28 8月 Ceramic Foam Filter For Cast

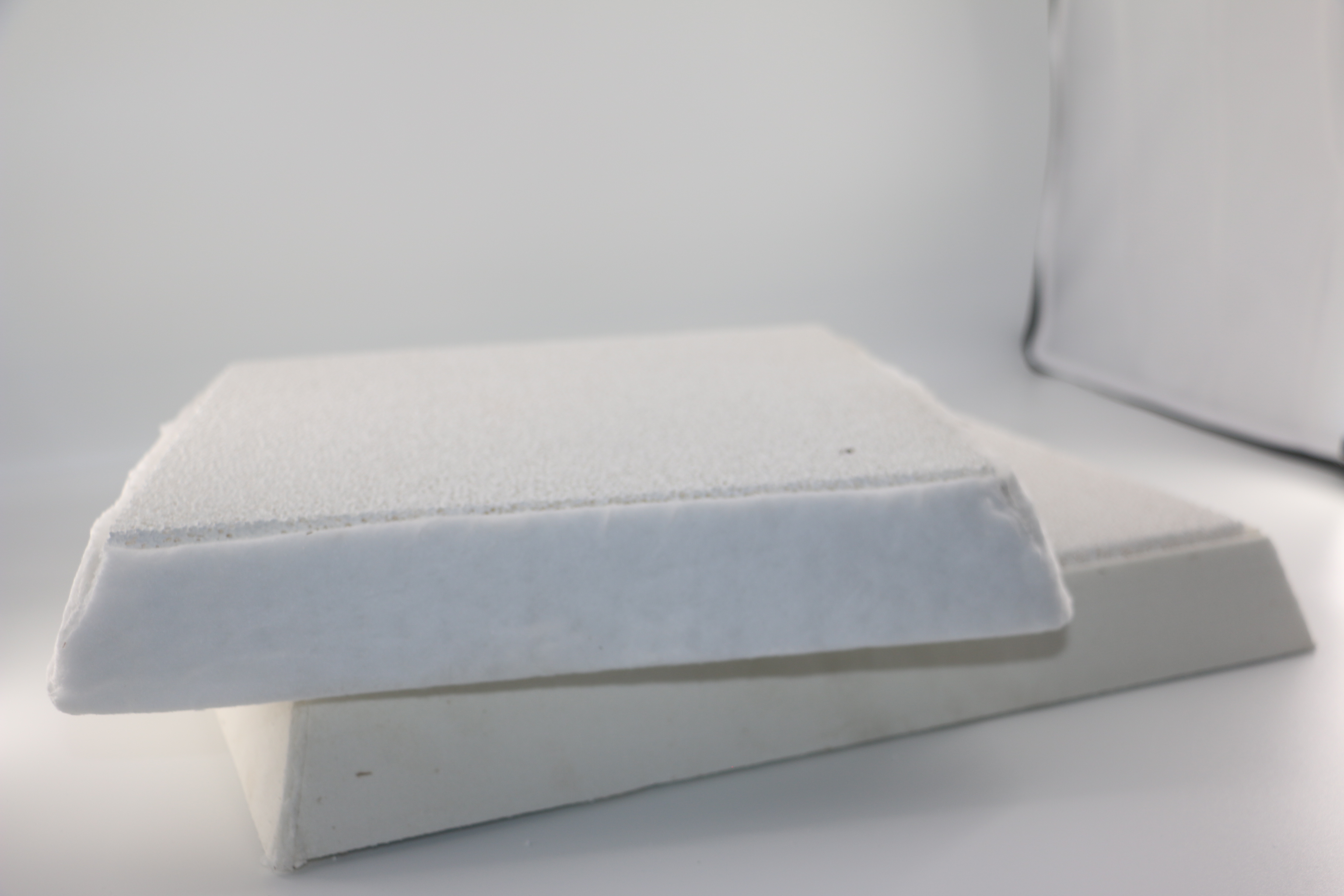

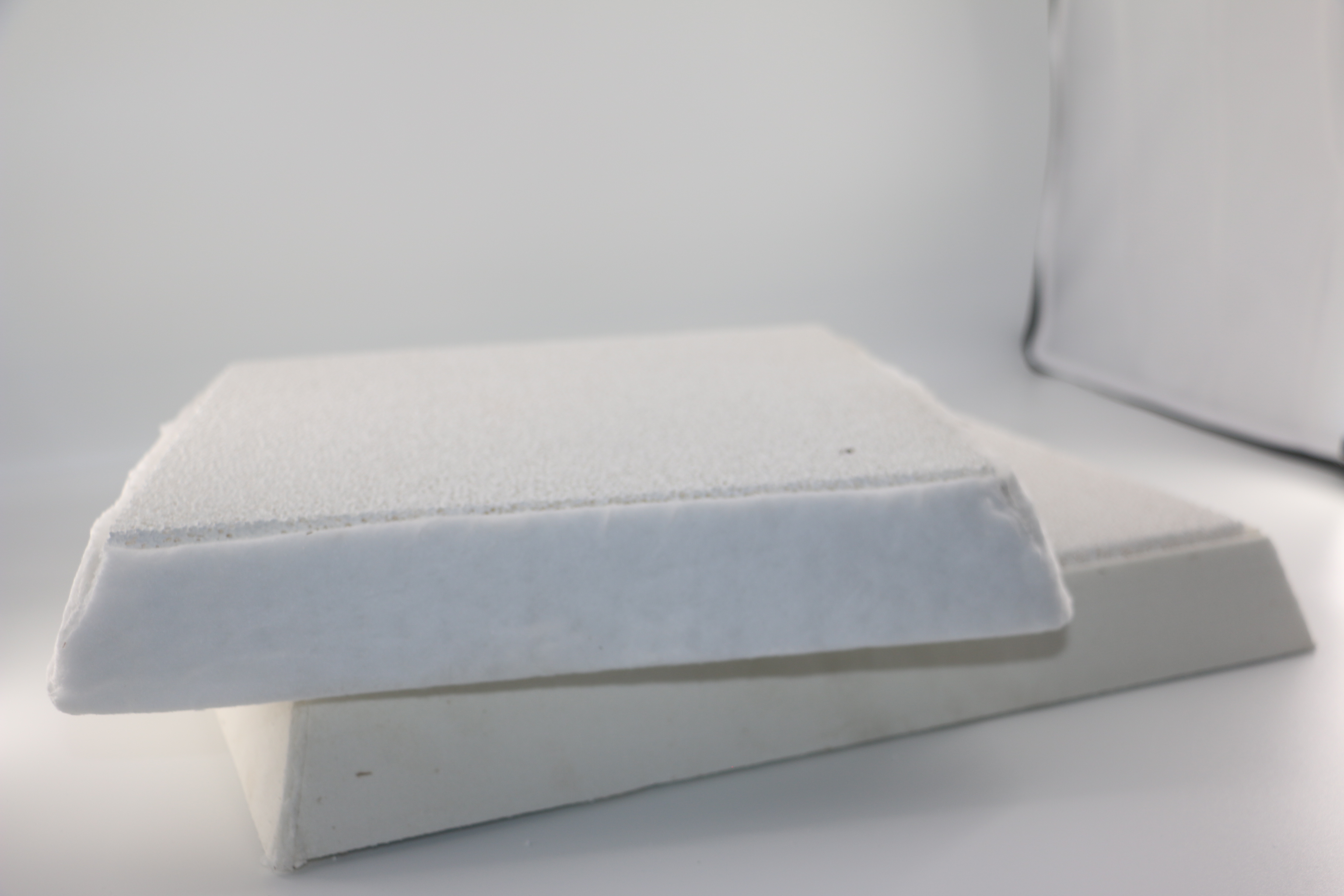

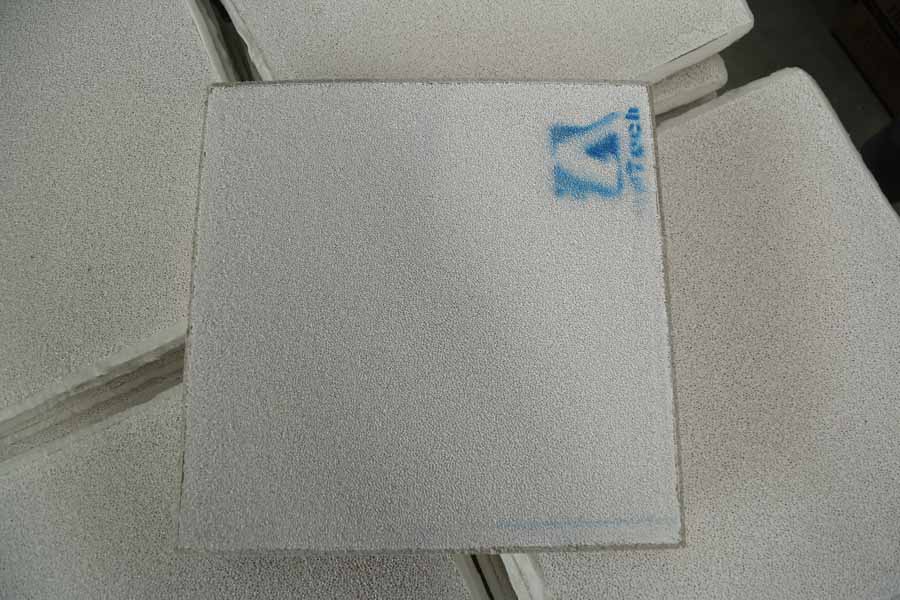

Ceramic Foam Filter For Cast is abbreviated as CFF, which is manufactured based on a solid network structure and a carrier with organic foam cells.

The preparation process is that the carrier is put into the thixotropic alumina slurry, and the angular center positive automatic extrusion process is adopted to uniformly deposit the slurry on the carrier foam skeleton after solidification.

After that, the carrier is made into a final product by firing at a high temperature of 1180°C.

The bowl is equipped with an open-cell foam filter material used to filter impurities in molten aluminum alloy, which helps to meet the production requirements of aluminum alloy precision castings with high added value and high technical performance (such as computer hard disks, PS boards). Used for printing, canning materials, fan blades of turbojet engines, etc.

