25 3月 Ceramic Foam Filter Aluminum Indonesia

Ceramic Foam Filter Aluminum Indonesia

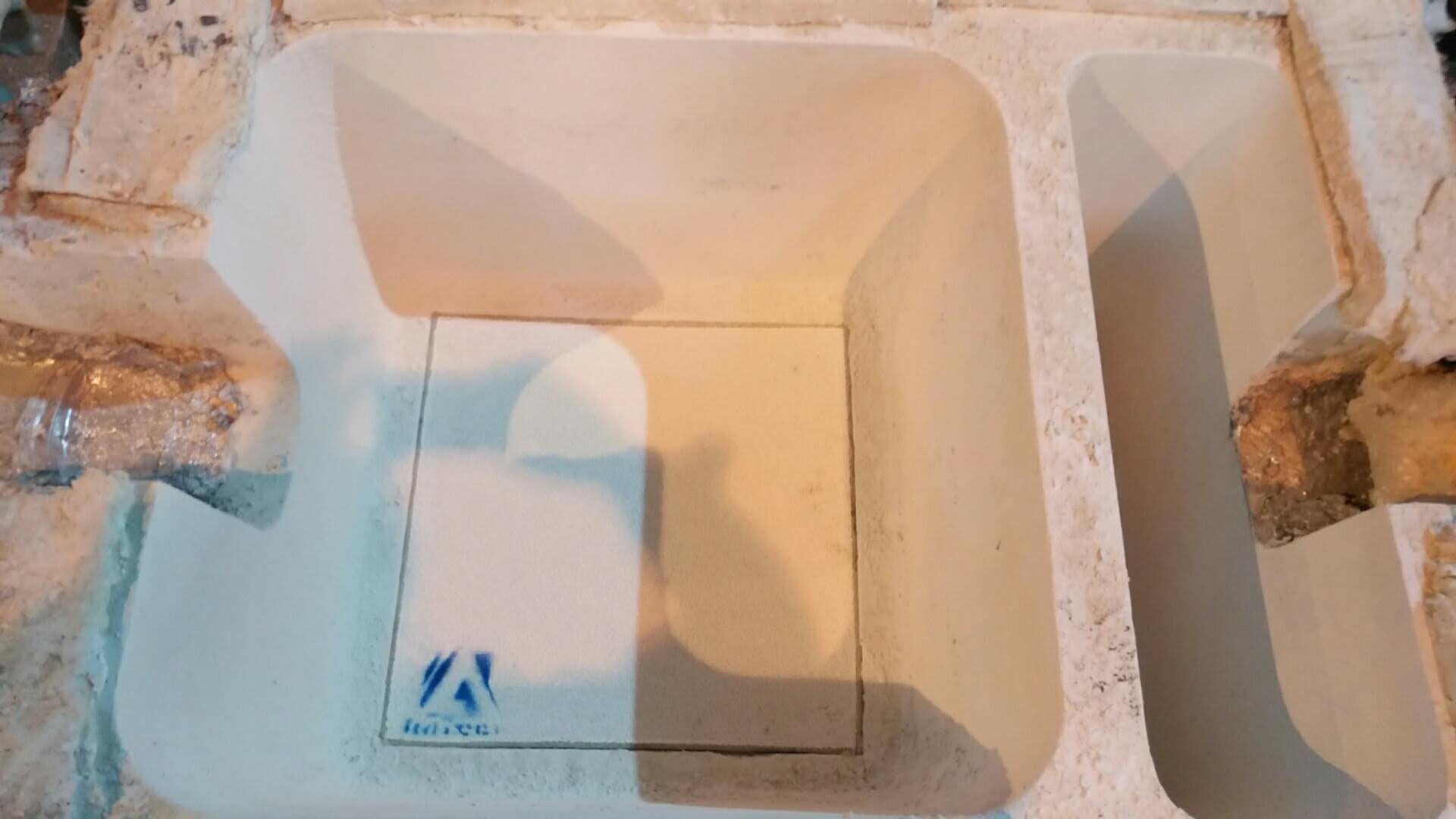

Ceramic Foam Filter Aluminum Indonesia uses a three-dimensional network structure and an organic bubble that communicates with the pores as a carrier, and invades it into the thixotropic alumina material slurry.

