21 2月 New Ceramic Foam Filter China for Aluminum Melt Purification

New Ceramic Foam Filter China for Aluminum Melt Purification

Filtration and purification mechanism of Ceramic Foam Filter China

1. By filtering the habit collision interception and diffusion interception, mechanical filtration such as friction and sedimentation, the filtration efficiency is proportional to the mesh aperture of the foam ceramic.

2. The effect of the sediment layer or the filter cake layer, with the deposition of particles in the melt and the bending and bending of the interconnected and convex and concave grid support wall, the miscellaneous

The ability to capture phase particles is increased.

3. The rough surface formed by the surface gap of the mesh truss body increases the interface between the aluminum liquid flow and the ceramic solid surface to promote the particles in the aluminum liquid flow.

The sub-flow is more disordered, which is beneficial for the solid particles to be trapped and deposited.

4. Due to the microscopic cracks and pinholes on the surface of the mesh truss, a fluoride flux with a strong affinity for particles such as Al2O3 is preliminarily deposited.

The entire filter cake layer effect and strong chemisorption force enhance the ability to capture the retained heterogeneous particles.

5. Furthermore, from the melting process of the metal melt structure and the temperature field effect of the transmission process, a dense bottom difference of the alloy solute is inevitably formed, and the metal melt is

Redistribution—integration—redistribution—integration, which is also a good alloying process, some high melting point metal phases and compound weight

The new aggregate grows up, and the small heterogeneous aggregates grow up to facilitate the filtration capture. This can also be obtained from the concentration of H, Al2O3, Fe phase and Ti phase before and after filtration.

Change to illustrate. In particular, two-stage filtration or hole gradient thick plate filtration is more obvious. Therefore, under the same preconditions, the new foam ceramics

The filter plate has high removal rate of heterogeneous phase of aluminum melt, and the change of static pressure difference before and after filtration is more change with time. The change of H content in aluminum melt before and after filtration

Also obvious. Of course, the smaller the foamed ceramic pores, the better the cleanliness of the aluminum melt.

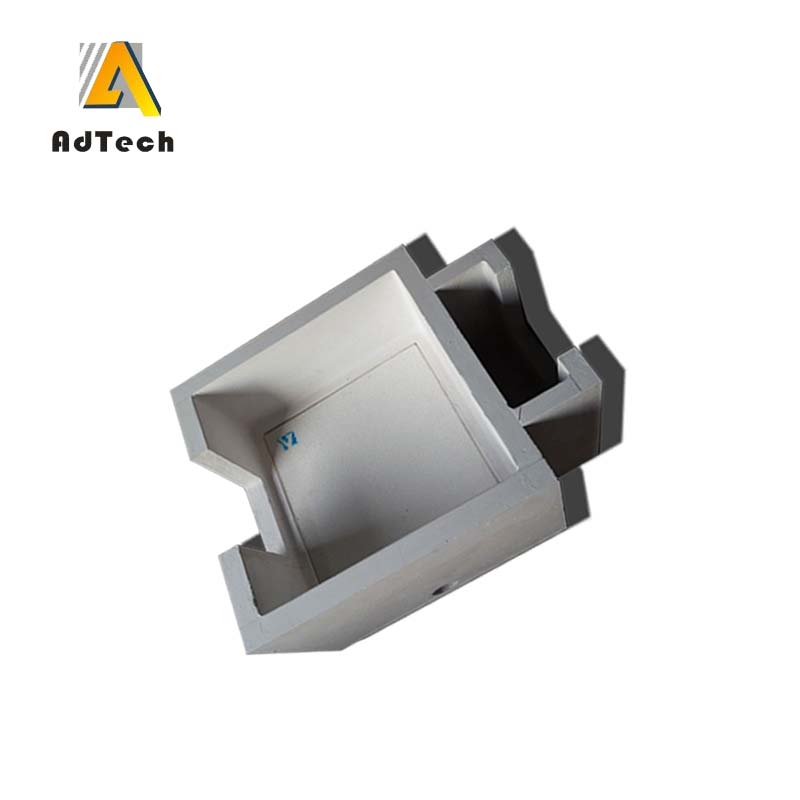

Correct selection of Ceramic Foam Filter China to improve the cleanliness of aluminum melt

1. The selection of the Ceramic Foam Filter China is firstly determined according to the impurity content in the aluminum melt and the quality requirement of the final cast product of the melt transfer flow rate.

The amount of impurities is high, and the quality of the cast product is general. The Ceramic Foam Filter China with larger mesh mesh can be selected, and a glass fiber cloth coarse filter is added in front of the Ceramic Foam Filter China. At this time, it is important to use a glass fiber cloth for coarse filtration in semi-continuous casting. It can intercept the slag and the slag washed by the launder when the eye is opened.

In order to prevent blockage of the filter plate.

The quality requirements of the cast products are high. The new type of Ceramic Foam Filter China with small mesh size is selected, which is the new type of Ceramic Foam Filter China, which achieves the ideal cleanliness and obtains good results.

3 filter plate specifications are selected according to the flow rate and total throughput of the melt. The flow rate is large, the total throughput is large, and the filter plate has small holes, and a larger size is selected.

2, choose the filter plate should also look at its color, shoot its body, burn its contents.

1 color is pure, no impurity, indicating that the material is uniform; the hand is not sticky, indicating that the surface is not sprayed with adhesive, it will not cause secondary pollution.

2 With one hand holding the filter plate, the other hand with the applause type, aptly tapping the filter plate, continuously dropping the ceramsite residue, indicating that it is a poor quality filter plate, which will cause secondary pollution of the aluminum liquid.

3 Use open flame or electric heating to heat red. Immediately cool at room temperature without cracking and slag, indicating that it is a good filter plate.

3. The effective specific surface area or porosity calculation of the foam should be carefully evaluated when purchasing the filter. The mesh surface homogenization state of the filter plate can be observed, and then the cross-sectional mesh homogenization state is observed. If possible, the porosity can be calculated by the drainage method. Three-dimensional mesh is homogeneous,

A relatively large porosity is an excellent foam ceramic filter plate.

No Comments