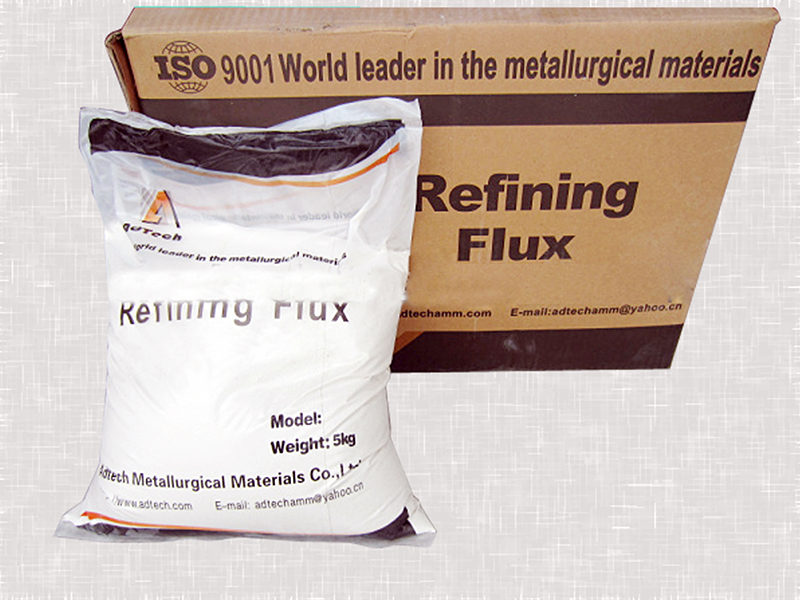

20 Nov Refining Flux

Refining Flux Flux Feature 1. white powder 2. No harm to the body 3.MOQ: 40kgs / carton 4. High quality with a competitive price 5. Supply stable and Capacity 500MTs. 6. We can provide the MSDS ( Material Safety Data Sheet ) Applications it is used for deslagging in the furnace wall and furnace...