14 12月 Ceramic Filter Ykk Aluminum Indonesia

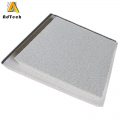

Ceramic Filter Ykk Aluminum Indonesia uses the internal three-dimensional structure to perform deep filtration, which can improve the purity of the aluminum liquid and meet the casting requirements of aluminum rods and aluminum ingots.

The ceramic foam filter has good thermal conductivity, stability and resistance to sudden changes in temperature.

The cleanliness of molten aluminum, that is, reducing the entry of molten aluminum, is a very important factor in the production of high-quality products.

The inclusions in the aluminum alloy cause the alloy structure to be disconnected, reduce the compactness of the product, cause corrosion and cracking, and reduce the mechanical properties of the final product.

Ykk Aluminum Indonesia engineers said that Ceramic Filter Ykk Aluminum Indonesia is a very important factor in the production of high-quality products.

Depending on the use of the final product, the degree of cleanliness of the metal is also different.

The thinner the required final product (tank, heat sink, etc.), or the higher the surface quality of the high-precision foil tape (PS board base, mirror decorative board, etc.), the higher the requirement for melt cleanliness.

During the remelting process, according to the cost of the furnace, clinker such as scrap steel, leftovers, plates, etc. is seriously oxidized and contains various non-metallic inclusions. The most common ones are aluminum oxide powder, oxide film, borides, and non-metals. Metal oxides such as magnesium oxide and magnesium chloride.

Inclusions exceeding the specified content can cause various problems, such as breaking the continuity of the aluminum alloy, forming pores, or breaking the strip.

When the aluminum strip is used as the base of the PS plate, the inclusions will form ordinary bubbles on the surface of the final product through rolling deformation.

In addition, some very hard solid inclusions (such as refractory particles) can damage the surface of the roll, leave repeated marks on the strip and become the source of cracks.

China Aluminum International and Indonesia PT STARMAS Aluminum Company conducted in-depth exchanges

On December 3, Bi Xiaoge, Vice President of China Aluminum International, met with Baharja, Executive Director of PT STARMAS Aluminum Company, in Indonesia. The two parties had in-depth exchanges on further strengthening communication and cooperation.

At the exchange meeting, Bi Xiaoge first congratulated PT STARMAS Aluminum Corporation for its achievements in the Indonesian aluminum processing market, and gave a brief introduction to China Aluminum International and CNMC Technology.

Baharja welcomed the visit of Bi Xiaoge and his delegation, introduced in detail the development of PT STARMAS Aluminum Company and Indonesia’s aluminum industry, and expressed his gratitude to Bi Xiaoge for sharing information on the aluminum industry in China and Indonesia.

The two parties conducted in-depth communication on the development status of China’s aluminum industry, the alumina production capacity in Indonesia, the alumina and electrolytic aluminum projects under construction in Indonesia, the potential consumer market for aluminum processed products in Indonesia, and the development trends of the aluminum processing industry.

The two parties stated that Chinalco International is an enterprise in the non-ferrous metal industry in China, with solid technical capabilities and rich experience in international projects. PT STARMAS Aluminum is an important aluminum processing enterprise in Indonesia with great development potential. Indonesia’s aluminum processing market has With broad development space, the two parties will further strengthen communication and strengthen cooperation in the digitalization of aluminum processing technology, intelligent upgrading and transformation, the application of aluminum processing products, the energy saving and consumption reduction of aluminum processing and production, and the deep processing of secondary aluminum and aluminum foil, in conjunction with the Indonesian government. The aluminum industry policy, the current situation of accelerated expansion of Indonesia’s upstream alumina and electrolytic aluminum production capacity, give full play to the advantages of both parties to seek more cooperation opportunities in the Indonesian aluminum processing market, and the two parties agreed to choose the opportunity to sign a strategic cooperation agreement.

Indonesia PT STARMAS Aluminum Company is an aluminum processing enterprise with development potential in Indonesia, which mainly produces aluminum sheet, strip and foil and construction aluminum profiles.

CNMC started to cooperate with PT STARMAS Aluminum Company in 2016. In 2019, it signed a supply contract for a 1550mm aluminum strip cold rolling mill and a 60-ton nitrogen-protected annealing furnace. The equipment is currently being installed and commissioned.

During the visit, Bi Xiaoge supervised the installation and commissioning progress of the 1550mm aluminum strip cold rolling mill and the 60-ton aluminum coil annealing furnace of CNMC Technology, learned in detail about the production situation of PT STARMAS Aluminum Company, and requested the CNMC Technology team to complete the installation on time Debug task.

No Comments