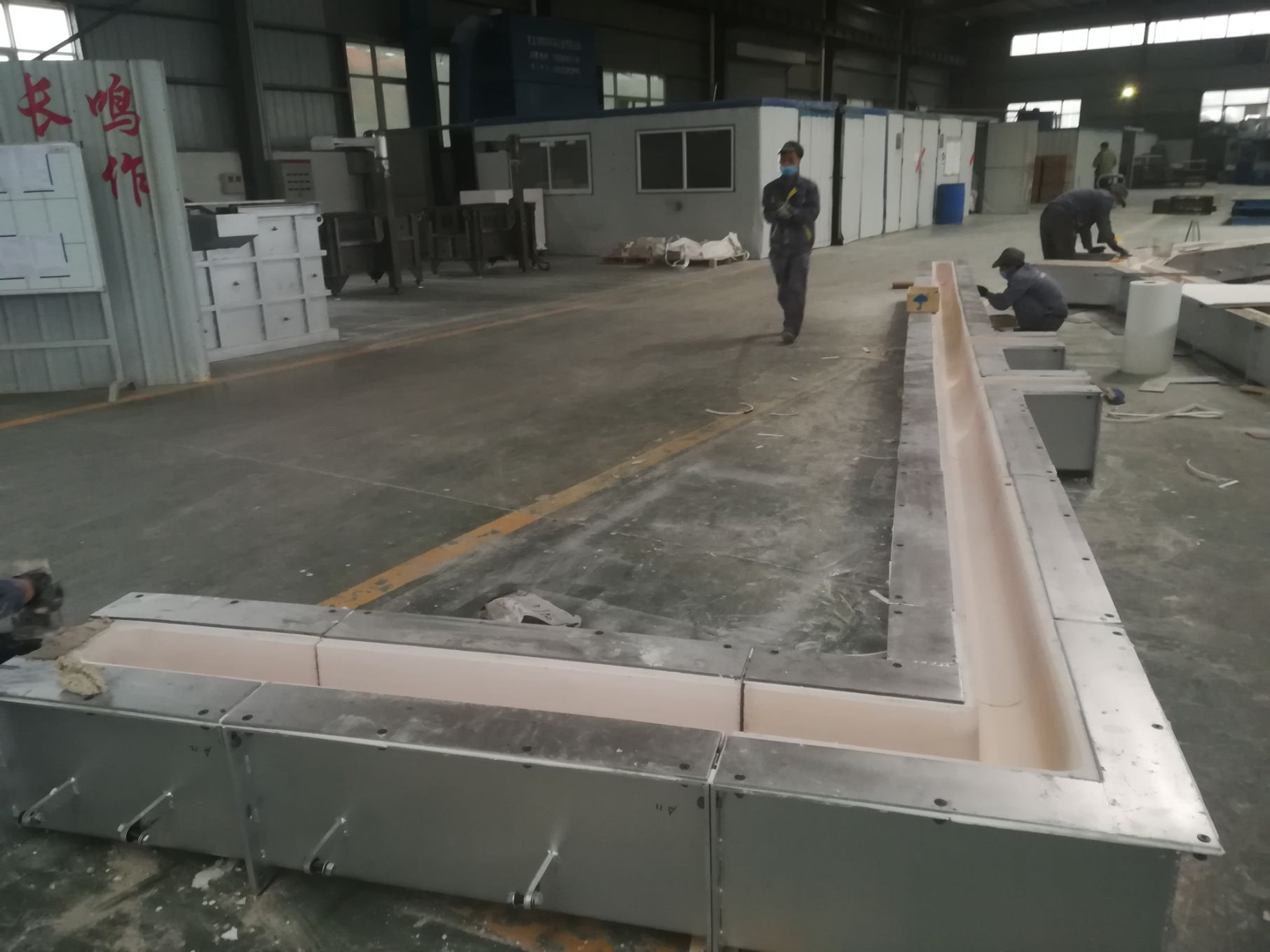

Tap Out Cone For Aluminium Casting Tap Out Cone For Aluminium Casting, also known as aluminum silicate plug, is called plug and plug; aluminum industrial plugging application: aluminum industrial plugging is mainly made of high-grade silicate fiber and other formulas by vacuum forming, and the plug...