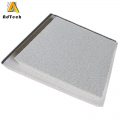

11 10月 Ceramic Filter Suppliers Inalum

Ceramic Filter Suppliers Inalum effectively removes large inclusions in molten aluminum, adsorbs micron-sized particles of fine inclusions, and plays a role in improving surface quality, improving product performance, improving microstructure, and increasing output.

Aluminum alloy casting process performance

It is generally understood as a combination of outstanding performance in the process of filling, crystallization and cooling. Fluidity, shrinkage, air tightness, casting stress, coiling.

These characteristics of aluminum alloy depend on the composition of the alloy, but also related to casting factors, alloy heating temperature, mold complexity, gate riser system, gate shape, etc.

Fluidity refers to the ability of the alloy fluid to fill the mold. The measurement of fluidity determines whether the alloy can cast complex castings. Eutectic alloys have better fluidity than aluminum alloys.

There are many factors that affect fluidity, especially the composition, temperature and solid particles of contaminants such as metal oxides and metal compounds in the alloy liquid. However, the fundamental external factors are pouring temperature and pouring pressure (commonly known as pouring). head). A sort of

In actual production, in addition to strengthening the smelting process (refining and slag removal), it is also necessary to improve the formability (sand mold permeability, metal release and temperature) without affecting the alloy. On the premise of ensuring the quality of casting, increase the casting temperature to ensure the fluidity of the alloy. A sort of

Ceramic Filter Suppliers Inalum purchase website www.adtechamm.com

The choice of agents must conform to the company’s development strategy.

AdTech is in a period of rapid development. He chose aggressive agents and agents who are actively developing business.

If the agent has been in the local business for more than 10 years, then we will give priority to you.

Indonesian agents should sell Ceramic Filter like this

A. Before developing new markets, clarify your channel goals and regional goals, and plan which foundries will sell products.

B. Visit various channels of the target market and ask the OEM purchasing personnel.

Recently, Indonesia’s Bintan Alumina Alumina Phase 1 million tons project completed the alumina output of 86,500 tons in September 2021, achieving the target of reaching the standard and output, and the energy consumption and product quality have reached the international advanced level.

The alumina project in Bintan Nanshan Industrial Park in Indonesia is implemented by the company’s indirect overseas subsidiary BAI. The construction site of the project is located on Bintan Island, Riau Islands Province, Indonesia. The planned alumina production capacity of the project is 2 million tons per year, which will be constructed in two phases. After the completion of the project, the company will be able to use Indonesia’s rich local bauxite and coal resources to produce alumina, achieve lower-cost alumina production capacity expansion, enhance the company’s profitability, and improve the company’s ability to resist risks.

No Comments