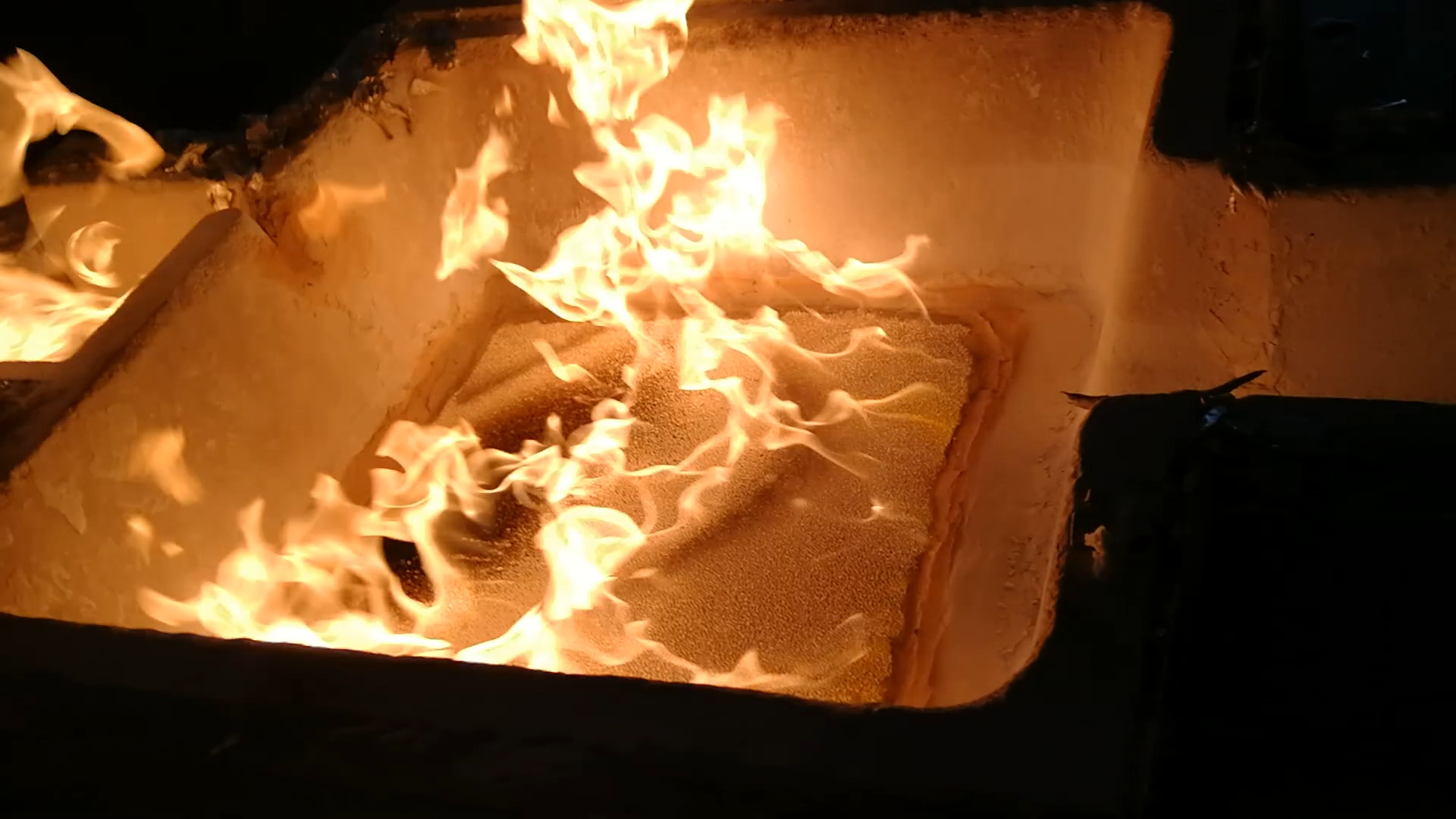

The four-square correction center distance automatic extrusion process is adopted to uniformly apply the slurry to the bubble skeleton of the carrier, and is baked and solidified at a high temperature of 1180 ° C.

