20 3月 Ceramic Foam Filter Manufacturer

Ceramic Foam Filter Manufacturer

Ceramic Foam Filter Manufacturer has been used in foundry production for decades.

But initially, only simple filters such as wire mesh, perforated steel plates, and porous cores were inserted into the gating system to filter out large inclusions.

Since the early 1960s, two-dimensional structural inner filter screens such as aluminum silicate fiber, molybdenum wire and boron nitride fiber have appeared Ceramic Foam Filter Manufacturers in Russia, the United States, Britain and the Middle countries, and have been applied in production. A certain effect has been achieved.

Since the first successful research on foam ceramic filters for aluminum alloys by Ceramic Foam Filter Manufacturersin 1978, foam ceramic filtration technology has developed rapidly.

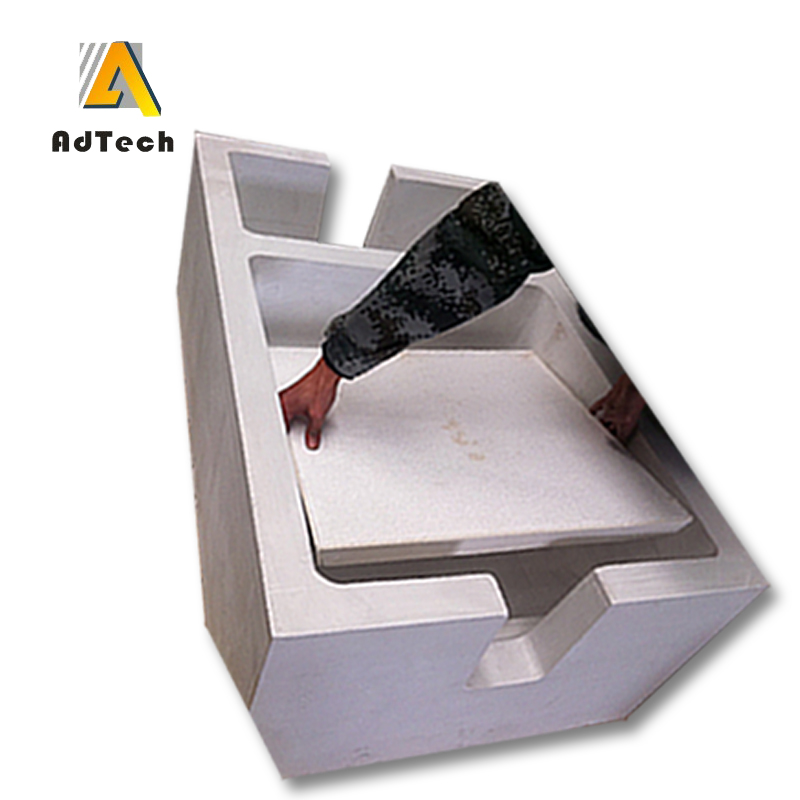

The filter uses polyurethane foam as a carrier, immersing it in a coating made of ceramic powder, binder, sintering aid, suspending agent, etc., and then extruding excess coating to uniformly apply the ceramic coating to the carrier. The skeleton becomes a green body, and the green body is dried and fired at a high temperature.

Ceramic Foam Filter Manufacturer Adtech

The shape and mechanism of the ceramic filter are similar to those of the disc vacuum filter. That is, under the action of the pressure difference, when the suspension passes through the filter medium, the particles are trapped on the surface of the medium to form a filter cake.

The liquid flows out through the filter medium to achieve the purpose of solid-liquid separation. The difference is that the filter medium-ceramic filter plate has micropores that produce capillary effect, so that the capillary force in the micropores is greater than the force exerted by the vacuum, so that The micropores are always kept in a liquid state.

No matter under what circumstances, the ceramic filter plate does not allow air to pass through. Because there is no air permeation, the energy consumption is low and the vacuum is high. The ceramic filter is mainly composed of a rotor, a stirrer, a scraper assembly, a slurry tank, Dispenser, ceramic filter plate, vacuum system, cleaning system and automation system and other components.

Effect of Ceramic Foam Filter Manufacturers

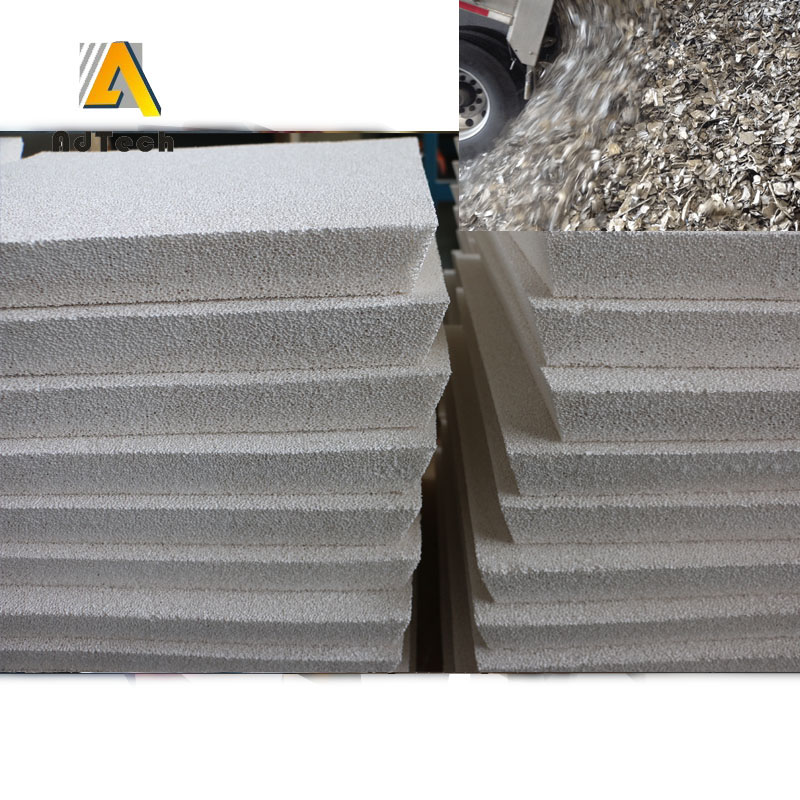

The use of aluminum industrial ceramic filter plates to clean aluminum liquid has brought great benefits to the strip foil and its products. As for the manufacturers of aluminum alloy profiles, there will be the following

Advantages:

1. Improve extrusion productivity

When using a filter plate to purify the alloy extrudate, we examined a mold and found that the extrusion speed increased by about 20% and the productivity increased by nearly 15%.

right;

2. Extend the life of the mold and reduce the number of mold repairs.

3. Reduce the pressing force.

When the alloy melt was cleaned using a filter plate, it was found that the extrusion force was more than 3% lower than that of the unfiltered.

4. Significantly improved the surface quality of the aluminum profile.

No Comments