16 4月 Ceramic Filter Foundry

Ceramic Filter Foundry

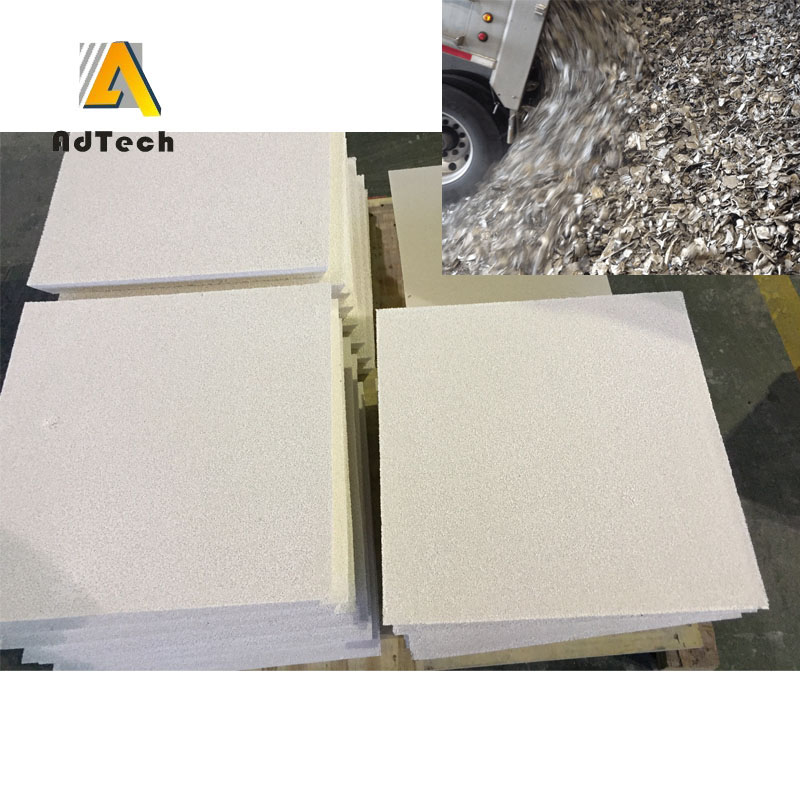

Ceramic Filter Foundry is made of high-quality high-purity zirconia, which is made of unique formula and advanced environmental protection technology. The three-dimensional network structure is uniform.

Ceramic Filter Foundry has excellent properties of high strength, stable texture, no slag, high temperature resistance and strong thermal shock resistance. It is suitable for purification and filtration of high temperature aluminum and aluminum alloy solutions. It can filter non-metallic slag and melt down to micron. Slag, etc., make the casting surface smoother and reduce machining loss.

The Ceramic Filter Foundry enables the aluminum liquid to fill the cavity more evenly. The molten metal has a higher turbulence tendency during casting. After the turbulent flow through the three-dimensional pore structure, it is finally converted into a very stable laminar flow, and the laminar flow fills the cavity. Better sex.

Ceramic Filter Foundry reduces the impact corrosion of metal solutions on the casting cavity, and significantly reduces scrap rate, reduces production costs, and increases labor productivity.

Ceramic Filter Foundry is widely used in aluminum casting workshops such as aluminum alloy cast rods, slabs, aluminum foils, aluminum cans and high-end aluminum profiles. The impurity particle filtration rate of 98 to 20 microns is 98.3%, which can help to obtain perfect aluminum products. Various specifications can be produced according to customer’s requirements, the range of 10ppi to 40ppi can be selected, and the maximum size can be up to 23 inches.

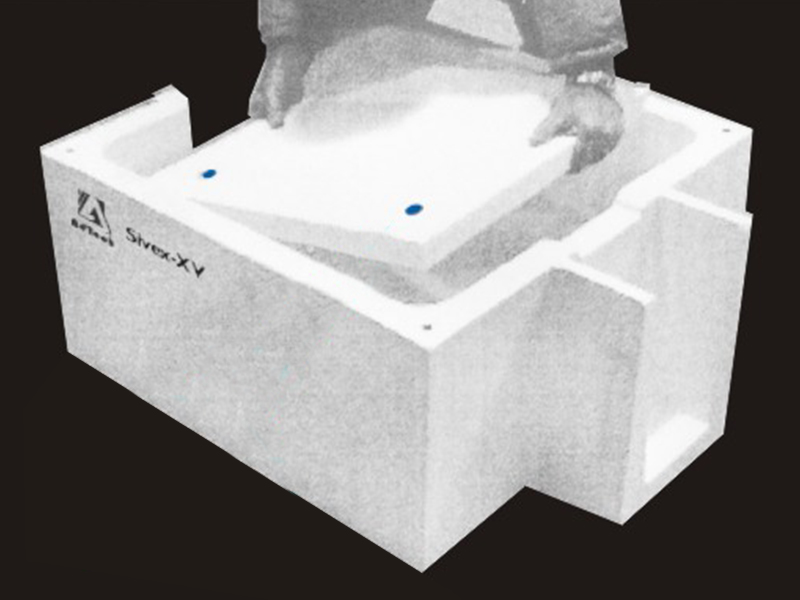

Ceramic Filter Foundry Installation

1. Clean the filter box.

2. Gently put the filter plate into the filter box and press the sealing gasket around the filter plate by hand to prevent the aluminum liquid from flowing.

3. Evenly preheat the filter box and filter plate to bring it close to the temperature of the aluminum liquid. Preheat to remove moisture and facilitate initial transient filtration. Preheating can be carried out using electrical or gas heating. Under normal circumstances, it takes about 15-30 minutes.

4. Pay attention to the change of aluminum hydraulic head during casting. The normal starting pressure head is 100-150mm. When the aluminum liquid begins to pass, the pressure head will drop below 75-100mm, and then the pressure head will slowly increase.

5. During the normal filtration process, avoid knocking and vibrating the filter plate. At the same time, the launder should be filled with aluminum water to avoid too much disturbance of the aluminum water.

6. After the filtration is finished, remove the filter plate in time and clean the filter box.

No Comments