25 Jun Ceramic Foam Filter Aluminium Podgorica

Ceramic Foam Filter Aluminium Podgorica is installed in the CFF box machine to filter the impurities in the aluminum alloy liquid to meet the high value-added, high-tech performance aviation, transportation and other aluminum alloy precision casting production.

The advantages of Ceramic Foam Filter Aluminium Podgorica include

1. Reduce the gas and inclusions contained in the casting, reduce the turbulence of the molten metal during filling, and reduce the surface defects of the casting.

2. Significantly reduce the rejection rate of castings, improve the compression and sealing performance of the castings, and increase the elongation and tensile strength of the castings.

3. Improve the surface finish of the casting, improve the fluidity of the molten metal, and improve the filling capacity of the melt.

4. Reduce processing time and tool wear, and improve the surface quality of castings.

Aluminium Podgorica chooses different filtering precisions during the use of ceramic foam filter

1. Aluminum alloy bar selection: 10-30ppi

2. Long-term casting options: 30-50ppi

3. High-quality aluminum profile or plate selection: 40 or 50ppi

4. Aluminum foil continuous casting and rolling options:> 50ppi

At present, there are various methods to remove these harmful substances and purify the aluminum melt.

According to different methods, it can be divided into two categories: in-furnace processing and continuous processing outside the furnace (that is, online processing).

According to the role, it can be divided into two categories: mainly degassing or deslagging. Ceramic casting filter manufacturer (www.adtechamm.com) introduced the use of foam ceramic filter plates to continuously filter aluminum melt. In addition to continuous treatment, the main purification operation is slag removal.

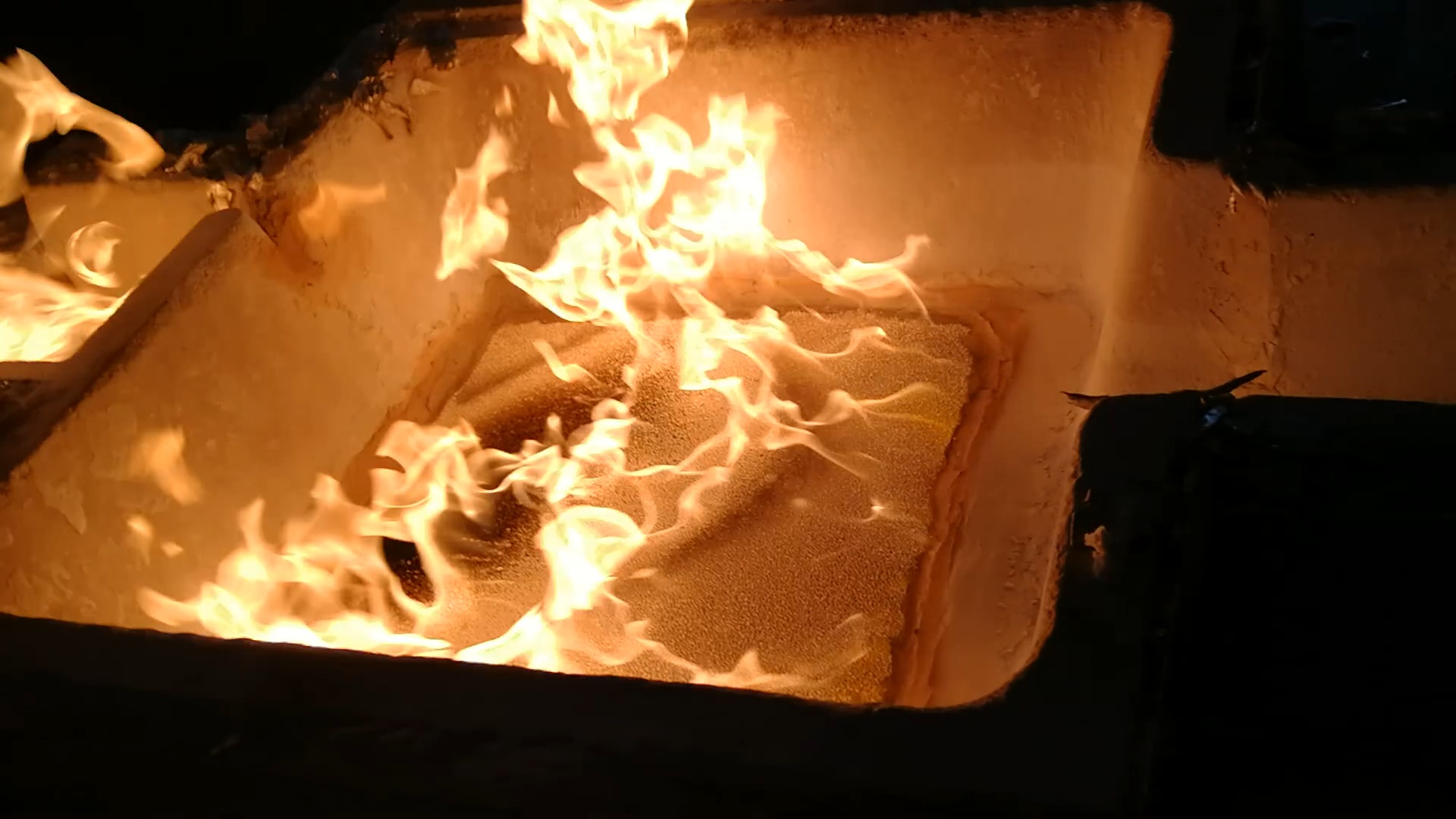

How to use ceramic filter plate

1. Clean the filter box

2. Gently put the filter plate into the filter box, and press the sealing gasket around the filter plate by hand to prevent the aluminum liquid from flowing by.

3. Preheat the filter box and the filter plate uniformly to make them close to the casting aluminum liquid temperature.

4. Pay attention to the changes of the aluminum hydraulic head during casting. The normal initial pressure head is 75-150mm. When the molten aluminum starts to pass, the pressure head will drop below 25mm. Then the pressure head will slowly increase.

5. After filtering, take out the filter plate in time and clean the filter Box.

No Comments