27 7月 Ceramic Filters Foundry

Ceramic Filters Foundry in China’s aluminum processing industry has been popularized, and there are two main modes of application in the purification of deformed aluminum alloy melt.

1.On the aluminum alloy semi-continuous casting line, the melt is refined with flux spraying in the furnace, and the foam ceramic plate is used for filtering outside the furnace.

The ceramic filter plate is replaced every time it is cast. Today, some aluminum processing plants add a trough-type online deaerator before filtering to improve the purification effect.

2. In the continuous casting and rolling line, the replacement cycle is determined according to the pressure difference before and after the Ceramic Filter Foundry.

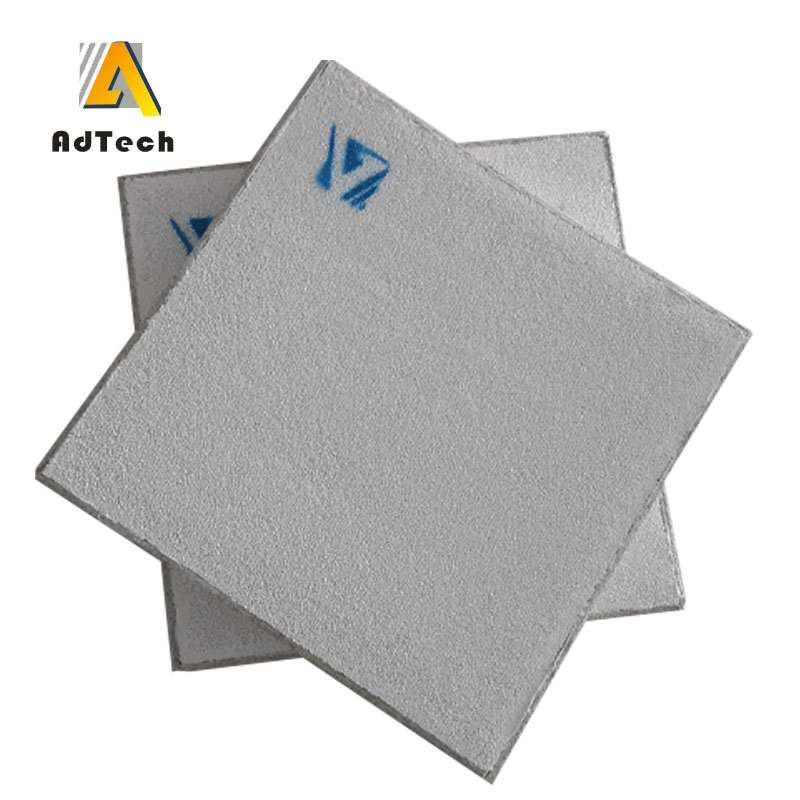

The size of the filter plate used is determined according to the unit time flow rate of the molten aluminum and the total amount of the molten aluminum.

The choice of foam ceramic filter plate with a large number of meshes is based on the cleanliness requirements of the final aluminum liquid.

The higher the requirement for the cleanliness of the molten aluminum, the smaller the selected pore size.

Ceramic Filters Foundry purification is the last process of aluminum liquid purification.

Before this process, flux spraying refining or on-line rotating degassing treatment has been used, so the impurity phase-hydrogen particles in the aluminum liquid that have not been removed are more fine and dispersed.

How to promote the accumulation of impurity phases and hydrogen adsorption in the foam ceramic filtration is particularly important.

With the development of science and technology, industrial production has higher and higher requirements for the purity and quality of aluminum and its alloy materials.

The traditional refining and degassing process cannot remove the small and suspended non-metallic inclusions in the molten aluminum. Therefore, people have studied many purification methods. According to their different mechanisms and forms, they can be divided into adsorption purification, physical purification and filtration purification [1. Filtration purification is to make the molten metal flow through a certain medium, this medium captures the inclusions according to a certain mechanism, thereby purifying the metal. In 1978, the United States developed a new type of filter-ceramic foam filter, which provides a high-efficiency filter for the production of cast aluminum parts.

The smelting of aluminum alloy is an important part of the aluminum alloy processing process, which is reflected in the alloying, purification and refinement processing technology of the smelting process. The removal of non-metallic inclusions in the aluminum alloy melt by the treatment of the flux in the furnace and the filtration of the ceramic foam outside the furnace has long become an important method for the purification of molten aluminum.

Sorry, the comment form is closed at this time.