Advantages of Ceramic Foam Filter For Cast

The filter adopts the adsorption principle, which can effectively remove the large inclusions in the molten aluminum and effectively adsorb the fine inclusions.

There is no debris, effectively reducing the pollution of molten aluminum. Ceramic Foam Filter For Casting – sales@adtechamm.com

Excellent thermal shock resistance, improve the corrosion resistance of molten metal.

Automatic production, 3 calibration procedures, accurate dimensions, and close installation of the bowl.

Improve the appearance and performance of the surface and purify molten aluminum.

The ceramic foam filter has a mesh structure with a certain strength and can withstand the pressure difference of the metal liquid surface and the impact of the metal flow, but the material structure is precise and fragile. Good quality, large surface area and good filtering effect.

Alcan Aluminium uses Adtech Ceramic Foam Filter For Casting in the production process of 6063 aluminum alloy, and makes the following summary.

For manufacturers of aluminum alloy profiles, using ceramic foam filters to purify molten aluminum has several advantages

1. Improve extrusion efficiency

The 6063 alloy extrusion billet is refined with the filter plate, and the specific die is tracked. The extrusion speed is increased by about 20% and the production efficiency is increased by about 15%.

2. Extend mold life and reduce mold maintenance times.

3. Reduce stress

The 6063 alloy melt was refined with a filter plate, and it was found that the extrusion force was more than 3% lower than that without filtering.

4. Greatly improve the surface quality of aluminum profiles.

from above. The use of ceramic foam filters to refine aluminum melt has great advantages in reducing production costs and improving product quality.

Sorry, the comment form is closed at this time.