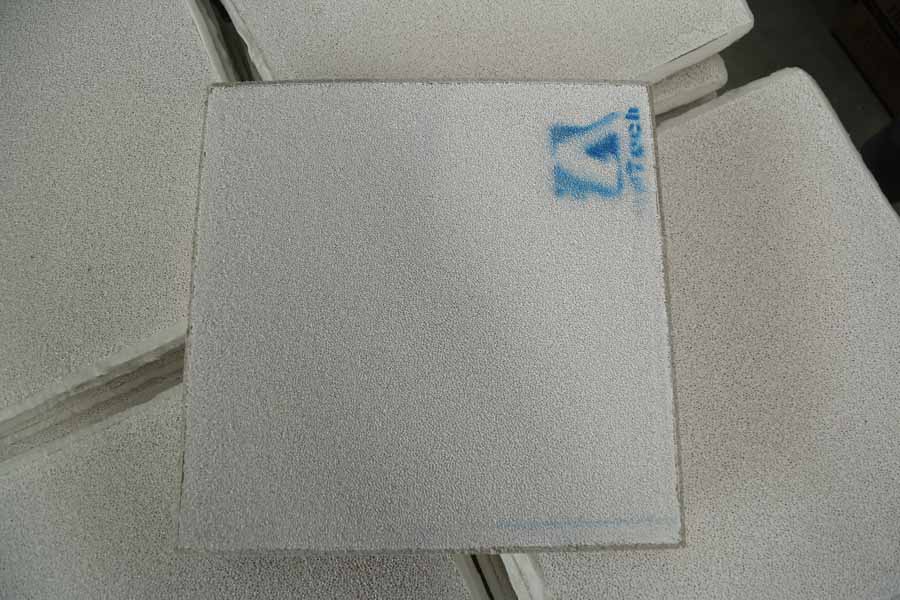

22 1月 Ceramic Foam Filter for Casting

Ceramic Foam Filter for Casting is mainly used in aluminum production and aluminum purification process. For aluminum products, high-quality ceramic filter plates with higher requirements will be more widely used.

Our ceramic filter plates adopt the formulas and processes of many well-known foreign companies and hire top domestic research talents.

The introduction of advanced production equipment and some raw materials from abroad originates from developed countries. Fully meet or exceed the performance level of similar foreign products.

Main functions of Ceramic Foam Filter for Casting

1. Foam Ceramic Filter can effectively remove bulk liquid aluminum inclusions.

2. The ceramic filter plate can remove small inclusions of a few microns in size that the molten aluminum is weak in the conventional process.

At the same time, because the filter can filter out the small splint material, the effective number of liquid aluminum nuclei is reduced, so that the liquid aluminum can nucleate in a larger swelling under cold conditions, the setting time is shortened, and the structure is refined.

3. Reduce the hydrogen content in liquid aluminum. Hydrogen can be adsorbed on some oxide inclusions, and the mixed oxide core can grow into bubbles and inclusions, so the gas on it can also be filtered out.

AdTech is a Sino-foreign joint venture that integrates the research and development, production and service of metallurgical materials.

AdTech is located in Wenxian County, China, covering an area of more than 700 acres. The existing standardized workshops and warehouses total more than 20,000 square meters.

Our office building has an area of 1,988 square meters and a registered capital of RMB 12,000,000.

AdTech serves customers in the Middle East (Bahrain Aluminum, Dubai Aluminum, China Aluminum Cable), Southeast Asia (Qili, GVA, Jindal, China Aluminum, China Zhongwang), Europe (Hydropower, Rusal) and other customers. AdTech is a long-term partner, a global supplier and solution provider of functional materials for the metallurgy and foundry industries.

Ceramic Foam Filter for Casting is based on a carrier with a solid network structure and combined with organic foam cells.

The production steps are as follows. The carrier is put into the thixotropic alumina slurry, and the square-centered automatic extrusion process is adopted to make the slurry dry and solidify and deposit evenly on the foam skeleton of the carrier.

The carrier is then calcined at a high temperature of 1180°C to form the final product.

The filter is installed in the filter housing to filter impurities in the molten aluminum alloy, helping to meet the production requirements of high value-added, high-tech performance aluminum alloy precision casting, such as computer hard disks, printed PS substrates, canned materials, turbines Fan blades of jet engines, etc.

Sorry, the comment form is closed at this time.