04 4月 Ceramic Filter For Foundry

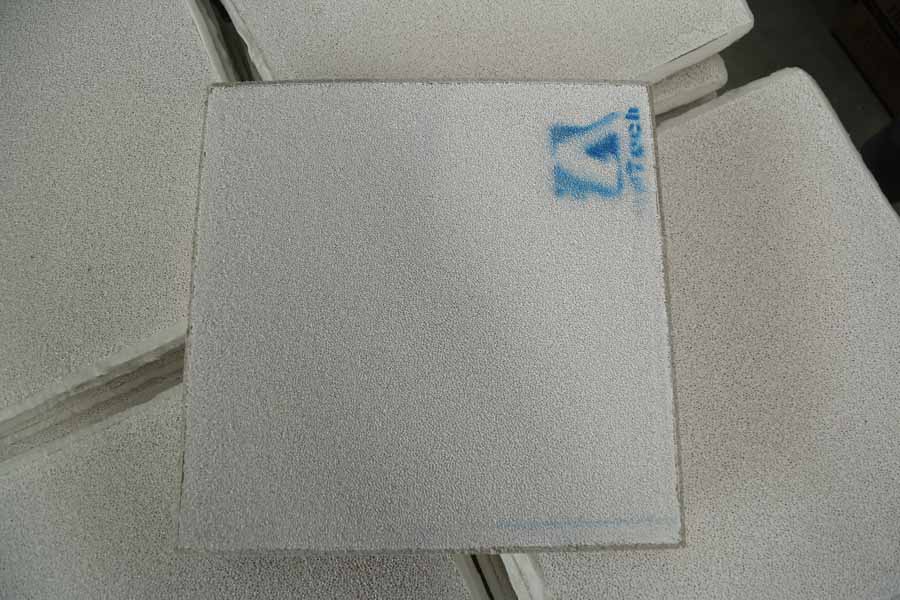

Ceramic Filter For Foundry

Ceramic Filter For Foundry is one of the core components of the ceramic filter. It is a new type of porous functional ceramic material, and its interior is covered with criss-crossing capillary pores (about 1 to 10 microns in diameter). This is the channel of the filtrate. This component is called the plate base layer.

The components of the ceramic filter plate are silicon carbide, corundum and other materials. The main components of the outlet and positioning base of the ceramic filter plate are composed of stainless steel or polymer material.

Aluminium is a metal found in the second row and Group 13 on the periodic table. It is the third most abundant element after oxygen and silicon to be found in the crust of the earth. Aluminium occurs naturally in compounds but never as pure metal. The process of extracting aluminum from its compounds is an elaborate and rather difficult. Aluminium is a useful and common metal that is known for being lightweight, its malleability, and corrosion resistant. Aluminium tends to be easier to recycle than to purify from ores. It is also safe enough when it comes in contact with skin and to be used around food.

Carried out an extensive programme on Ceramic Filter For Foundry.

In one section of this work the impact of adding a grain refiner based on the Al-Ti-B system was assessed.

They concluded that in case the incoming metal cleanliness was good then there was a minimal impact of the grain refiner on the performance of the filter.

However, if there is an artificially high inclusion loading from the metal (achieved by deliberately vigorously stirring the metal in the furnace), then the introduction of the grain refiner leads to a reduction in filtration efficiency.

In such a case there was a disproportionate release of inclusions from the filter compared to the incoming inclusion levels.

They assumed that the particles exiting the filter are agglomerates of inclusion species arising from the furnace metal interacting with particles from the grain refiner.

ADTECH keeps focusing on the manufacture of the metallurgical material.

ADTECH is one pioneer following by the International Enterprise, who keeps focusing on the manufacture of the metallurgical material.

1.Ceramic Foam Filter

2.Degassing Unit

3.Filter Box

4.Hot-top casting series

5.Roll casting nozzle

6.Flux series

7.Other Metallurgical Material

No Comments