30 11月 Tip Cavity

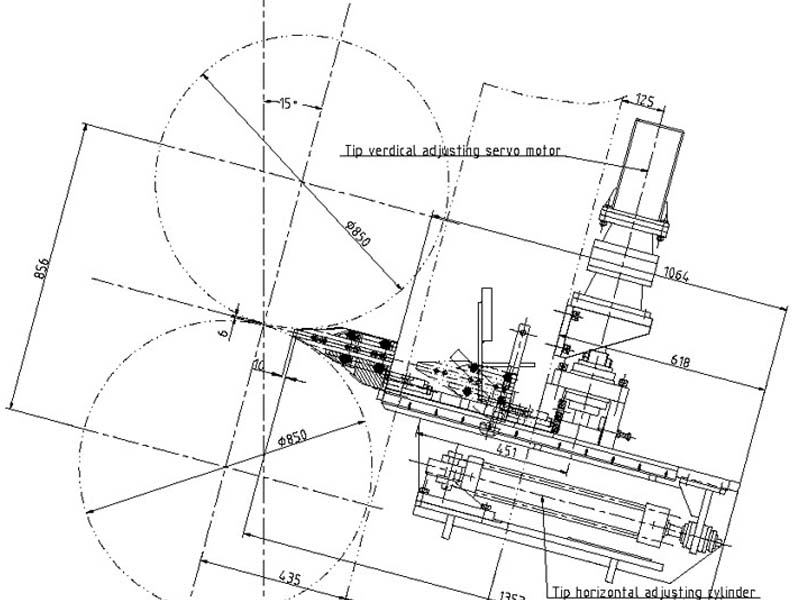

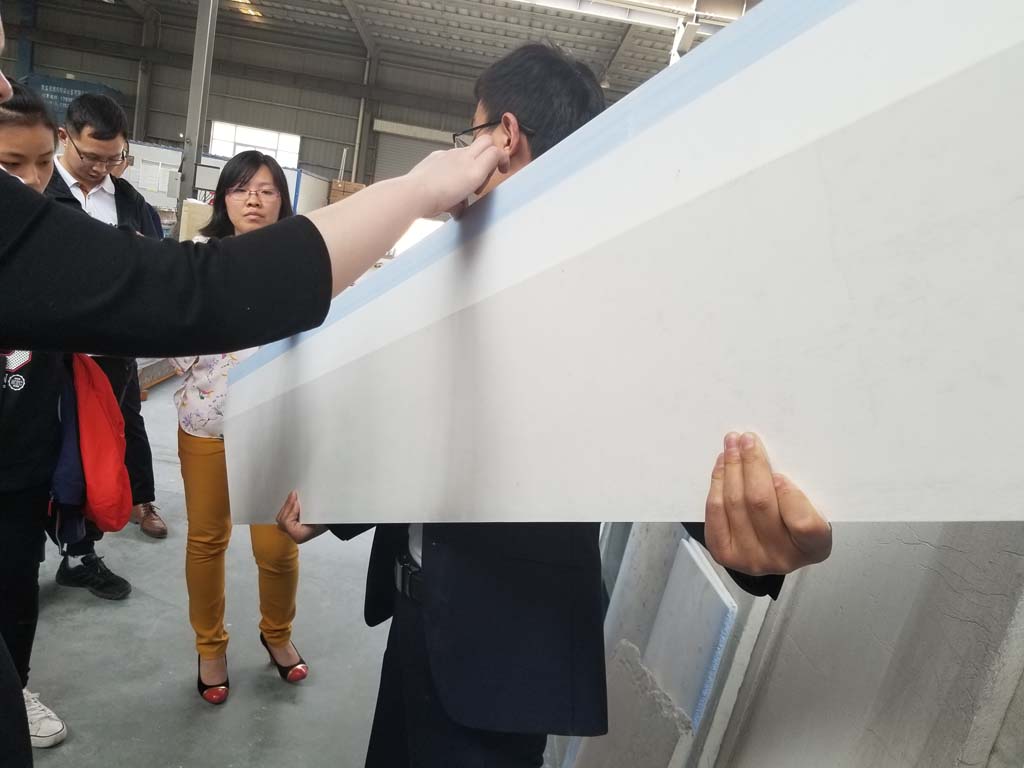

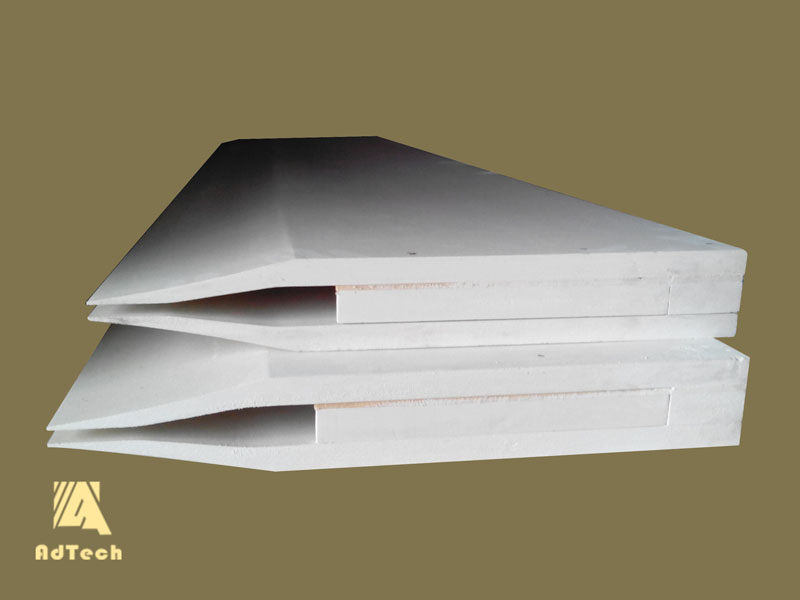

Tip Cavity is used in aluminum strip casting machine. The continuous casting process is that it is a comprehensive technology integrating solidification and deformation. The casting nozzle for the casting and rolling mill is a rigid, high-temperature resistant ceramic fiber board, which is made of high-purity...