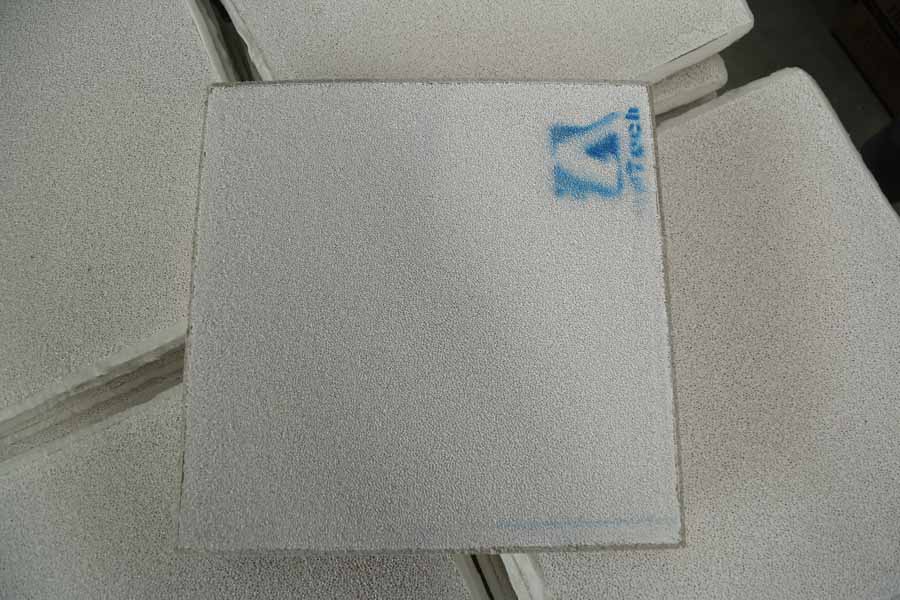

17 9月 Ceramic Filter Cff

Ceramic Filter Cff is widely used in the production of large aluminum processing enterprises in Russia, the Middle East and Southeast Asia.

During use, it is not only necessary to remove the aluminum melt inclusions, but also to avoid the blockage of the Ceramic Filter Cff and improve the service life of the CFF.

The melt is not filtered, which contains a large number of inclusions of different sizes. The coarse inclusions often form micropores first, which promotes the propagation of cracks, so the performance of the alloy is reduced.

If the melt is filtered, the inclusions in the alloy will decrease, the average spacing will increase, and the plastic zone at the crack tip will expand, which will lead to an increase in the resistance to crack propagation, which ultimately manifests as the performance of the alloy.

The filtering principle of Ceramic Filter Cff

The filtering of aluminum alloy melt includes surface filtering and internal filtering.

Surface filtration means that solid impurities are mainly deposited on the surface of the filter medium.

Internal filtration means that the molten aluminum carries inclusions in the Foam Ceramic Filter media along the tortuous channels and pores, which are directly intercepted, adsorbed, deposited, etc., collide with the pore wall and firmly adhere to the pore wall.

As the filtration progresses, the effective filtration section of the pores gradually decreases, the permeability decreases, and the filtration accuracy improves.

Ceramic Filter Cff and deep bed filtration belong to internal filtration, while tubular filtration belongs to dual capture of impurities on the surface and inside.

When the aluminum alloy melt is not filtered, a large number of inclusions will increase the viscosity of the aluminum alloy liquid and reduce the fluidity.During solidification, the interdendritic feeding channel is easily blocked, forming microscopic shrinkage and porosity.

At the same time, these impurity spots will also adsorb bubbles, form pores in the sample, become the source of microcracks, and reduce the performance of the alloy.

In addition, because the inclusions are mostly distributed in the grain boundaries after the alloy is solidified, the interface bonding force between the grains is reduced, resulting in intergranular fracture after the sample is stressed, which can be observed from the oxide film of the dendritic adhesion on the fracture Or inclusions can be confirmed. Metal Foam Filter Factory email: sales@adtechamm.com

The process by which inclusions in the matrix affect the fracture of the aluminum alloy specimen

When the specimen is subjected to tensile force, severe concentrated stress occurs at the crack front edge. When the tensile stress exceeds the yield strength, plastic deformation occurs near the crack tip first, forming a plastic zone, which leads to stress relaxation and blunt crack tip.

As the plastic zone expands, the inclusions at the front end of the crack enter the plastic zone.

Because the binding force between the inclusions and the matrix is relatively weak, under the action of tensile stress, the inclusions are separated from the matrix, forming the initial micropores.

Continue to increase the load, the internal necking between the crack tip and the micro-hole intensifies, causing the crack tip and the micro-hole to quickly aggregate, and the crack starts to expand forward.

Therefore, inclusions are conducive to the formation of initial micropores and have a greater impact on the propagation of cracks.

Sorry, the comment form is closed at this time.