24 12月 Ceramic Filter Indonesia Aluminum Smelter

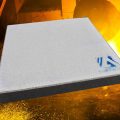

Ceramic Filter Indonesia Aluminum Smelter captures oxides and other inclusions in the aluminum melting process to clean aluminum and aluminum alloys.

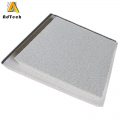

The aluminum liquid filter box is a special aluminum silicate filter box for the aluminum industry. Usually we call it a ceramic foam filter box, which is made of steel shell and aluminum silicate lining.

During the filtration process, the molten aluminum passes through the ceramic foam filter plate and flows in the zigzag channels and gaps of the filter plate.

The impurities in the aluminum melt are in contact with the surface of the filter plate channel under the effects of deposition, inertia and interception.

Under the action of pressure, friction, surface adsorption, etc., the impurities remain strong in the filter plate.

The Indonesia Aluminum Smelter introduced plate filter must be preheated before use.

The filter plate should be completely enclosed on the filter box to ensure that all aluminum water passes through the filter plate.

The total amount of filtration should not exceed the limit in the above table.

If the amount of slag in the aluminum water is too high, it should be adjusted by repeated filtering or reducing the output.

Indonesia Aluminum Smelter——For aluminum alloy profile manufacturers, the advantages of using ceramic microporous filter plates to clean aluminum

1. Improve extrusion efficiency

When using a filter plate to clean the extruded 6063 alloy billet, we tracked a specific die and found that the extrusion speed increased by about 20% and the productivity increased by nearly 15%.

2. Extend the life of the fungus and reduce the maintenance times of the fungus.

3. Reduce stress

When the 6063 alloy was cleaned with a filter plate, it was found that the squeeze force was more than 3% lower than the unfiltered squeeze force.

4. Greatly improve the surface quality of aluminum profiles.

from above. In terms of reducing production costs and improving product quality, the use of ceramic foam filter plates to purify molten aluminum has great advantages.

Indonesia Aluminum Smelter notifies the manufacturer of Ceramic Filter Indonesia Aluminum Smelter of the purchase e-mail from China filter plate sales@adtechamm.com.

The filter plate of the aluminum mill can effectively remove various fineness of micro-inclusions in the aluminum water, so that the aluminum water becomes a smooth laminar flow, which is good for filling.

It has good mechanical strength and chemical stability, as well as good aluminum cleanliness.

Strictly control the pore size and through-hole ratio to achieve stable filtration.

The filter plate is surrounded by thermally adjustable ceramic fiber gaskets, which helps the filter plate to be sealed in the filter box to ensure that no metal liquid passes through.

No Comments