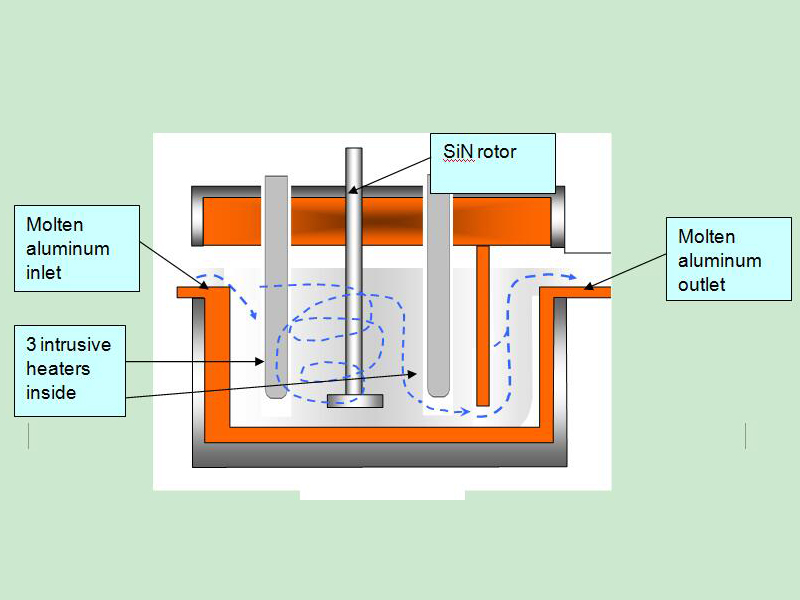

cAluminum Indonesia is installed in the filter box for the impurity filtration of aluminum alloy liquid, and it can meet the high-value-added and high-tech aluminum alloy precision casting of aviation and transportation. Such as: computer hard disk, PS board base for printing, cans, jet turbine engine fan blades and other products.

Advantages of the Ceramic Foam Filter from Adtech China

1. It adopts the principle of adsorption to filter, which can effectively remove large inclusions in aluminum liquid and effectively absorb fine inclusions of small size;

2. No slag, effectively reduce the pollution of aluminum liquid;

3. Good thermal shock resistance and improved corrosion resistance to molten metal;

4. Automated assembly line production, three calibration procedures, accurate size, and more suitable for the filter box;

5. Improve surface quality, improve product performance, and improve the role of microstructure.

The quality of Ceramic Foam Filter Aluminum Indonesia in the smelting of aluminum melts is important, which greatly affects the subsequent processing properties and the quality of the final product.

Therefore, all countries in the world attach great importance to the purification of aluminum melt.

There are many reasons for aluminum pollution. On the one hand, during the melting process, aluminum is exposed to the furnace atmosphere in a molten or semi-molten state, which is prone to oxidation and easily reacts with water vapor. Hydrogen is easy to form various forms of non-metallic slag, as well as coarse intermetallic particles and the like.

Some of the waste in the composition of the charge is brought into some non-aluminum impurities during the circulation. Since the waste comes from the process waste and waste of the various processes of the factory and the waste outside the factory, the route is different, the composition is complex, and the quality is also poor.

These impurities tend to cause bubbles and inclusions in the slab, which seriously affect the purity of the metal melt, thereby further affecting the processing properties, mechanical properties, corrosion resistance and appearance quality of the product.

Preheat before use,Ceramic Foam Filter Aluminum Indonesia

Preheating to remove water, to prevent cracks, and to facilitate the initial instantaneous heating and filtration; preheating can be carried out by electric or gas heating; under normal circumstances, it takes about 15 minutes.

1. In normal filtration, it is not necessary to carry out slag to avoid knocking and vibrating the filter plate; at the same time, the flow cell should be filled with aluminum water to avoid too much aluminum water.

2. After casting, the metal in the flow cell and the filter plate is drained; there is a vibrator placed on the filter plate and vibrated for one minute, and about 75% of the retained liquid metal can be shaken from the filter plate.

3. Finally clean up the perimeter, remove the filter plate after solidification

Alumina ceramic filter plates have excellent thermal shock resistance, strength and high porosity, which can filter and adsorb the inclusions as small as possible in the molten metal, and use their unique rectification to achieve smoothness. And rapid laminar flow, to prevent the entry of air bubbles, suitable for different refractoriness and casting speed requirements of the foundry industry; can significantly improve the quality of castings, is conducive to cutting, thereby reducing tool wear and reducing manufacturing costs.

Ceramic Foam Filter Aluminum Indonesia Effect

The use of alumina ceramic filters to clean aluminum liquids has brought great benefits to the strip foil and its products. As far as the aluminum alloy profiles are concerned, there are several advantages:

1. Improve extrusion productivity. When using filter plates to purify alloy extrusions, we have investigated a certain mold and found that the extrusion speed increased by about 20% and the productivity increased by nearly 15%.

2. Extend the life of the mold and reduce the number of mold repairs.

No Comments